Structure for preventing water coming into turbine fuel and fuel leakaging

A steam turbine oil, steam turbine technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as oil ingress, and achieve the effect of preventing water ingress, preventing external leakage, and preventing external leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

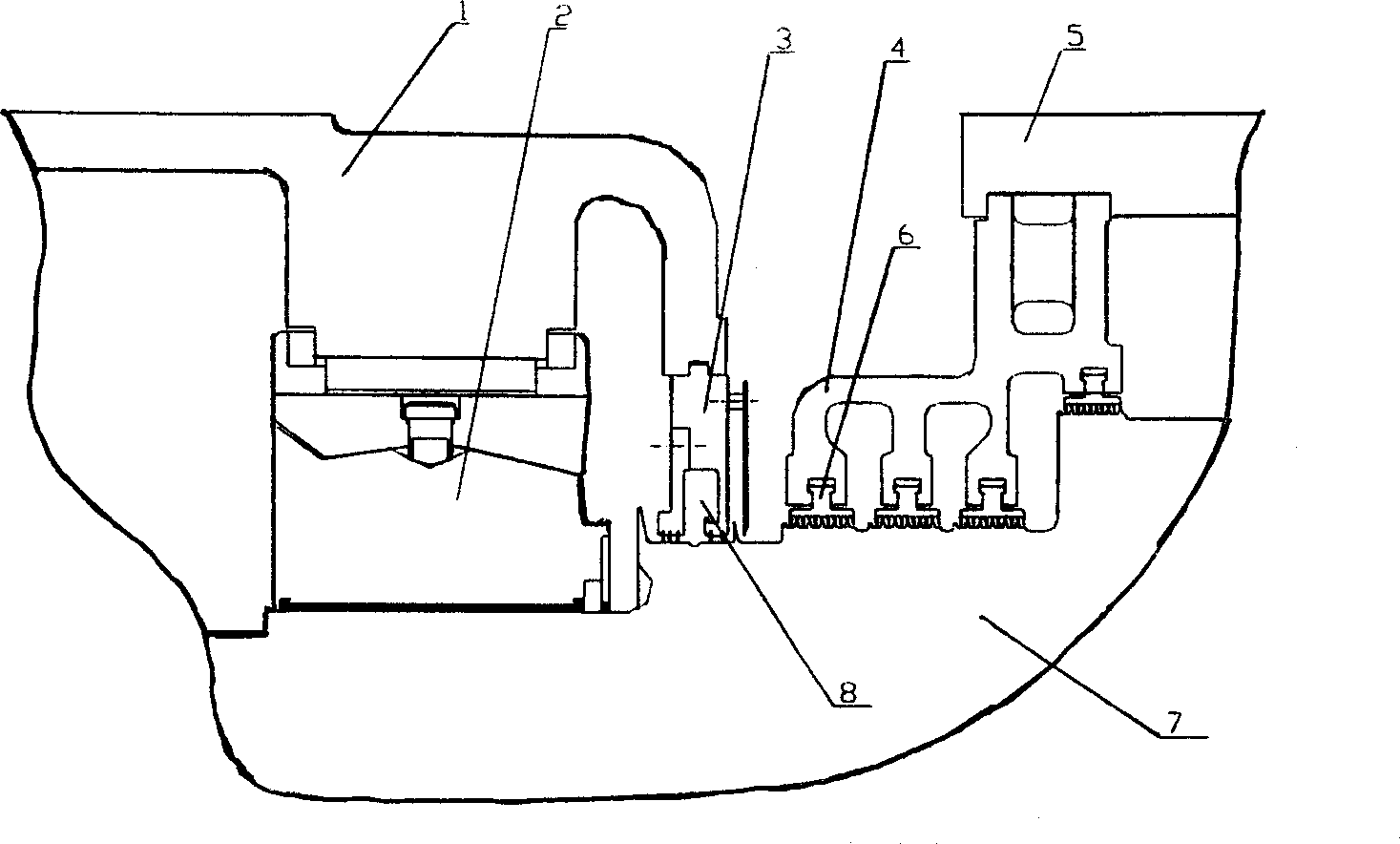

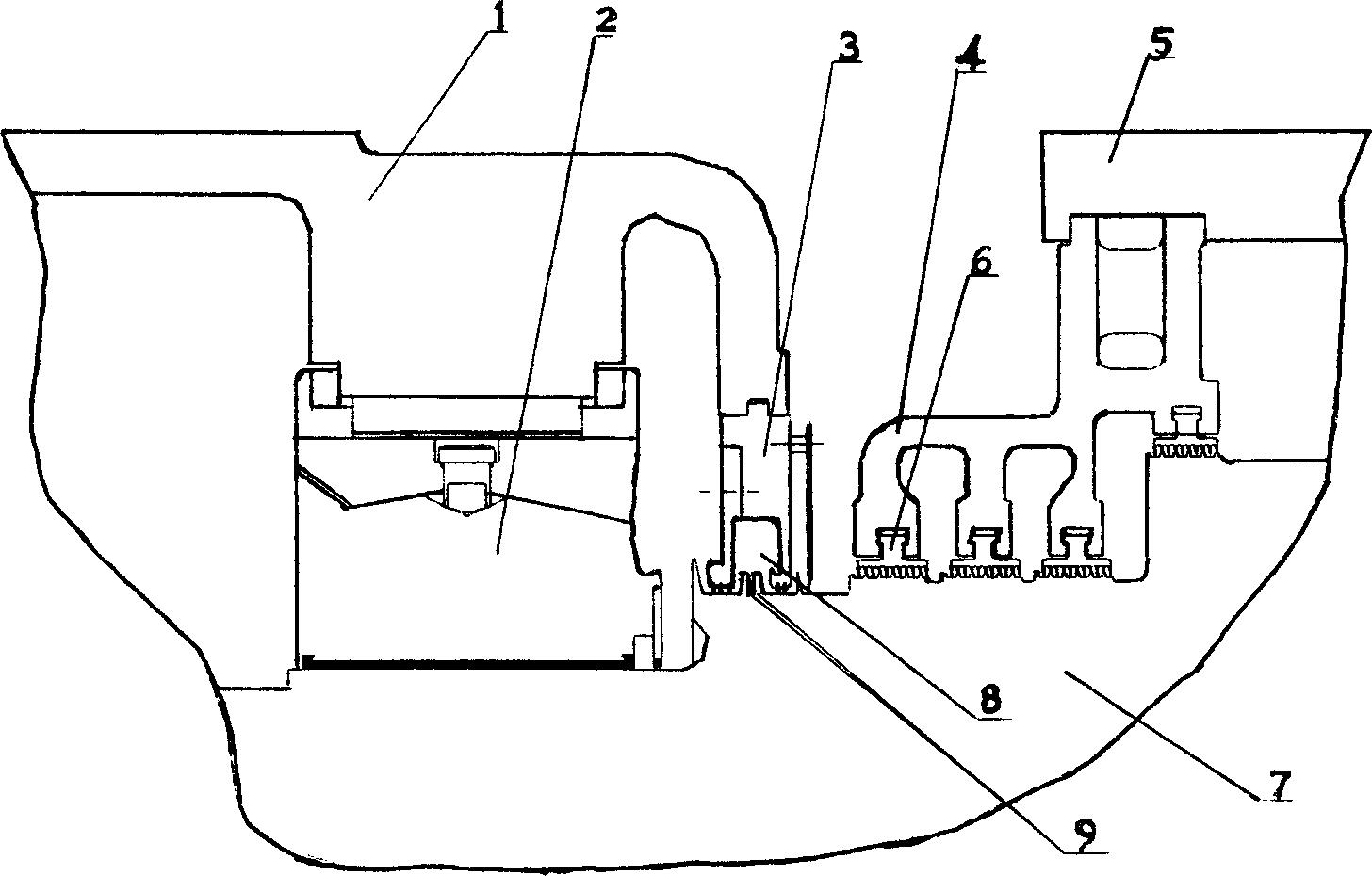

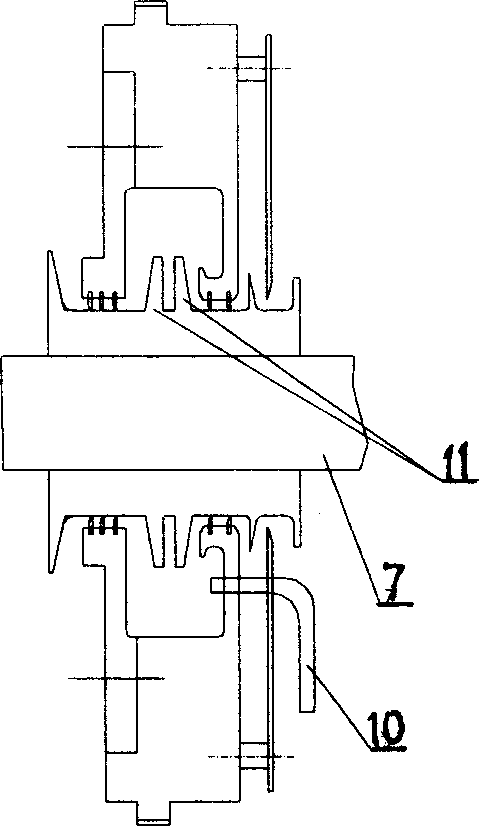

[0015] refer to Figure 1-Figure 4 , the present invention comprises the bearing box 1 on the rotor, the bearing 2, the oil shelf 3 and the oil shelf chamber 8, the cylinder 5, the steam seal body 4, and the steam seal 6. Directly process a miniature booster fan 9 at the place. Or the miniature booster fan 9 adopts an interference fit on the gear oil ring 11 and is sleeved on the rotor 7 . The oil stall chamber 8 is connected with one or several intake pipes 10 that can ensure that the oil stall chamber outside the micro booster fan is equal to the atmospheric pressure. The oil stalls 3 of these two structures need to be modified accordingly in order to adapt to this change, that is, one or several intake pipes need to be connected to the oil stall chamber 8 to ensure that the pressure of the oil stall chamber outside the micro fan 9 is equal to the atmospheric pressure At the same time, the length of the steam inlet pipe 10 should avoid the leakage of the steam seal 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com