Process of activating carbon nanotube of great specific surface area

A high specific surface area, carbon nanotube technology, applied in the field of nanomaterials, can solve the problems of immature activation technology and not obvious activation effect, and achieve the effect of being suitable for mass production, low gas price and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] KOH and carbon nanotubes were first mixed directly by physical and mechanical methods at a mass ratio of 5:1, and then dried. The activation reaction is carried out in a horizontal quartz tube furnace. Under the protection of nitrogen gas, the temperature is raised to 700°C, the heating rate is 15°C / min, the flow rate of argon gas is adjusted to 80l / h, and the reaction time lasts for 0.5 hours. After the reaction was completed, the collected product was reacted in dilute HCl (concentration: 0.5M) solution for 1 hour, then washed and dried with deionized water, filtered and dried to obtain a purified product. The product is an activated multi-walled carbon nanotube with a large number of micropores and other defects, and the specific surface area is 480m 2 / g, the pore volume is 0.8cm 3 / g.

Embodiment 2

[0017] KOH and carbon nanotubes were first mixed directly by physical and mechanical methods at a mass ratio of 4:1, and then dried. The activation reaction is carried out in a horizontal quartz tube furnace. Under the protection of argon gas, the temperature is raised to 800°C, the heating rate is 15°C / min, the flow rate of nitrogen gas is adjusted to 90l / h, and the reaction time lasts for 1 hour. After the reaction was completed, the collected product was reacted in dilute HCl (concentration: 0.5M) solution for 1 hour, then washed and dried with deionized water, filtered and dried to obtain a purified product. The product is an activated multi-walled carbon nanotube with a large number of micropores and other defects, and the specific surface area is 530m 2 / g, the pore volume is 1.06cm 3 / g.

