Evaporating and cooling system of electric vibration testing bench

A technology of evaporative cooling and electric vibration, which is applied in the cooling of instruments, measuring devices, instruments, etc., can solve the problems of waterway blockage, water leakage, short circuit and leakage, etc., and achieve energy saving, small heat exchange area and reduced leakage the effect of the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

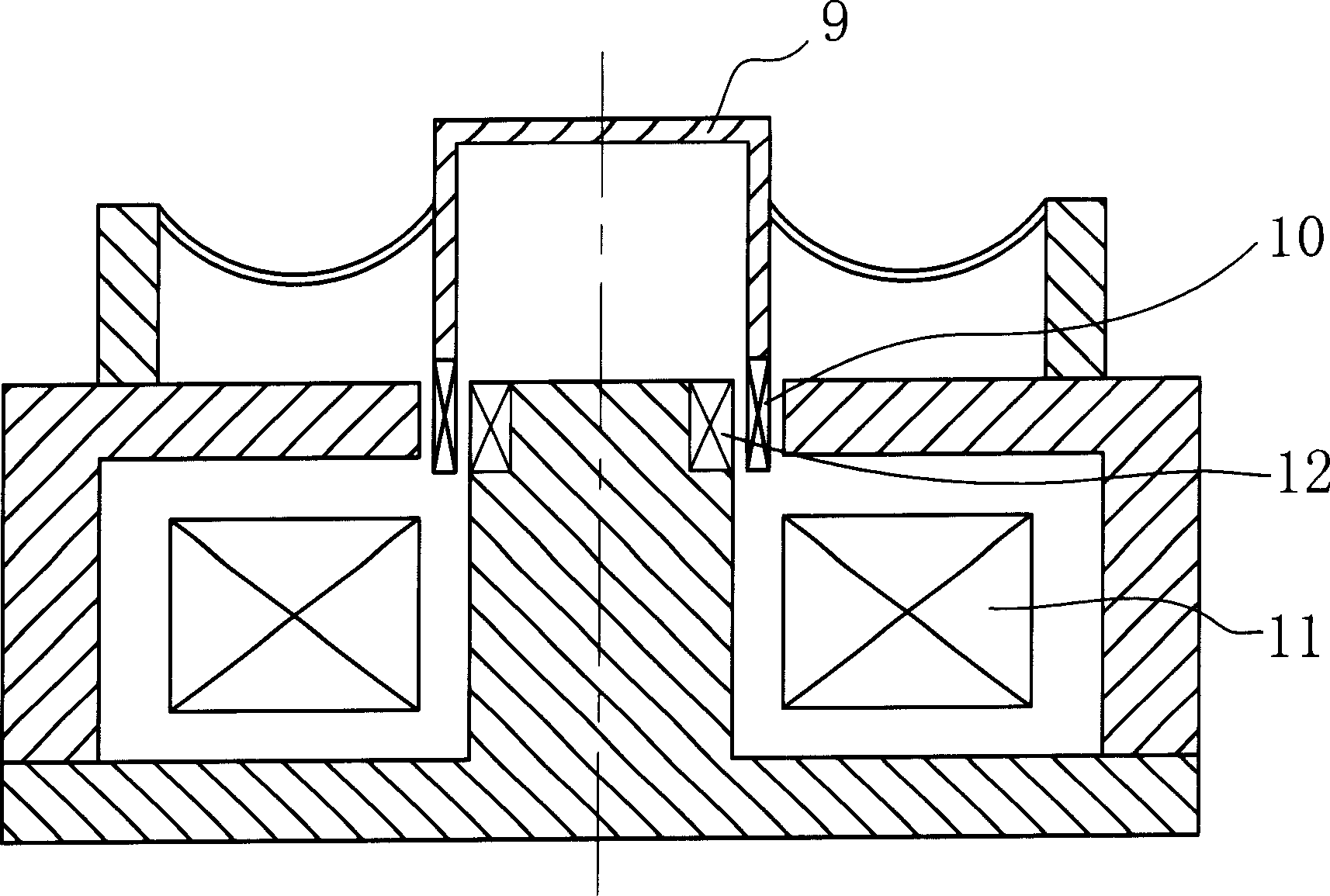

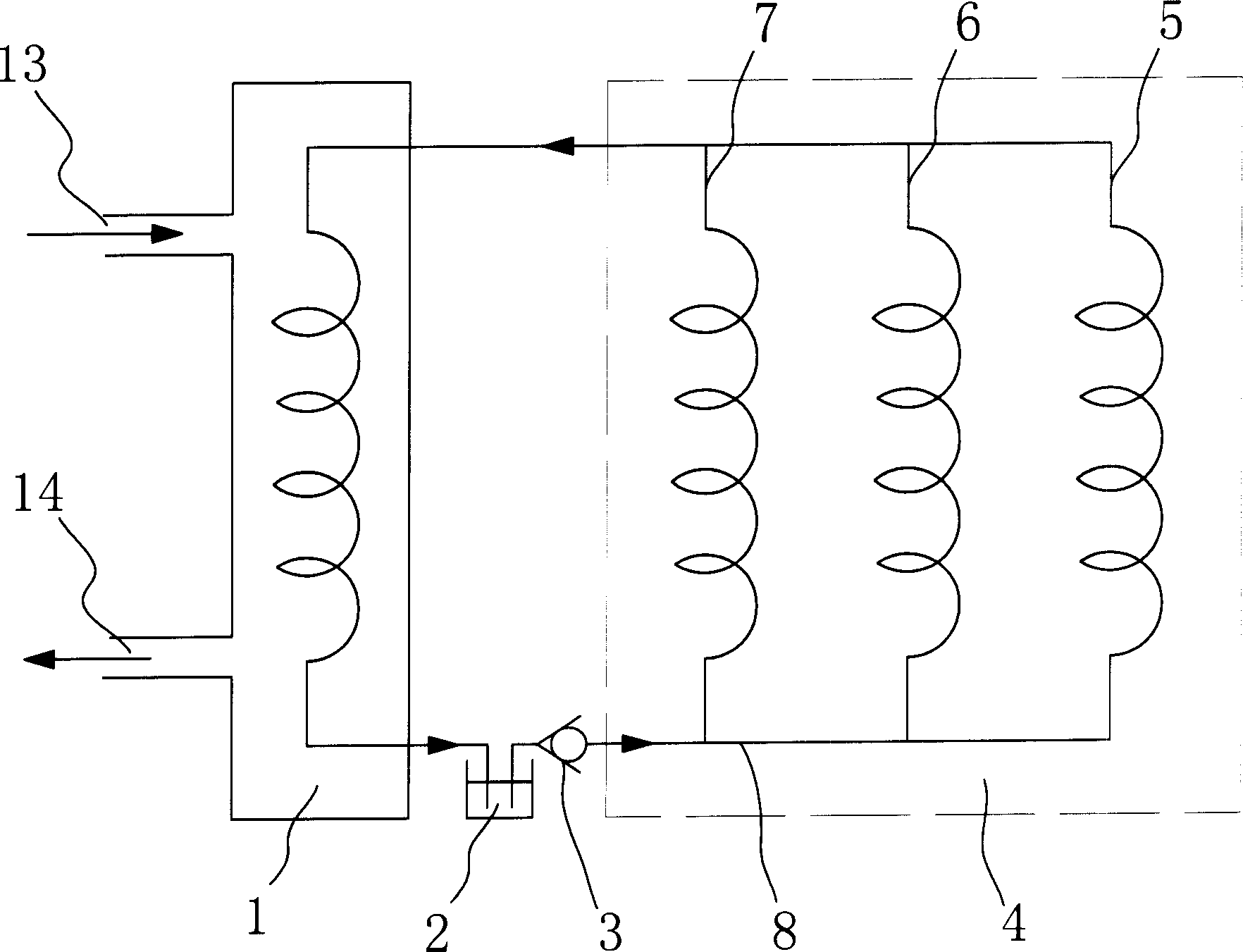

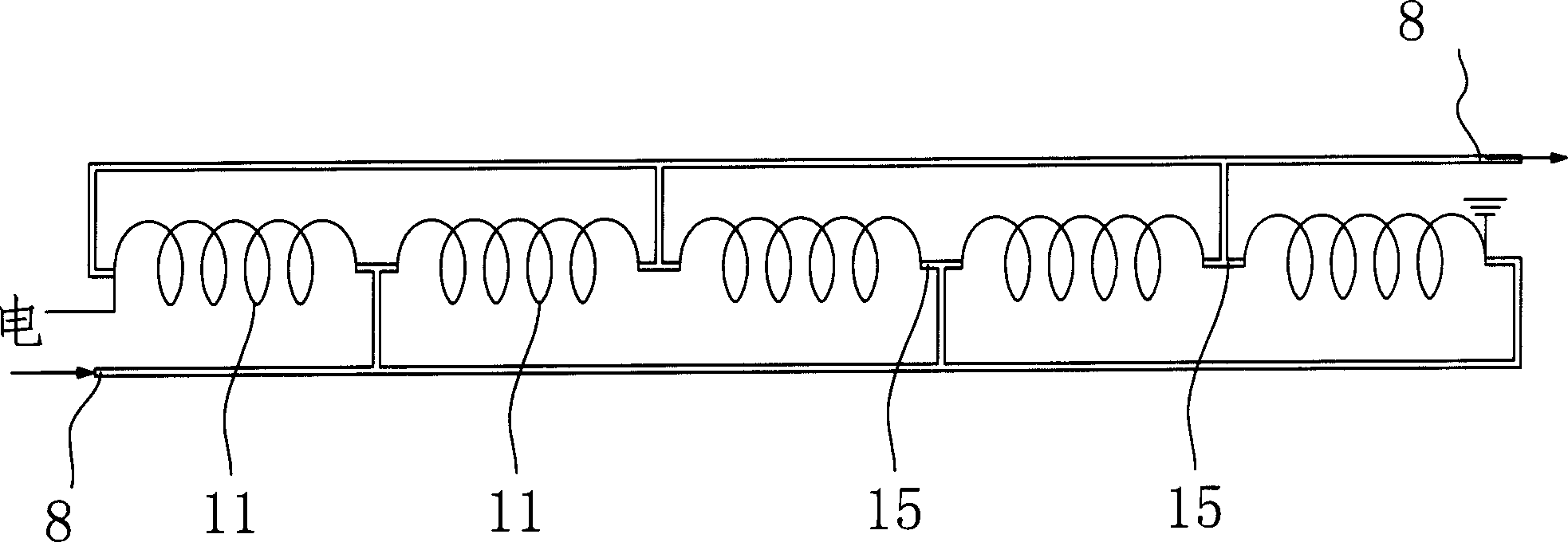

[0051] Embodiment one: see figure 2 As shown, an evaporative cooling system of a large-thrust electrodynamic vibration test bench consists of two parts: a cooling medium 8 and a circulating cooling circuit. The cooling medium is a fluorocarbon compound with a boiling point of 50-60°C, specifically