Method of making cell growth surface

A growth surface and cell technology, which is applied in the growth surface, cell culture structure and manufacturing fields, can solve the problem of low cell density, porous algin carrier mechanism strength, etc., to increase mechanical strength, promote cell growth, and increase cell density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

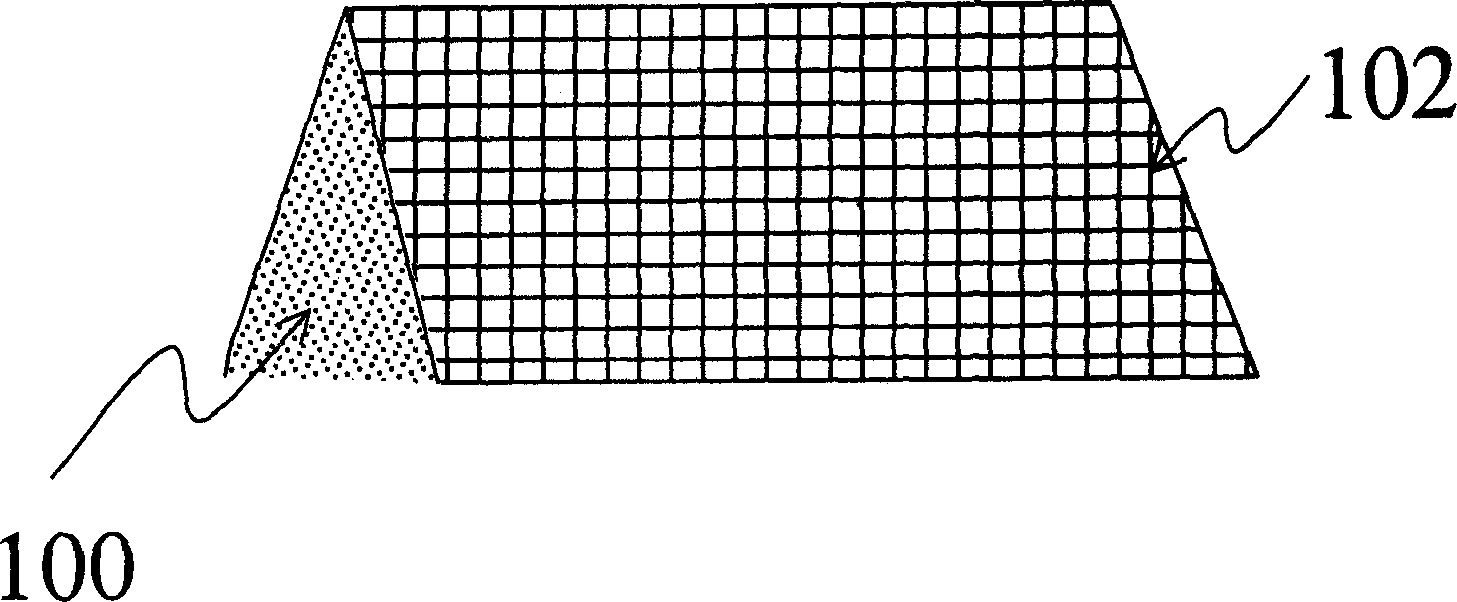

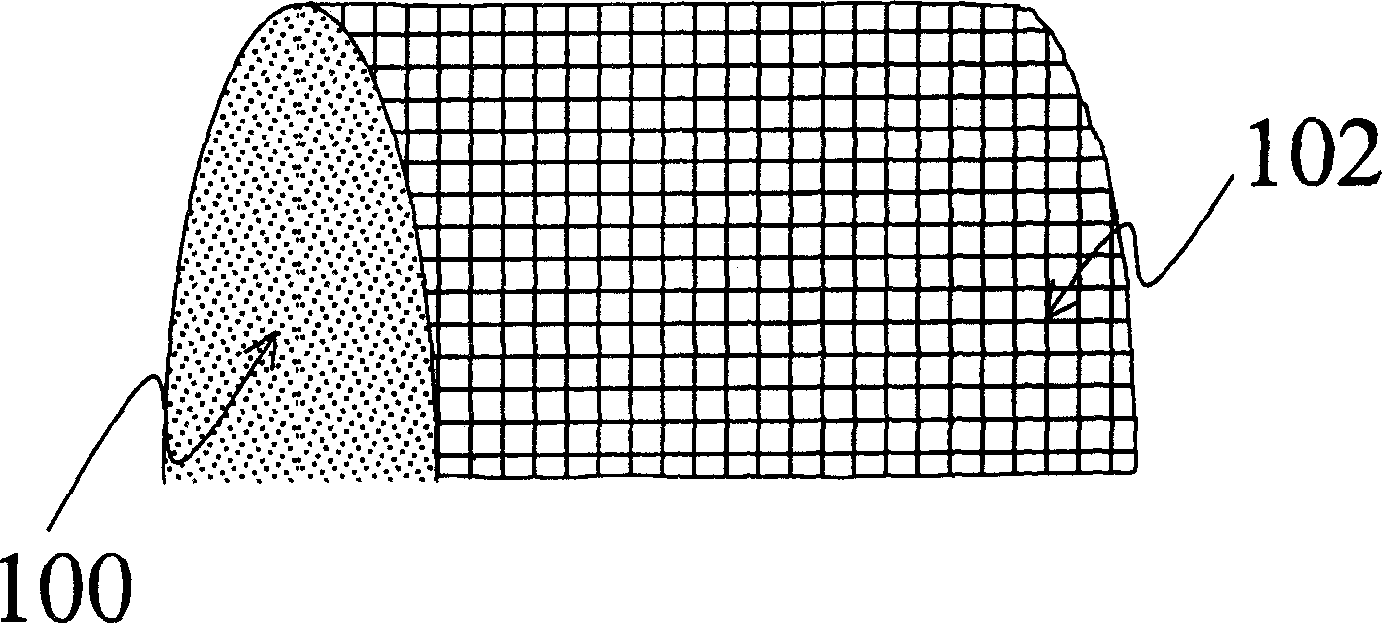

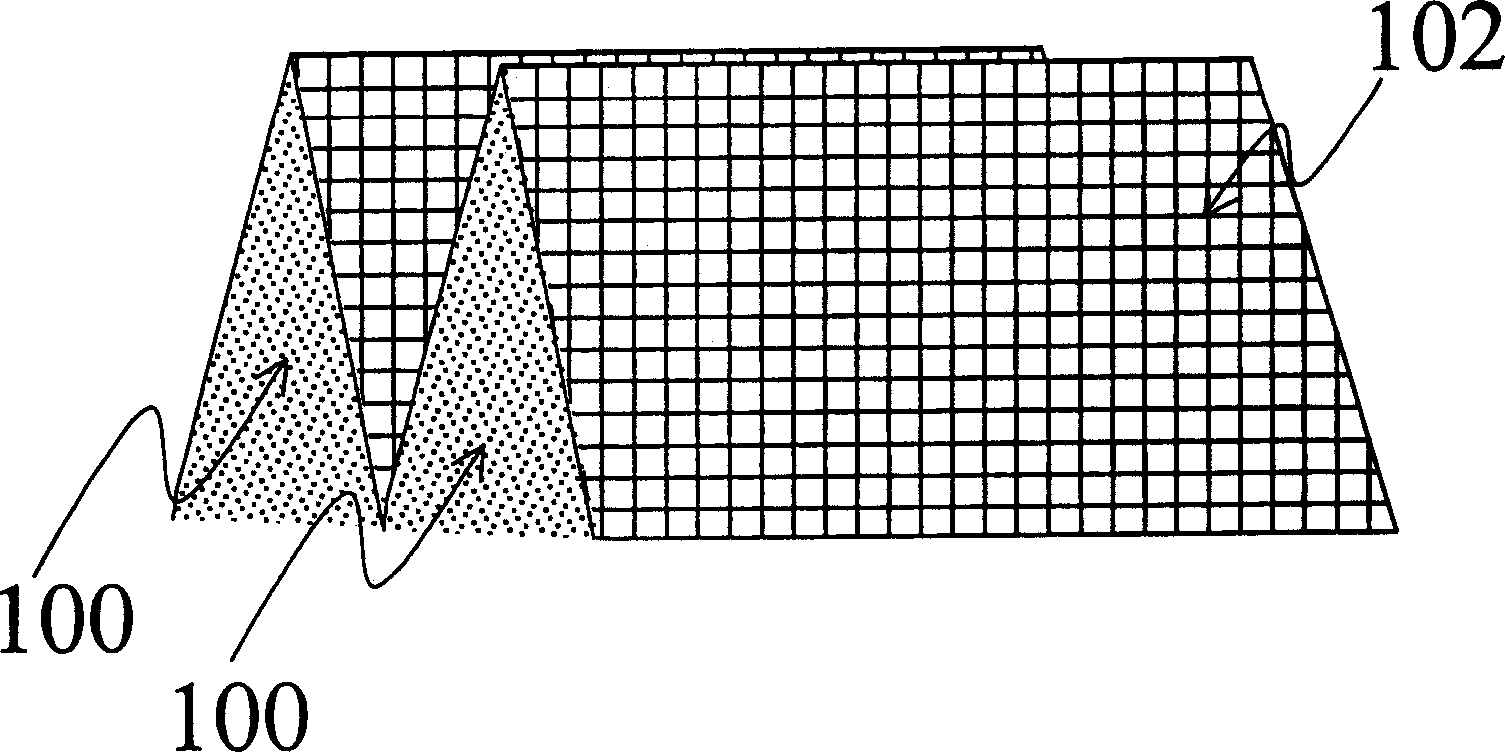

[0071] Example 1: Preparation of Porous Growth Surface

[0072] This example describes the preparation method of the porous structure of the present invention. The porous structure is modified as a scaffold to physically support the growth of living cells. The materials and methods are as follows: general stores purchase polypropylene netting with a mesh size of 1m / m×1m / m (PolyPropylene Netting). Alinic acid (or alginate) was purchased from FMC BioPloymer (Philadelphia, PA 19103, USA). Calcium chloride was purchased from Sigma-Aldrich (www.sigmaaldrich.com). The polypropylene mesh was cut into 10 cm long and 3 cm wide, folded and fused and heated to form a 3D (ellipse) shaped cylinder with a width of 1 cm and a height of 3 mm. Alginic acid powder was dissolved in deionized water to form a 2% w / v alginic acid solution. Place () shaped cylindrical polypropylene mesh in a tank, inject alginic acid solution into the groove where () shaped cylindrical polypropylene mesh is place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com