Embodiment 3

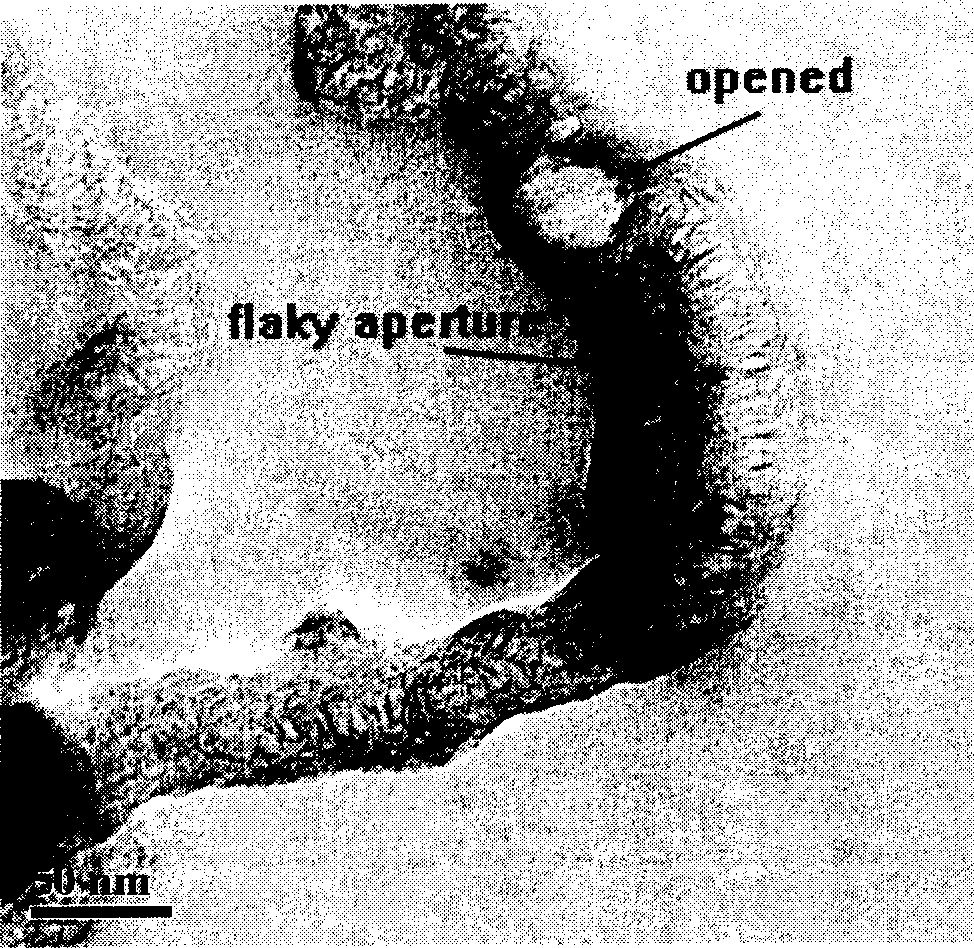

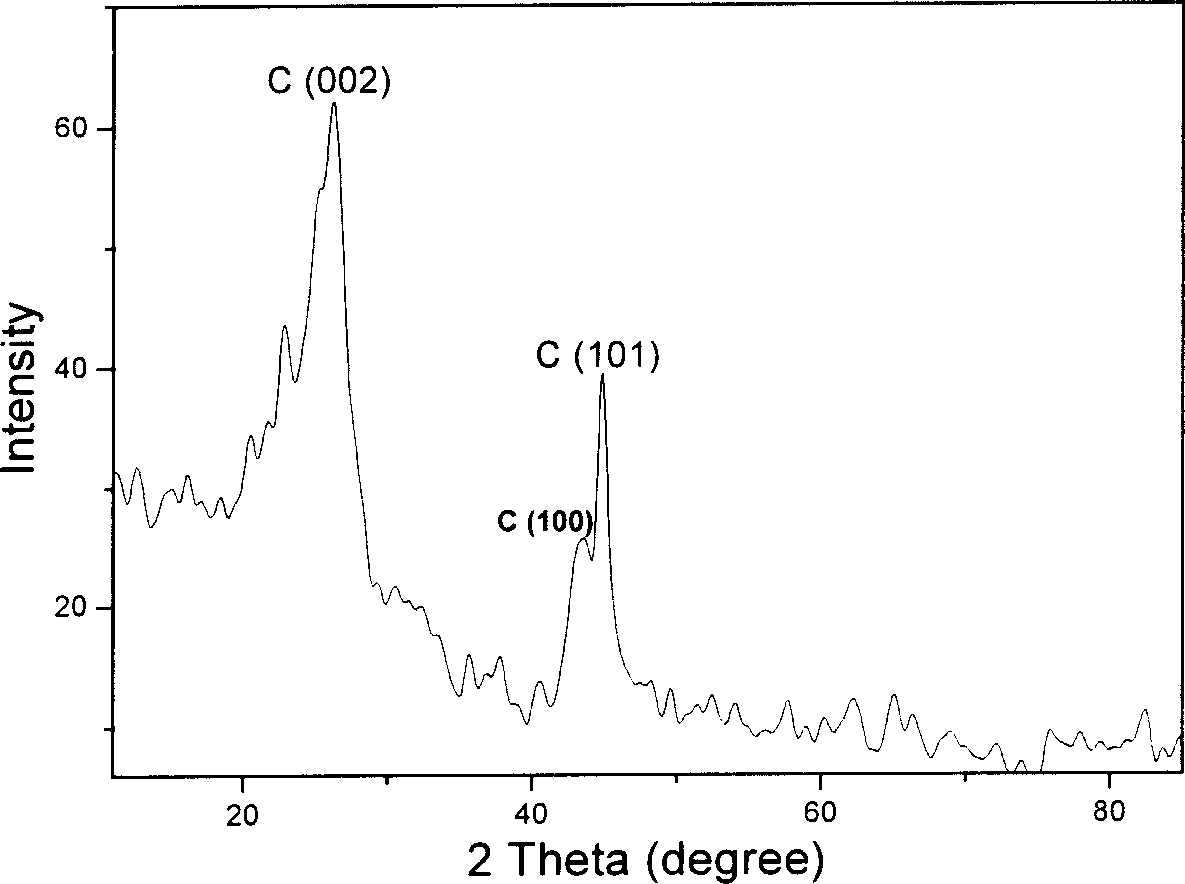

[0019] KOH and carbon nanotubes were first mixed directly by physical and mechanical methods at a mass ratio of 5:1, and then dried. Under the protection of nitrogen, the temperature was raised to 850° C. at a rate of 15° C. / min, the flow rate of nitrogen gas was adjusted to 80 l / h, and the reaction lasted for 1 hour. A large amount of product can be collected in the collector. After the reaction was completed, the collected product was reacted in dilute HCl (concentration: 0.5M) solution for 1 hour, then washed and dried with deionized water, filtered and dried to obtain a purified product. The product is activated crystalline multi-walled carbon nanotubes with a large number of micropores and other defects ( figure 1 and figure 2 ), figure 1 It shows that carbon nanotubes produce a large number of defect structures such as micropores after activation. figure 2 It shows that the carbon nanotubes still retain the graphite crystal structure after activation. After activa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com