Selvage device

A technology of selvedge and edging, which is applied in the direction of selvage opening mechanism, textile, loom, etc., and can solve the problems of large-scale and complicated control of driving motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

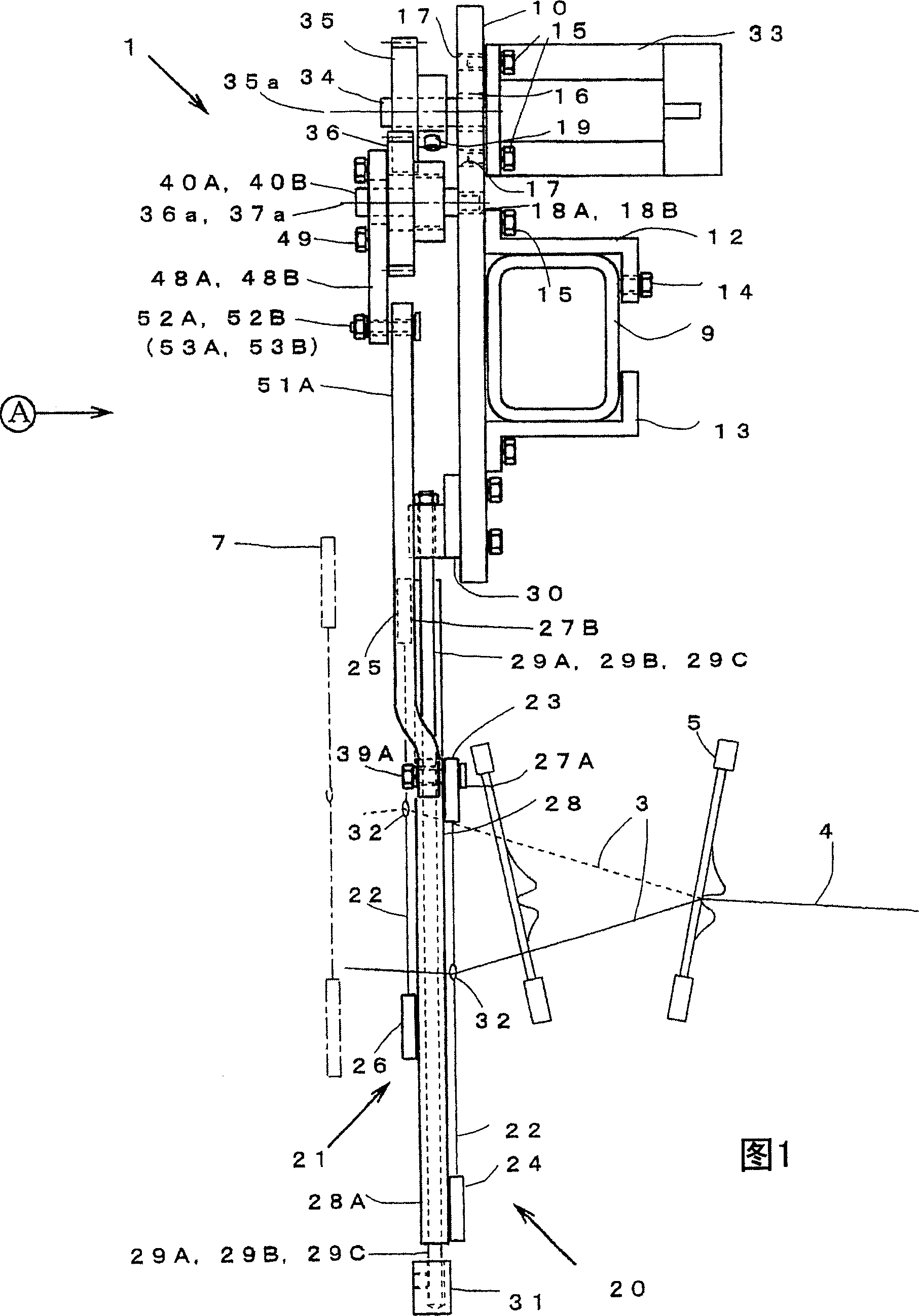

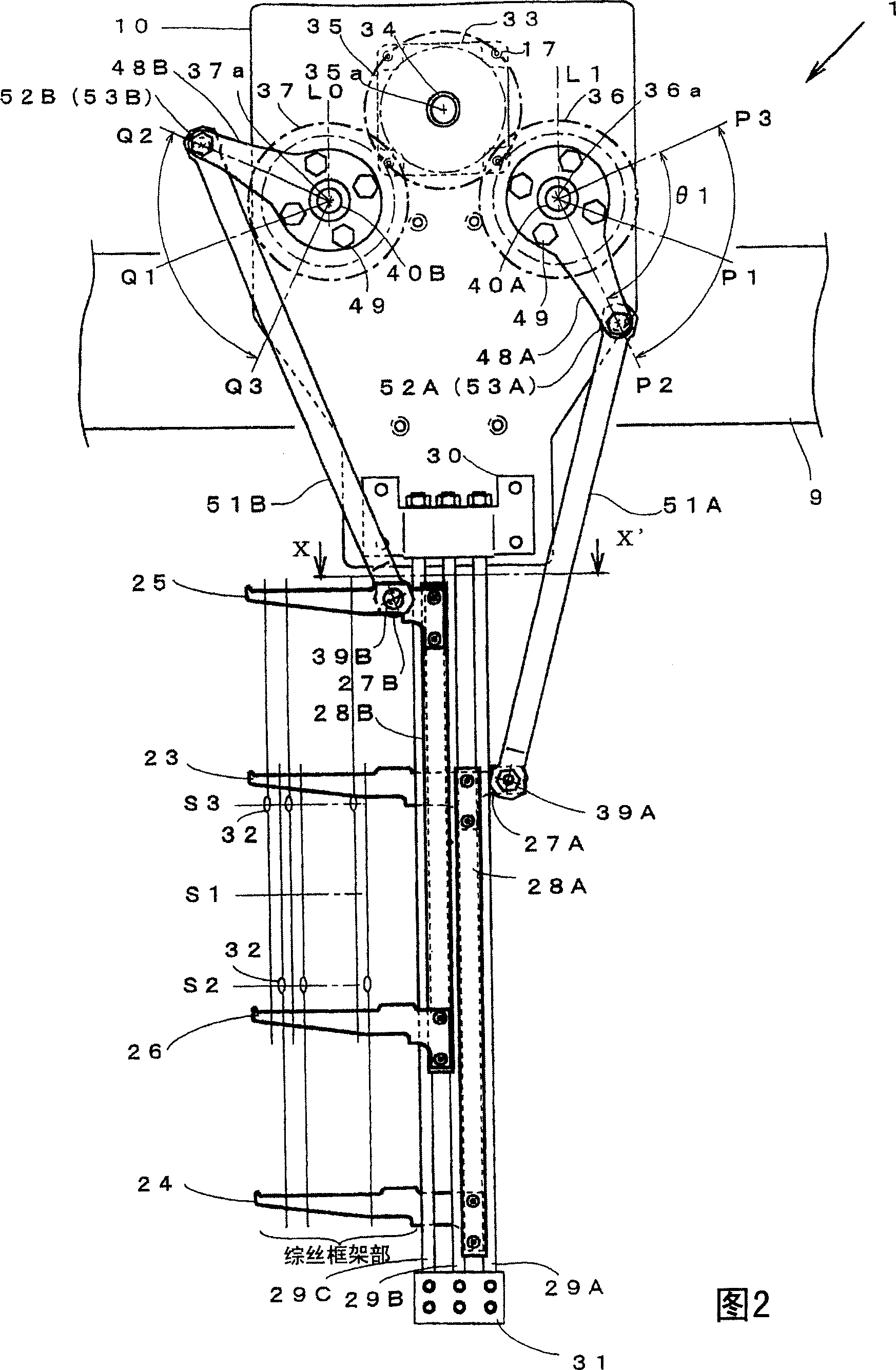

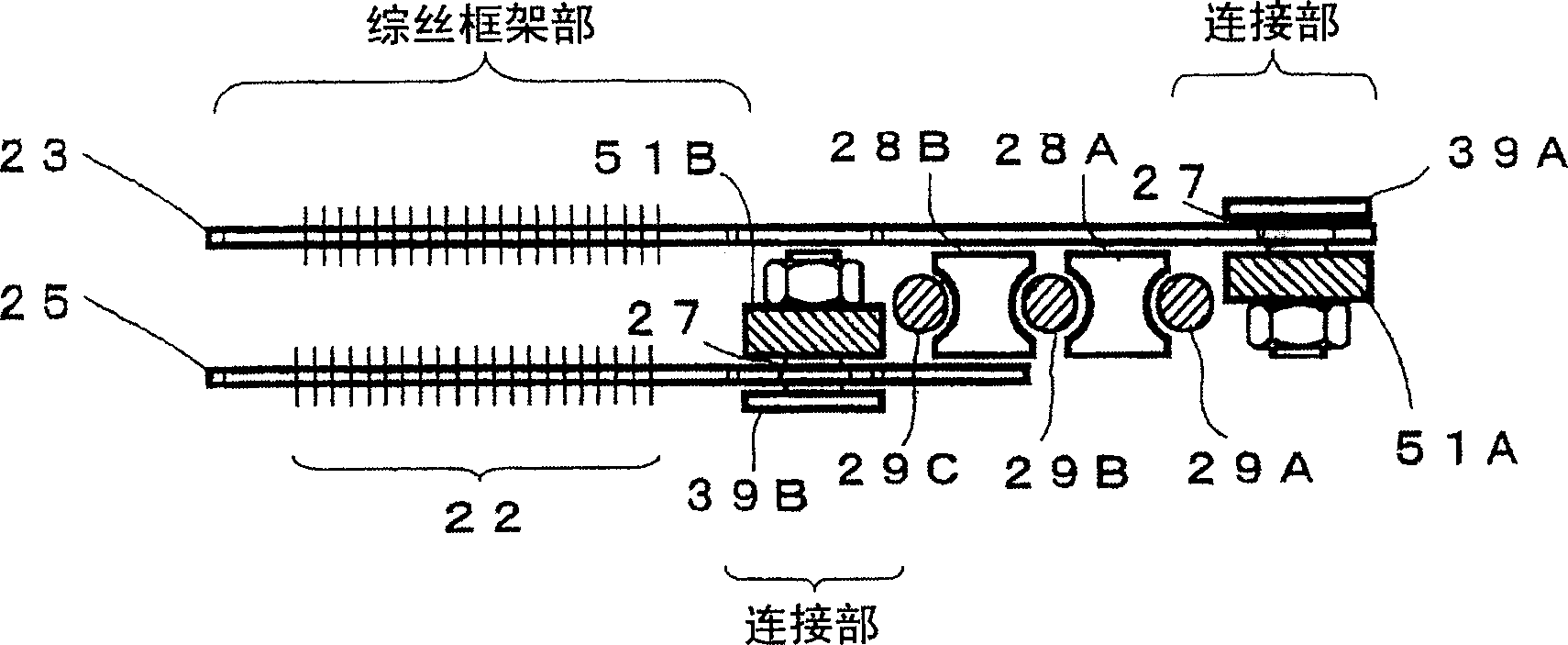

[0035] Hereinafter, specific embodiments of the selvage device for a loom according to the present invention will be described with reference to the accompanying drawings. In Figure 1~ Figure 4 In the figure above, the selvedge device 1 configured on both sides of the end of the fabric 4 to move the edge yarn 3 to open is specifically shown. The edge yarns 3, 3 are drawn out through the edge yarn bobbins, tensioners and guides, etc., which are not shown in the figure and arranged on the loom, and their front ends pass through the yarn guides 32, 32 constituting the selvage device 1 of the present invention, and then Through the reed 5 to the cloth fell and connected to the fabric 4 . In addition, in the illustration, the example of the selvedge device arranged on the right side is shown from the loom front, but the selvage device 1 not shown in figure which is bilaterally symmetrical is arrange|positioned similarly on the left side, for example.

[0036] Roughly speaking, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com