Motorcycle engine cylinder

A technology for engines and motorcycles, which is applied in the field of cylinders of combustion engines, which can solve the problems of difficult processing, scrapped cylinders, and high maintenance costs, and achieve the effects of simple structure, guaranteed sealing, and increased inflation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

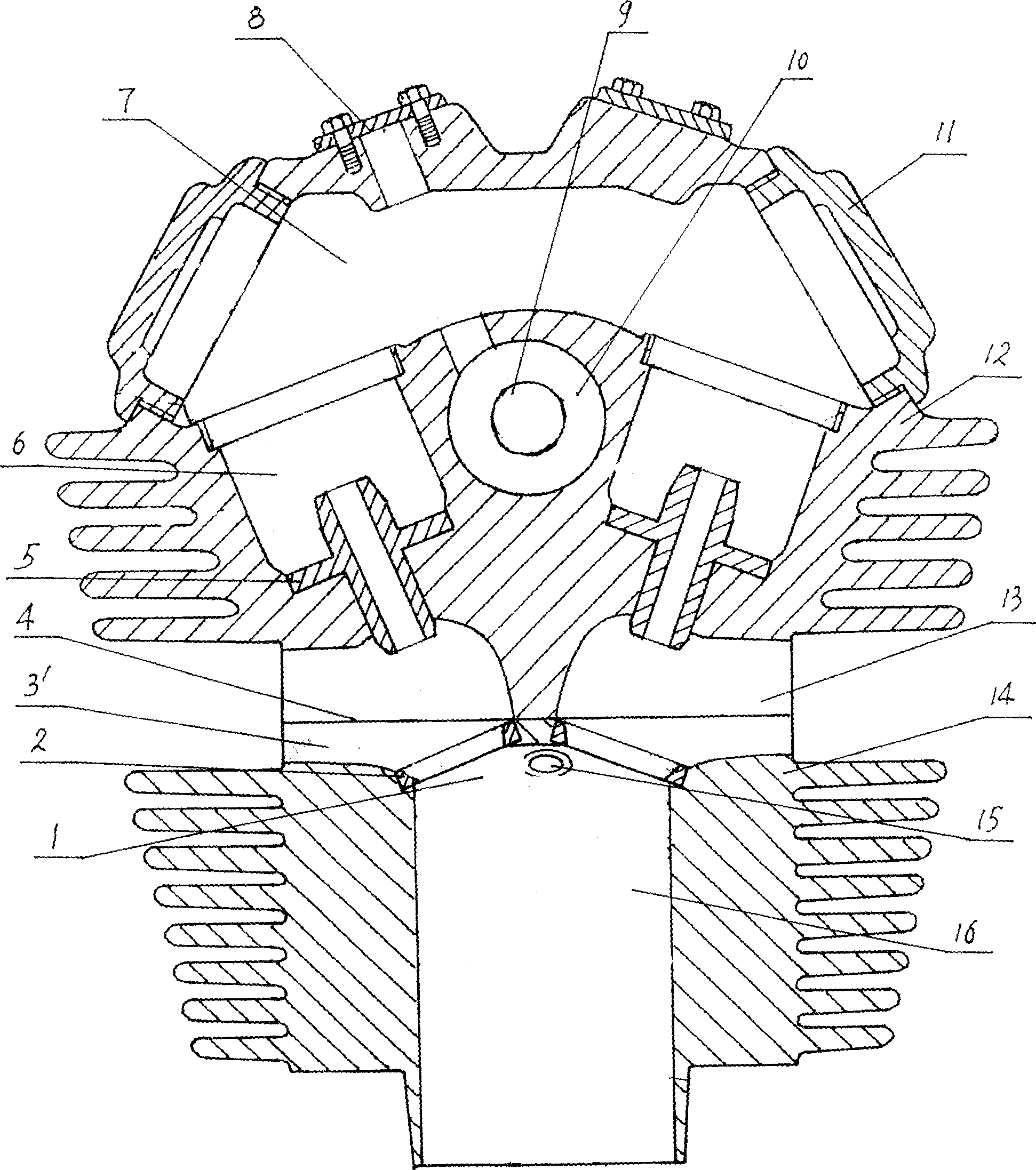

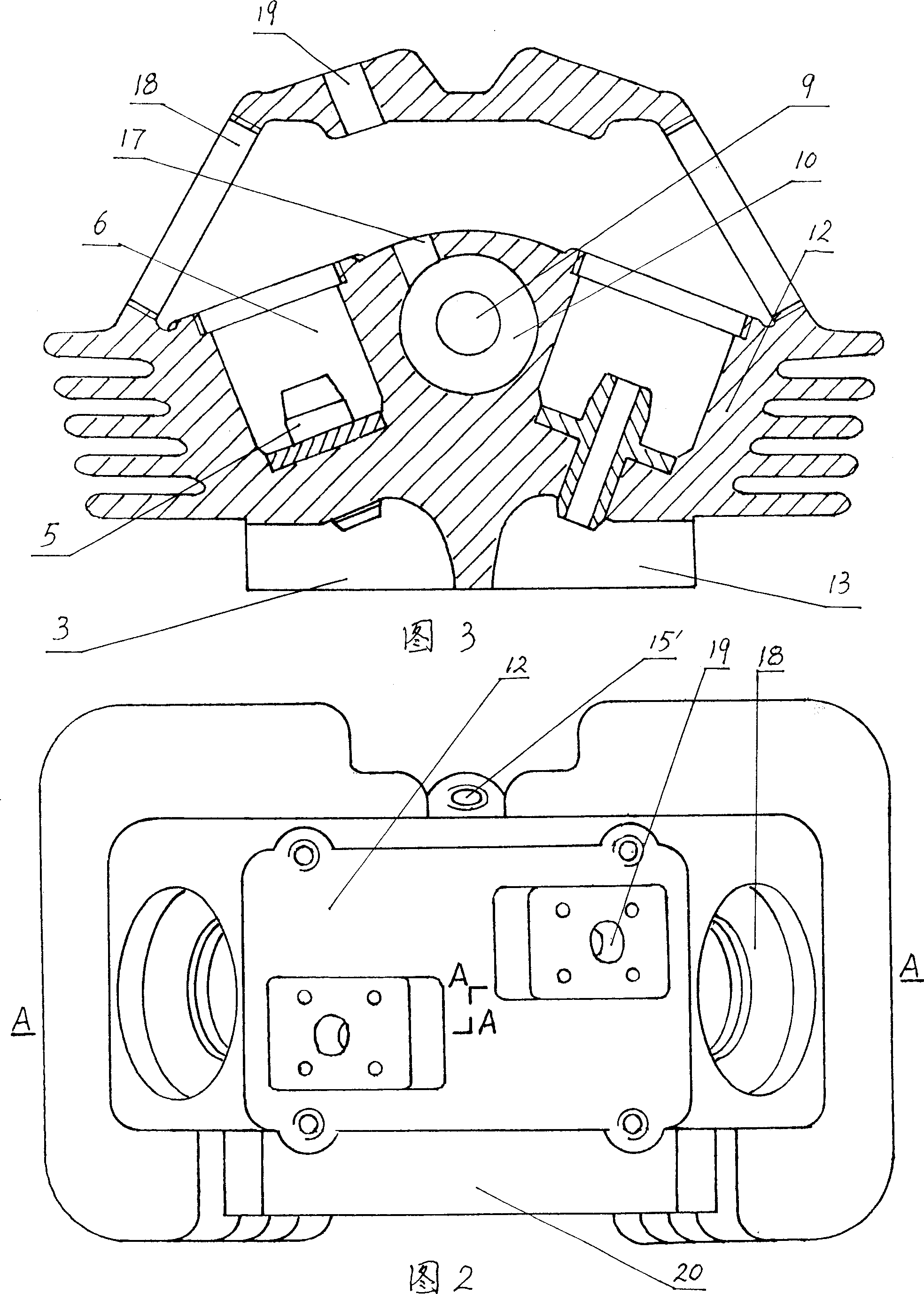

[0016] See Figure 1 to Figure 4 , The cylinder head 12 of this embodiment adopts an upper camshaft type. One end of the cylinder head 12 is provided with a sprocket chamber 20, and the other end is provided with a spark plug hole 15'. The upper part of the cylinder head is provided with a cavity 7 for installing a valve lifting device. A cam chamber 10 is provided between the cavity 7 and the valve holes 6 of the intake and exhaust passages. The two ends of the cam chamber are provided with One of the holes 9 supporting the camshaft communicates with the sprocket chamber 20; the cavity 7 communicates with the cam chamber 10 through the lower guide hole 17, and the upper end of the cylinder head 12 is provided with an upper guide hole 19 corresponding to the lower guide hole. The guide hole 19 is covered with a cover plate 8; the walls on both sides of the cavity 7 are provided with valve adjusting holes 18 and covered with a cover 11. The cylinder head 12 and the cylinder block 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com