Organic red luminescent material for white light LED packaging

A technology of LED encapsulation and red fluorescence, which is applied in the field of preparation of organic red fluorescent materials and materials, and can solve the problems of affecting the luminous efficacy of devices, demanding aging performance of packaging materials, and low light conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Take by weighing 8.96 grams of dibenzoylmethane, be dissolved in 100ml of acetone, be defined as solution A, and take by weighing rare earth nitrate Eu(NO 3 ) 3 3.38 grams, dissolved in 20ml of deionized water, designated as solution B, heated solution A to 50°C, and added solution B dropwise to A under the stirring condition of 100 rpm, and used 0.1 mol / liter of dilute NaOH solution The pH value of the system was adjusted to 6.5, and the reaction was continued for 1 hour while maintaining the temperature and stirring, and a light yellow precipitate was obtained. Filter the precipitate, wash with ethanol and water three times respectively, and dry in a vacuum oven at 60°C for 20 hours to obtain the finished product.

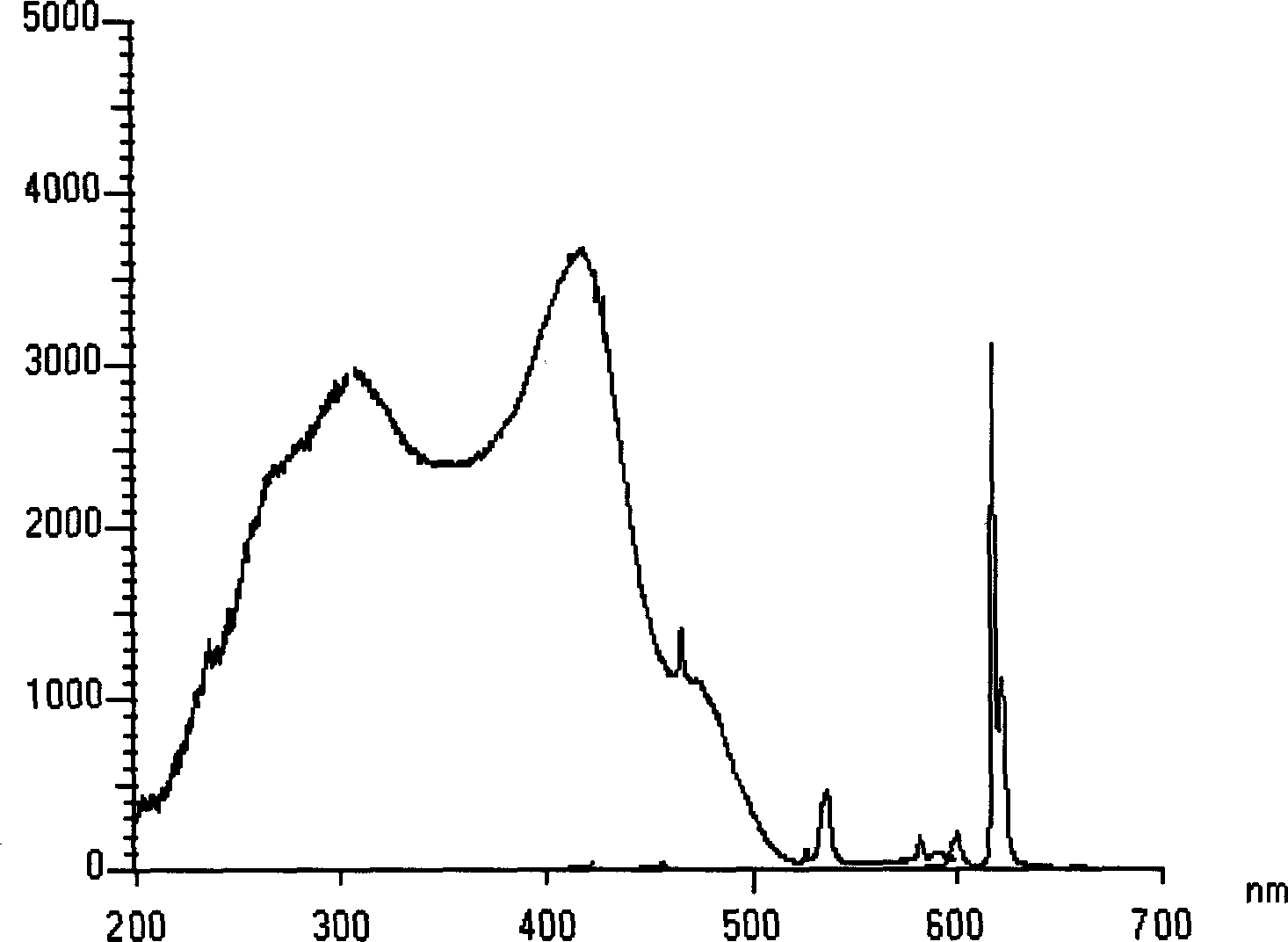

[0043]Its absorption and emission spectra are shown in the appendix figure 1 .

