Vibration finishing machine with drying function

A technology of drying function and finishing machine, which is applied in the directions of drying solid materials, heating to dry solid materials, and drying. It can solve the problems of workpiece surface influence, workpiece impact, and small capacity, etc., and achieve continuous drying and batch drying. Reduce heat loss and ensure processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

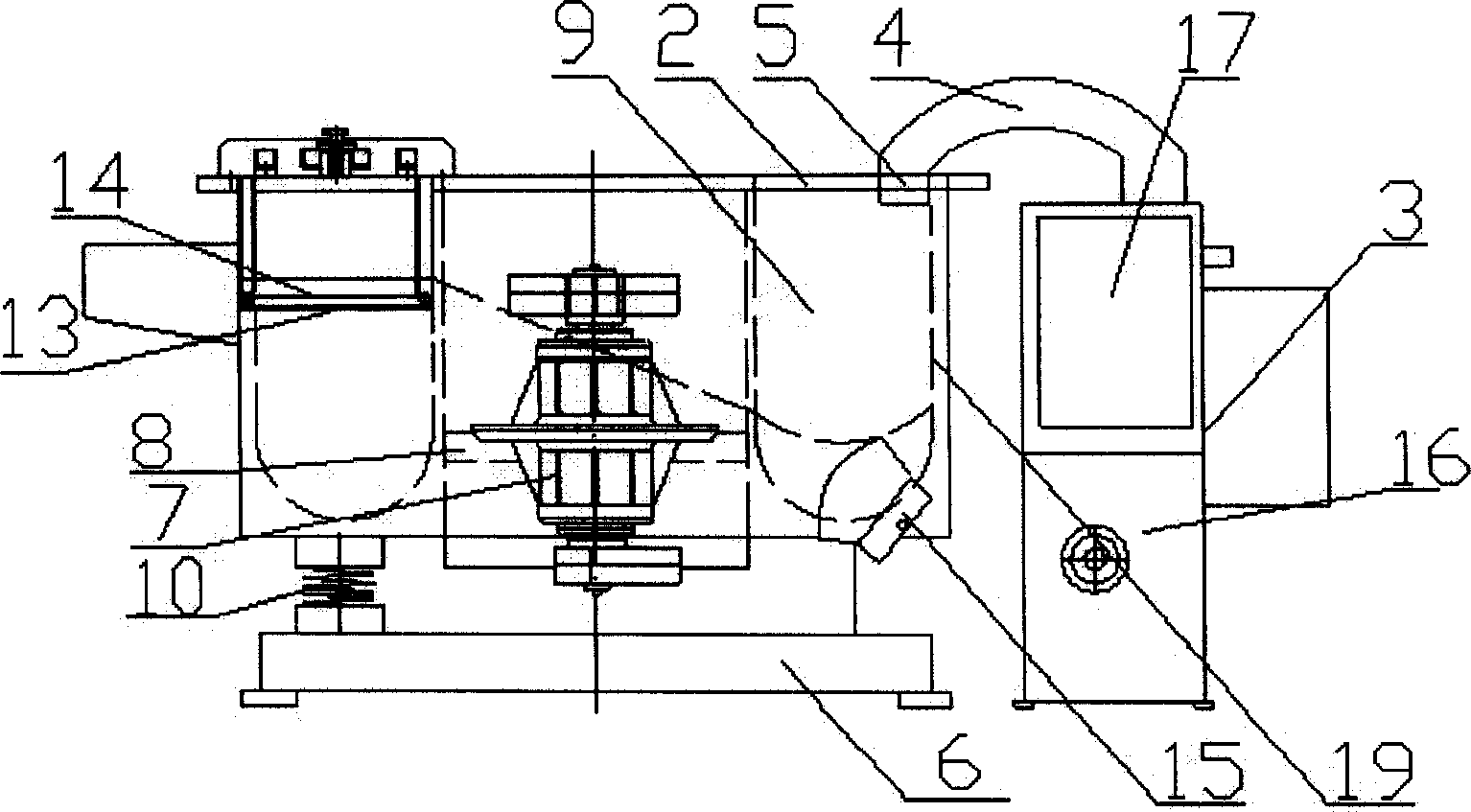

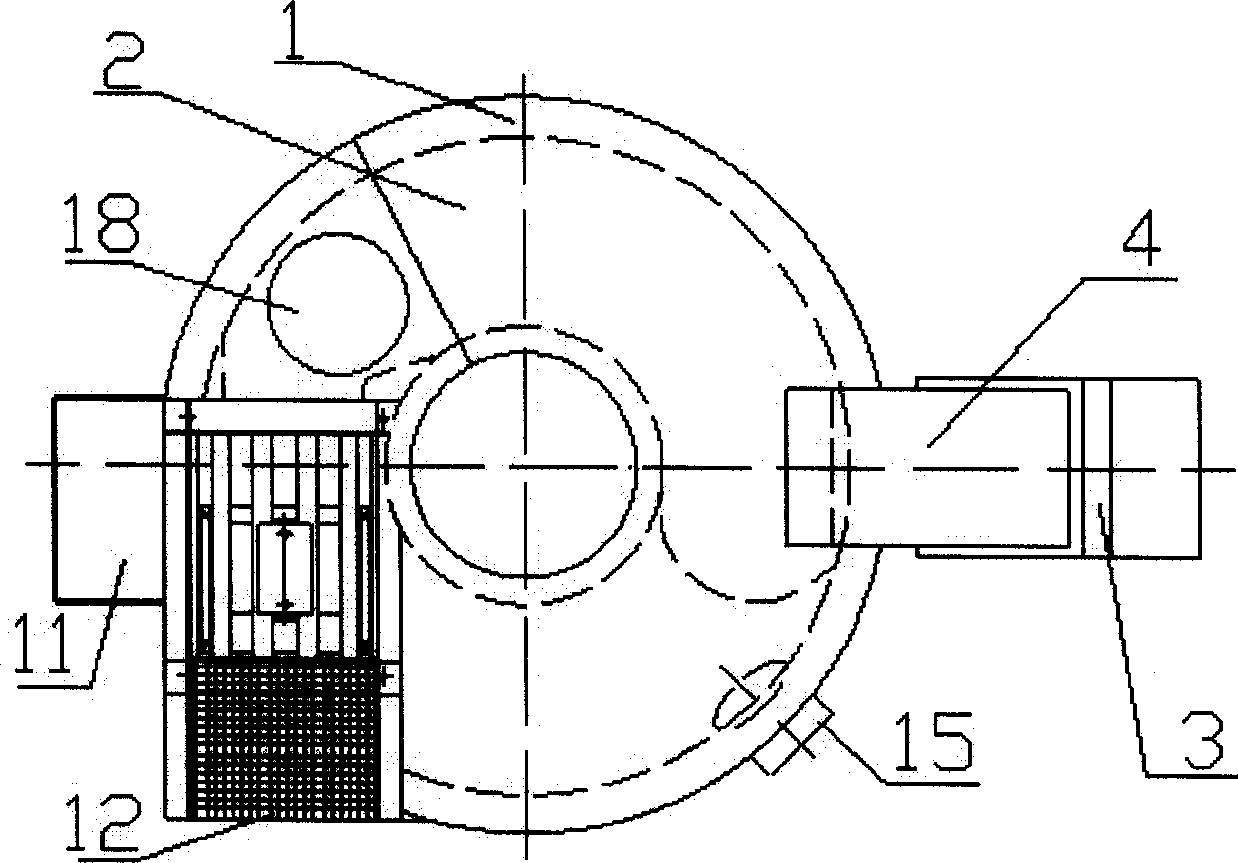

[0013] Embodiment of the present invention: make a vibrating machine (1) earlier, the structure of vibrating machine (1) comprises base (6), installs an annular groove type container (9) by spring (10) on base (6), container (9) vibrating motor (7) and motor mounting flange (8) are installed in the middle, workpiece inlet (11) and workpiece outlet (12) are made on container (9), workpiece outlet (12) in container (9) ) position to install a fixed sieve plate (13) and a movable sieve plate (14) to realize automatic sorting of workpieces; a discharge port (15) is provided on the side of the container (9). The vibrator (1) is provided with a cover plate (2), and the cover plate (2) is provided with an air inlet (5), and the air inlet (5) can be provided with 1 or 1 according to the size of the container (9). More than one, to ensure the uniformity of the drying temperature, a transparent observation window (18) is provided on the cover plate (2), which is convenient for observing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com