Heat exchanger, especially charge-air/coolant radiator

A technology of heat exchanger and charge air, which is applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc., and can solve the problem of unsatisfactory cooling efficiency of charge air/coolant cooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

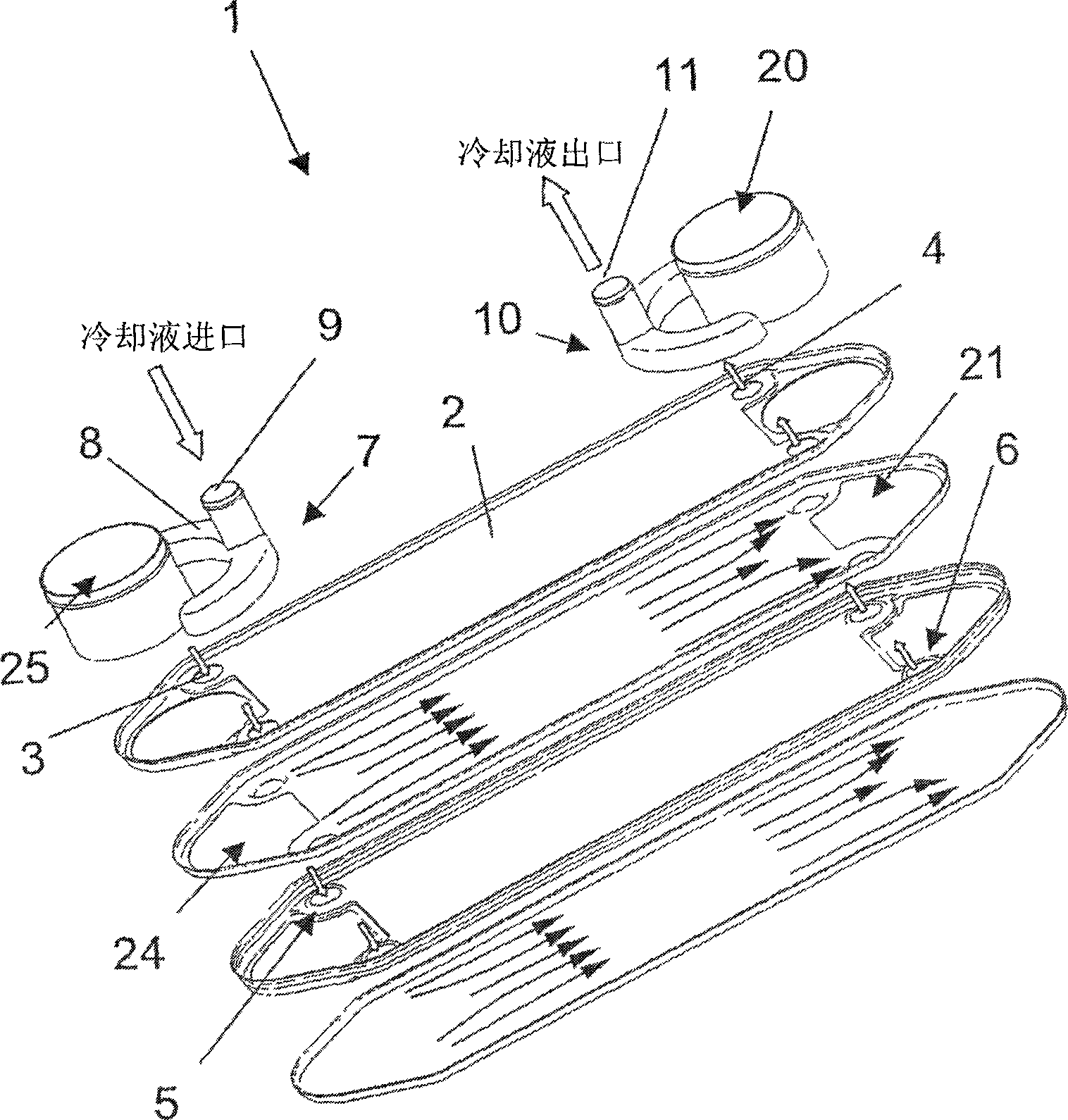

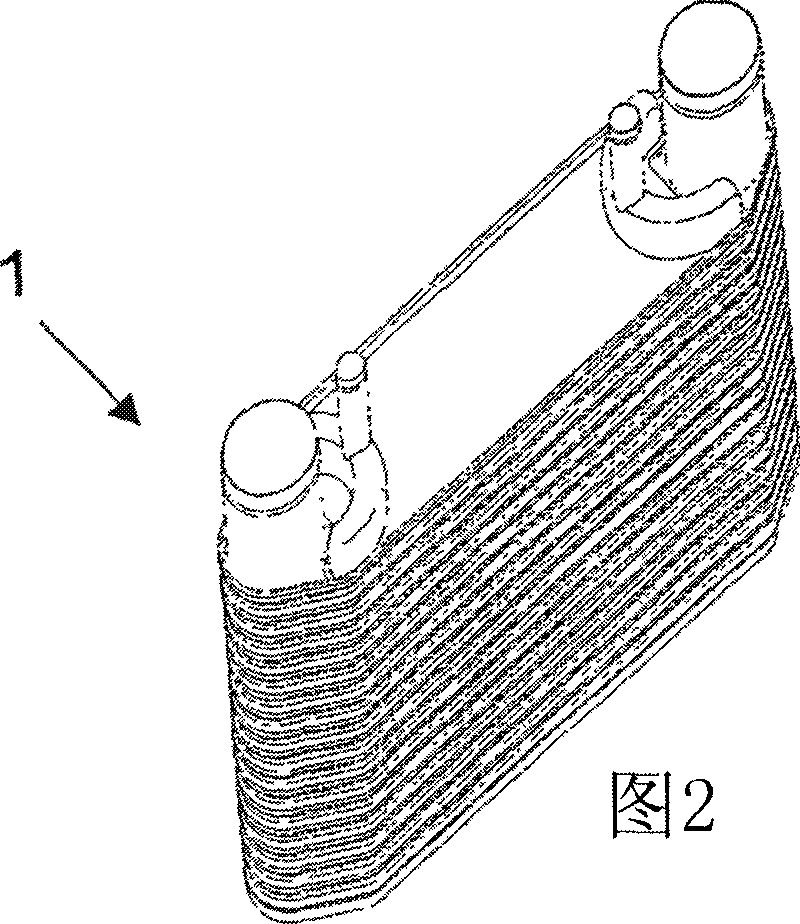

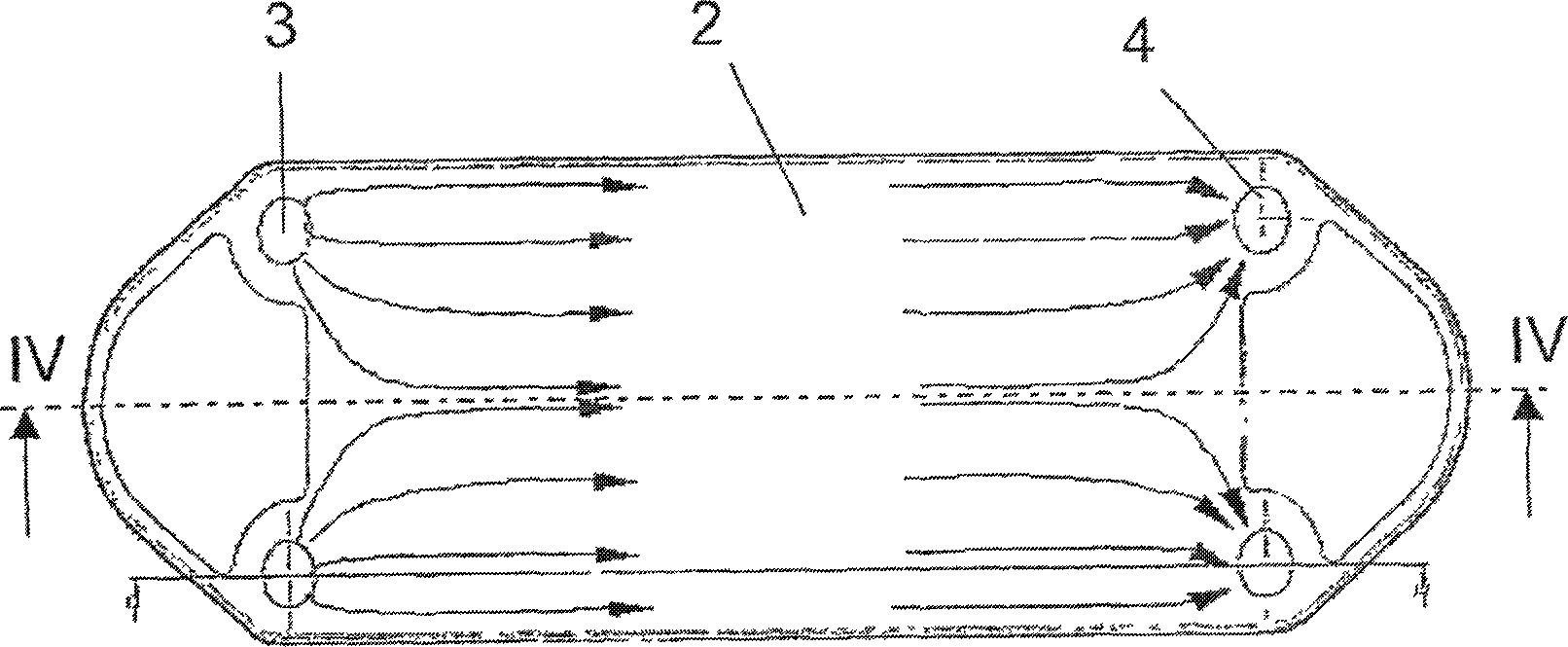

[0025] As shown in the figure, the charge air / coolant cooler 1 as a heat exchanger between the charge air and the coolant has a plurality of coolant pans 2 stacked on top of each other. Here, two inflow holes 3 and two outflow holes 4 are respectively provided in each cooling liquid pan 2 , through which the cooling liquid as a heat exchange medium enters the gap in the middle of the cooling liquid pan 2 or flows out there. The direction of flow is indicated by arrows in the figure. After the coolant enters through the inflow hole 3, it spreads in the entire width of the gap in the middle of the coolant plate 2, and evenly flows to the outflow hole 4 (see image 3 ), so that the entire length and width of the intermediate space between the inlet hole 3 and the outlet hole 4 is flowed through, so that the charge air / coolant cooler 1 between the coolant pans 2, The heat transfer of the charge air to be cooled is optimized.

[0026] The holes 3 and 4 in the coolant tray 2 place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com