Lens driver and process for manufacturing the same

A lens driving device and lens technology, which is applied in electromechanical devices, installations, instruments, etc., can solve the problems of focus deviation between the lens and the imaging element, and cannot provide a stable quality lens driving device, so as to achieve miniaturization and avoid interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the lens driving device of the present invention will be described below with reference to the drawings. Furthermore, a method of manufacturing a lens driving device and a portable device with a camera will also be described together. The structure of each embodiment is suitable for installation as a camera portion of a portable device such as a mobile phone, but it can also be installed in other portable devices such as a PDA (Personal Digital Assistant).

[0016] (the whole frame)

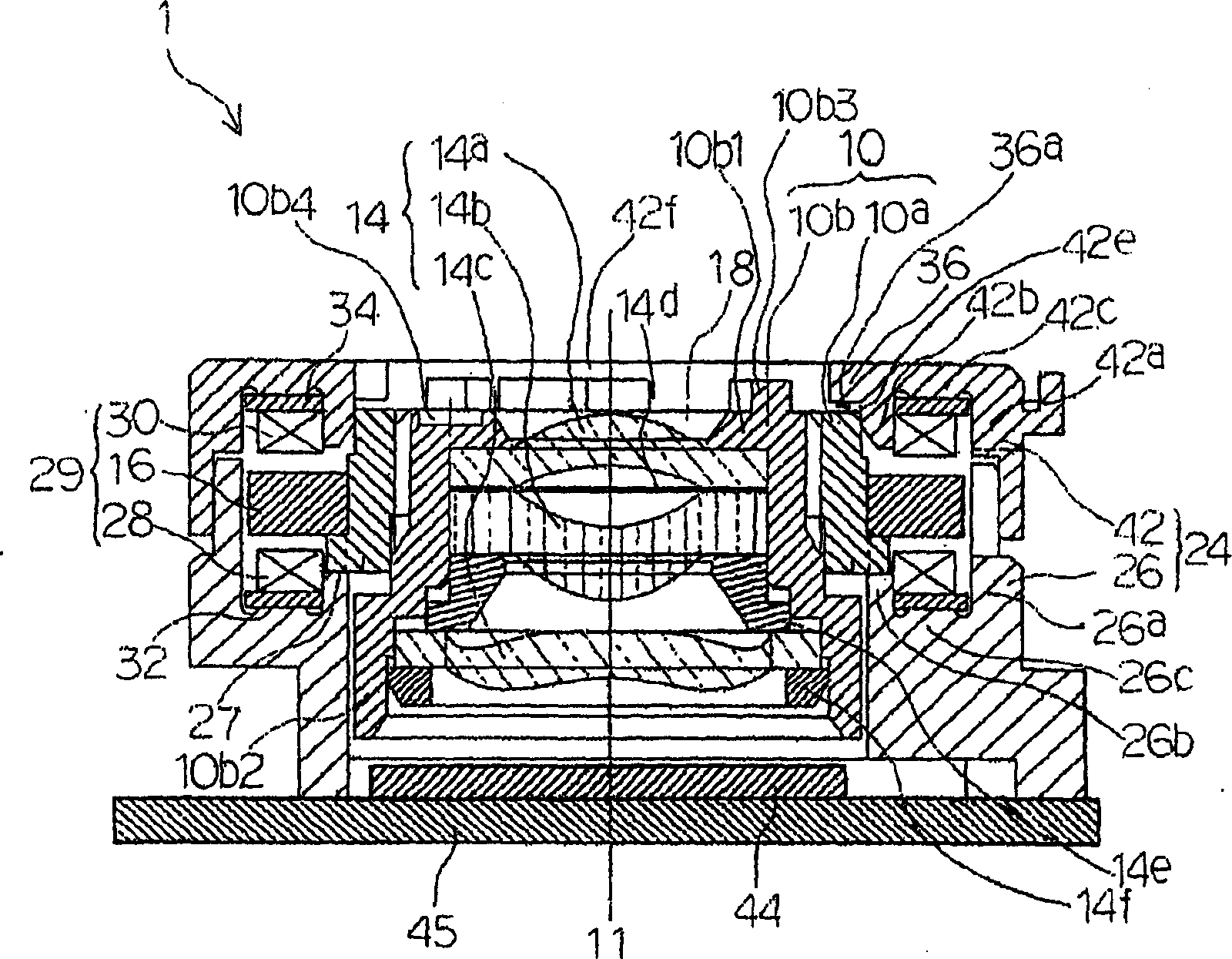

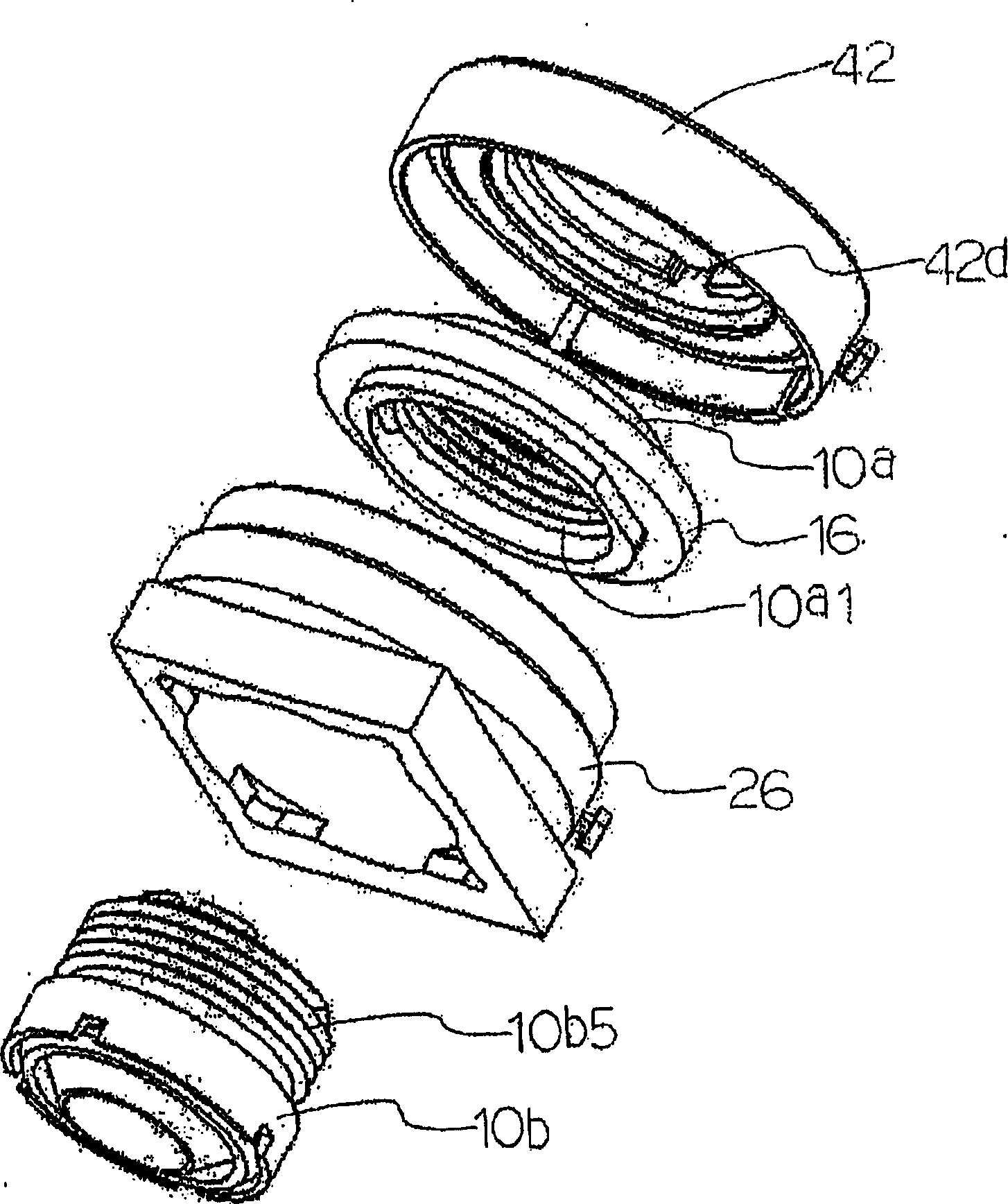

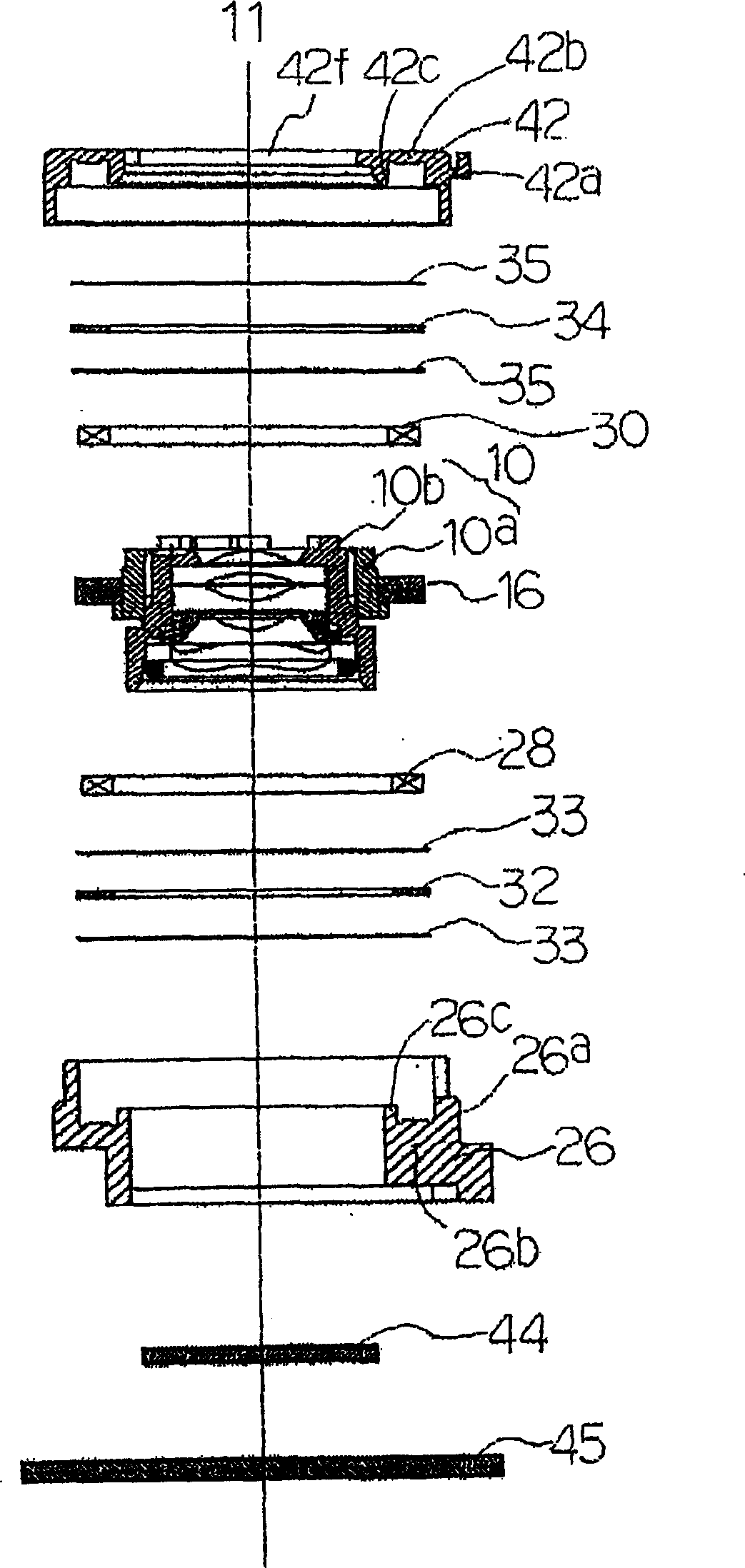

[0017] figure 1 It is a sectional view showing the lens driving device of the present invention. figure 2 yes figure 1 An exploded perspective view of the lens actuator shown.

[0018] Such as figure 1 or figure 2 As shown, the lens driving device 1 mainly includes: a moving lens body 10 that holds the imaging lens 14 of the camera; a magnetic drive member 29 that moves the moving lens body 10 linearly along the optical axis 11 direction of the lens 14; accommodates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com