Multi-layer packaging structure and producing method thereof

A packaging structure, multi-level technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the oxidative discoloration of phosphor powder and large-scale light decay, but cannot provide a comprehensive and complete solution, light-emitting diode oxidative discoloration, light decay level increase problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

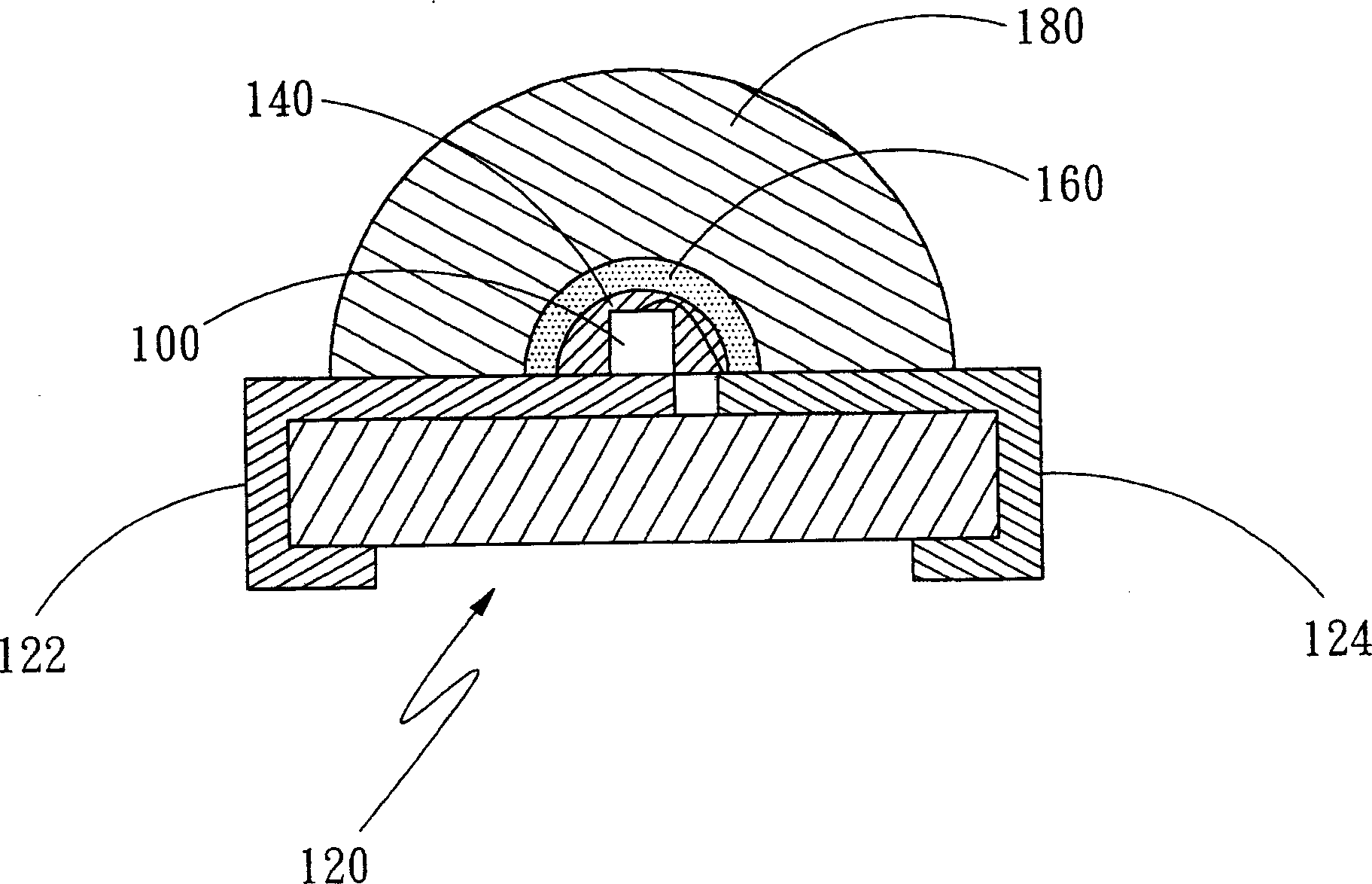

[0024] see figure 1 , figure 1 It is a sectional view of a preferred embodiment of the present invention. The present invention provides a multi-level packaging structure, which includes a light-emitting diode chip 100, which is arranged on the surface of a base 120, and the base 120 has a set of conductive circuits 122, 124, the conductive circuit 122, 124 transmit power to provide the light-emitting diode chip 100 to emit light, and an insulating material (not shown in the figure) is provided around the conductive lines 122, 124 to prevent the power from leaking out; a first colloidal layer 140 has light transmission , such as light-transmitting resin (EPOXY), used to coat the light-emitting diode chip 100; a light conversion layer 160, which can be spin-coated, sputtered, printed, The surface of the first colloidal layer 140 is completely covered by liquid droplets, formed first and then bonded, or other similar methods, and the light conversion layer 160 contains at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com