Blade, aeration combined typed bleeding machine

A combined, aerator technology, used in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing the water surface, expensive construction, damage to shrimp, etc. Good oxygen effect, improved dissolved oxygen, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

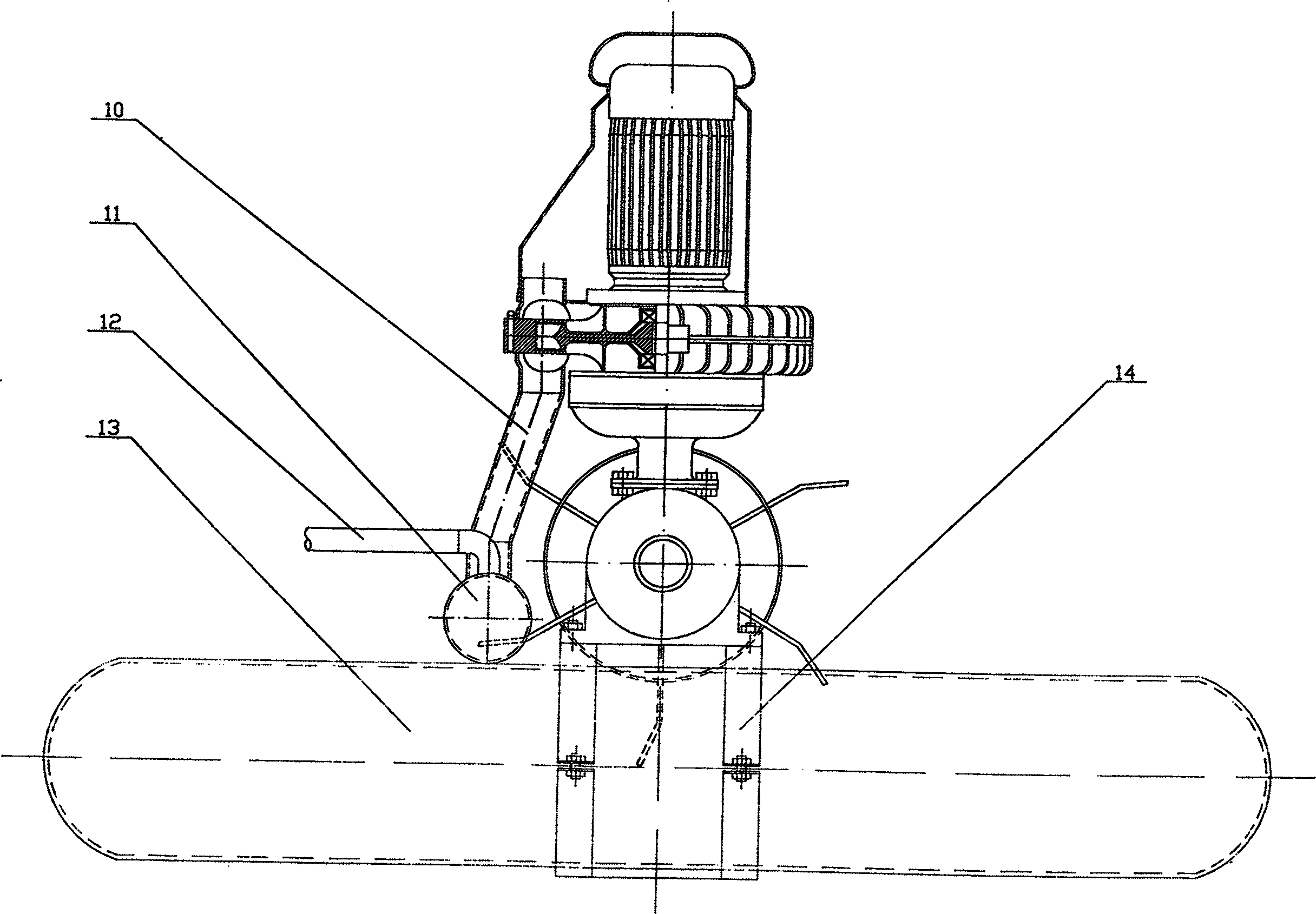

[0011] By the attachment figure 1 As shown in -3, a paddle and gas-filled combined aerator of the present invention includes an electric motor 2, a high-pressure fan 3, a speed reduction mechanism connected from top to bottom, and a paddle wheel 9 and a storage device connected to it. Air bag 11, air distribution pipe 12 and pontoon 13; the motor 2 is surrounded by a wind deflector 1, which also plays a waterproof role; the output shaft of the motor directly drives the main shaft of the high-pressure fan 3, and the outlet pipe of the high-pressure fan 10 is connected to the air storage bag 11, the air storage bag is equipped with a sub-air pipe 12, which communicates with the water body; the main shaft of the high pressure fan is reduced by the planetary gear reducer 4, and then reduced by the bevel gear reducer 5, and the output shaft after changing the direction is connected The blade wheel is connected to the shaft 6, and the end of the connecting shaft is connected to the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com