Polyester melt POY, FDY compound silk spinning method

A polyester melt and composite spinning technology, which is applied in the field of polyester melt POY and FDY composite filament spinning, can solve the problems of not faster production speed, slow production rate, large equipment occupation area, etc., and achieve high-quality products The effect of maintaining stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

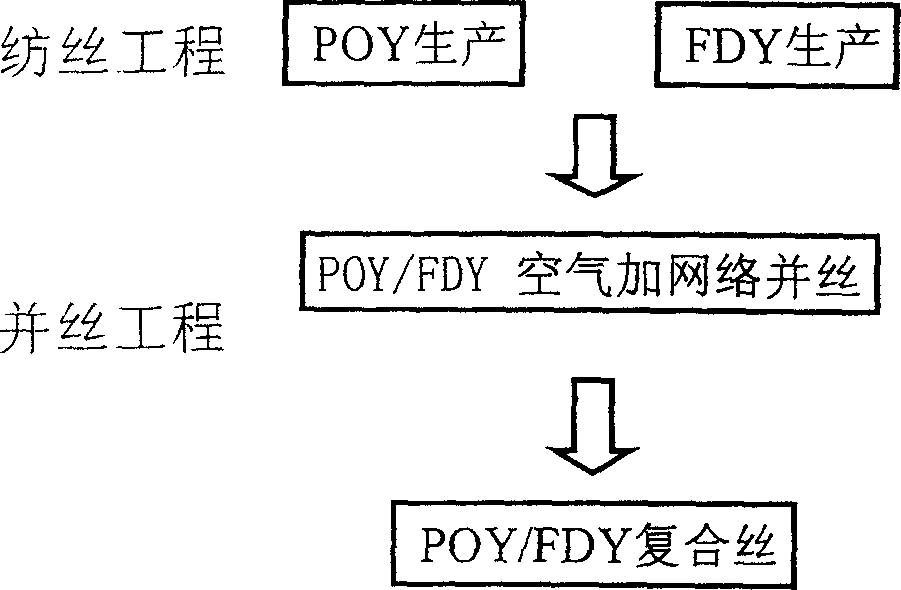

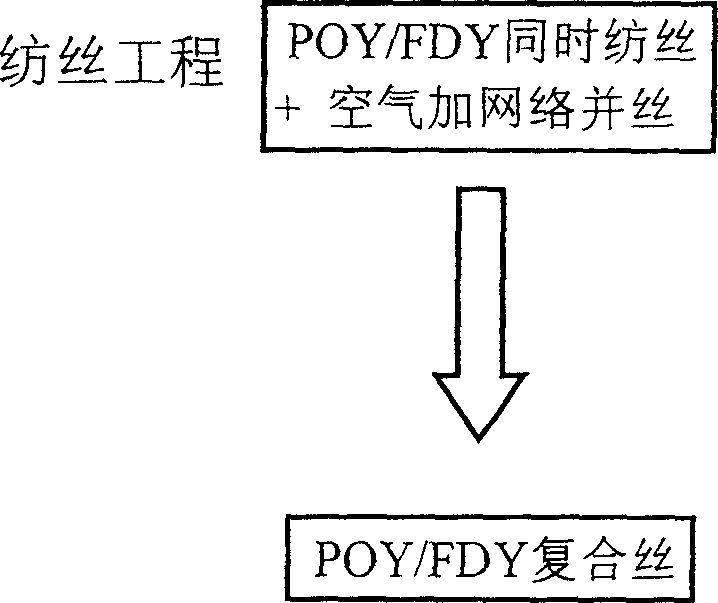

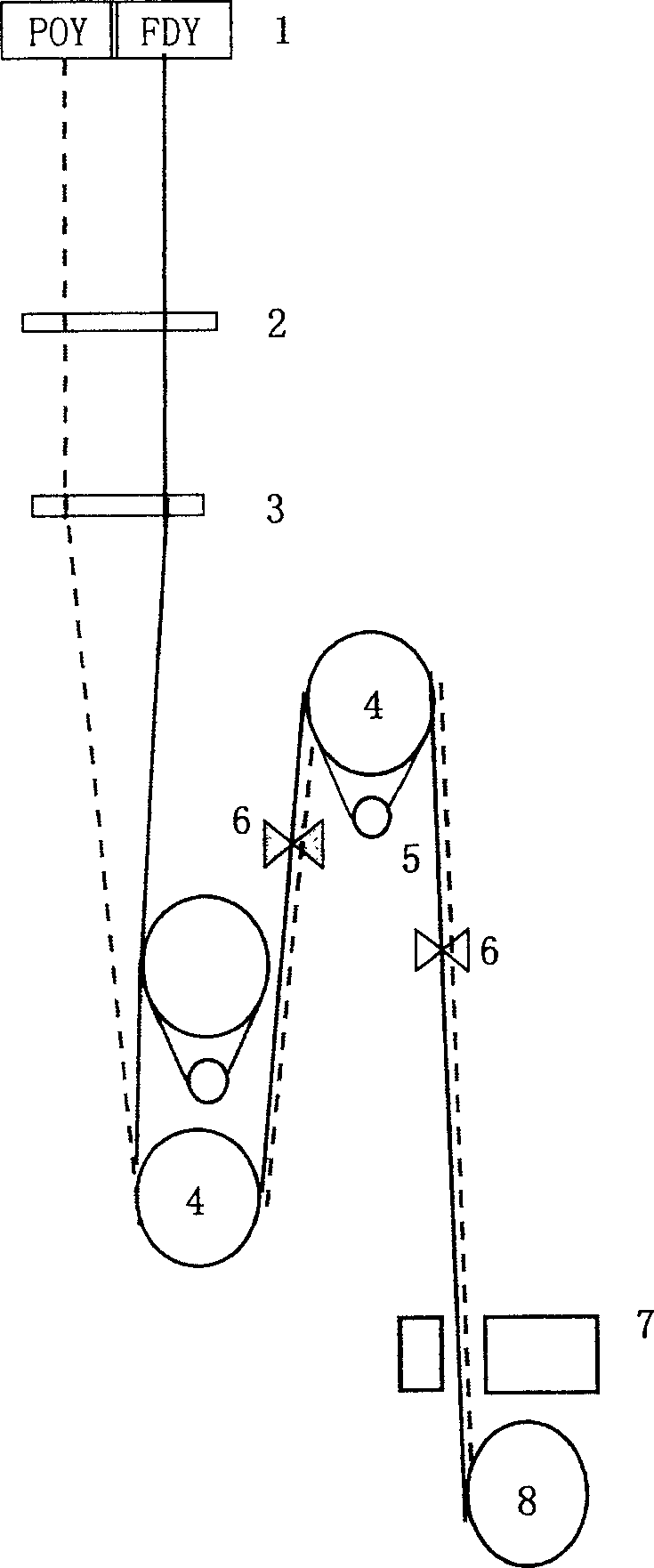

[0019] Such as figure 2 , image 3 Shown, the inventive method comprises the following steps:

[0020] a. Spinning: Melt POY and FDY polyester melts onto POY and FDY spinneret 1 respectively, and simultaneously pull out POY and FDY filaments from the spinneret through POY and FDY silk paths respectively; where POY filaments are sprayed The spinneret positions on the spinneret are in one-to-one correspondence with the spinneret positions on the FDY spinneret. The initial temperature is 270-310°C.

[0021] b. Filament paralleling: the POY filaments and FDY filaments pulled out in step a respectively go through the oiling rack 2 and the oiling agent equalizer 3 for oiling and oiling agent equalization treatment, and then directly merge, and then pass through two stretching rollers 4 and two The network device 6 is paralleled, and the network device is arranged between the stretching roll and the stretching roll and between the stretching roll and the winder; the separating ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com