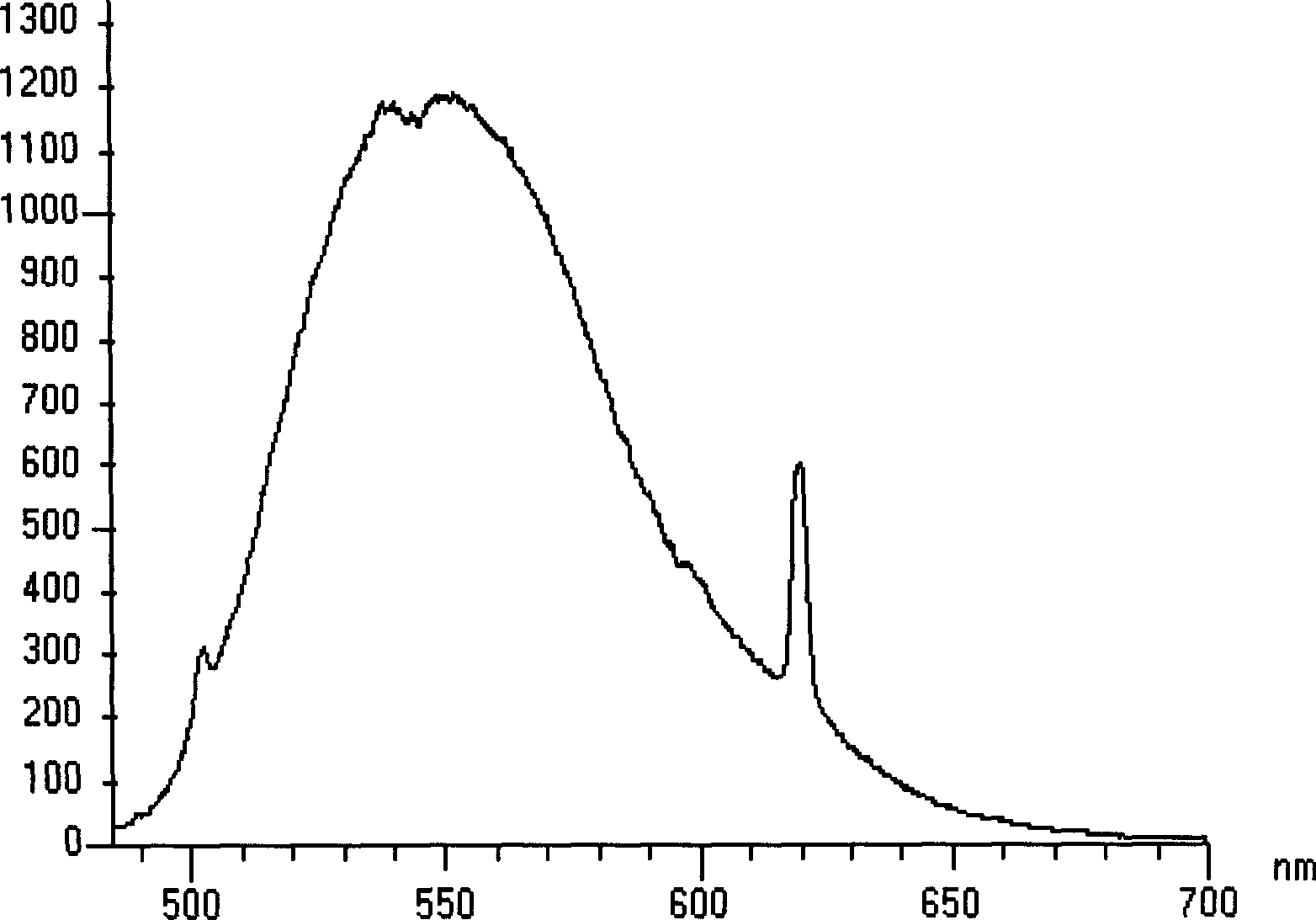

[0044] The spectrum of the compound described in Example 1 and YAG powder mixed by 1:1 under the excitation of blue light at 465nm is shown in the appendix figure 2 .

example 2

[0046] Take by weighing 6.73 grams of dibenzoylmethane, dissolve it in 100ml of acetone, and set it as solution A, take by weighing 7.07 grams of triisooctylamine, dissolve it in 100ml of ethanol, set it as solution B, and take by weighing rare earth nitrate Eu(NO 3 ) 3 3.38 grams, dissolved in 20ml of deionized water, defined as solution C, mixed solutions A and B, heated to 60°C, and added solution C dropwise to the mixed solution of A and B under the condition of 300 rpm, and used The pH value of the system was adjusted to 7.0 with 0.1 mol / L dilute NaOH solution, and the reaction was continued for 6 hours while maintaining the temperature and stirring, and a light yellow precipitate was obtained. Filter the precipitate, wash with ethanol, acetone, and water three times, and dry in a vacuum oven at 40°C for 24 hours to obtain the finished product.