one of R-113, FLA, FF31-A, and FF31L. The circulating cooling circuit is composed of a cooling channel, a heat exchanger 1, a liquid storage tank 2, and a one-way valve 3 in series through pipelines in sequence, wherein the cooling channel is connected in parallel by the excitation coil cooling channel 7, the driving coil cooling channel 6 and the short-circuit ring cooling channel 5 constitute. The drive coil cooling channel 6 is the inner tube of the hollow drive coil, which adopts a single-input and single-out design, such as Figure 4 As shown, the entire hollow drive coil body is used as the coil winding, and the inner tube is used as a cooling channel. The excitation coil c...

Embodiment 2

[0053] Embodiment two: see Figure 5 As shown, an evaporative cooling system of a large-thrust electrodynamic vibration test bench consists of two parts: a cooling medium 8 and a circulating cooling circuit. The difference from the first embodiment is that the cooling channel of the excitation coil adopts the immersion design (suitable for very high-power electric platforms, F>30T). The immersion design is to seal the excitation coil 11 of the electric table in a common coil form in a cavity filled with a cooling medium 8, such as Image 6 As shown, that is, the excitation coil 11 is immersed in a closed cavity 16 as a whole, and the closed cavity 16 serves as a cooling channel. In addition, an interlayer is arranged on the periphery of the airtight cavity 16, and cooling water is passed through the interlayer to improve the cooling effect. This structure can be applied to extra-large electric vibrating tables (for example, thrust F>40T), and the key is to keep the working p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com