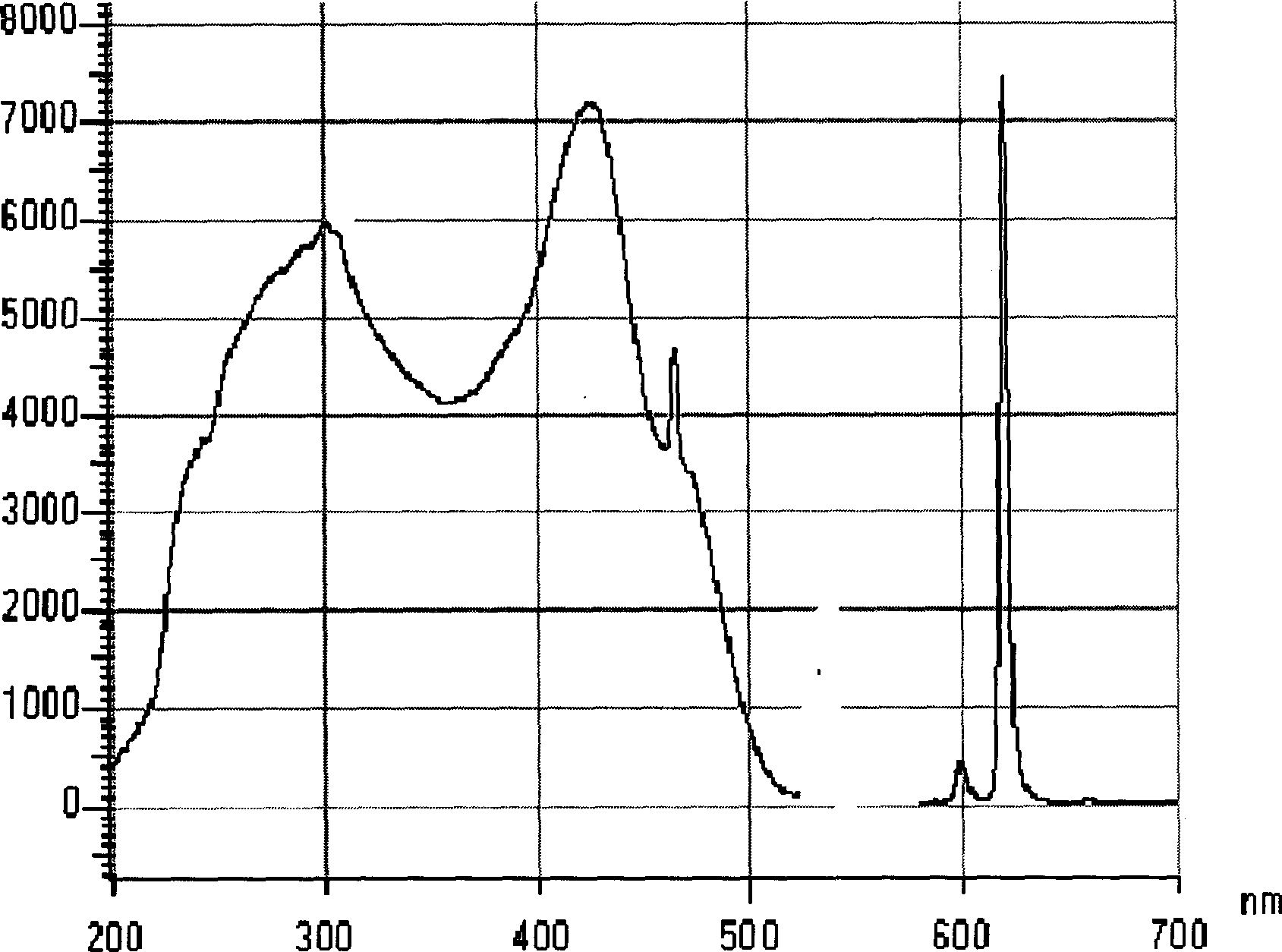

[0047] Its absorption and emission spectra are shown in the appendix image 3 .

[0048] The spectrum of the compound descri...

example 3

[0050] Take by weighing 6.70 grams of α-thiophene trifluoroformyl acetone, dissolve it in 100 ml of ethanol, and call it solution A; weigh 1.98 grams of 1,10-phenanthroline, dissolve it in 50 ml of ethanol, and call it solution B, call it Take rare earth nitrate Eu(NO 3 ) 3 3.38 grams, dissolved in 20ml of deionized water, defined as solution C, mixed solutions A and B, heated to 60°C, and added solution C dropwise into the mixed solution of A and B under the condition of 200 rpm, and used The pH value of the system was adjusted to 5.5 with 0.1 mol / L dilute NaOH solution, and the reaction was continued for 4 hours while maintaining the temperature and stirring, and a light red precipitate was obtained. Filter the precipitate, wash with ethanol, acetone, and water three times, and dry in a vacuum oven at 80°C for 24 hours to obtain the finished product.

[0051] Its absorption and emission spectra are shown in the appendix Figure 5 .

[0052] The spectrum of the compound d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com