One-off meal box possessing self heating function

A one-time, self-heating technology, used in food heating containers, shock-sensitive items, clothing, etc., can solve the problems of poor fit between the lid and the bottom half shell, unsuitable for outdoor environments, inconvenient to carry and open, etc. To achieve the effect of convenient and reliable opening, improve flexibility, and facilitate opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

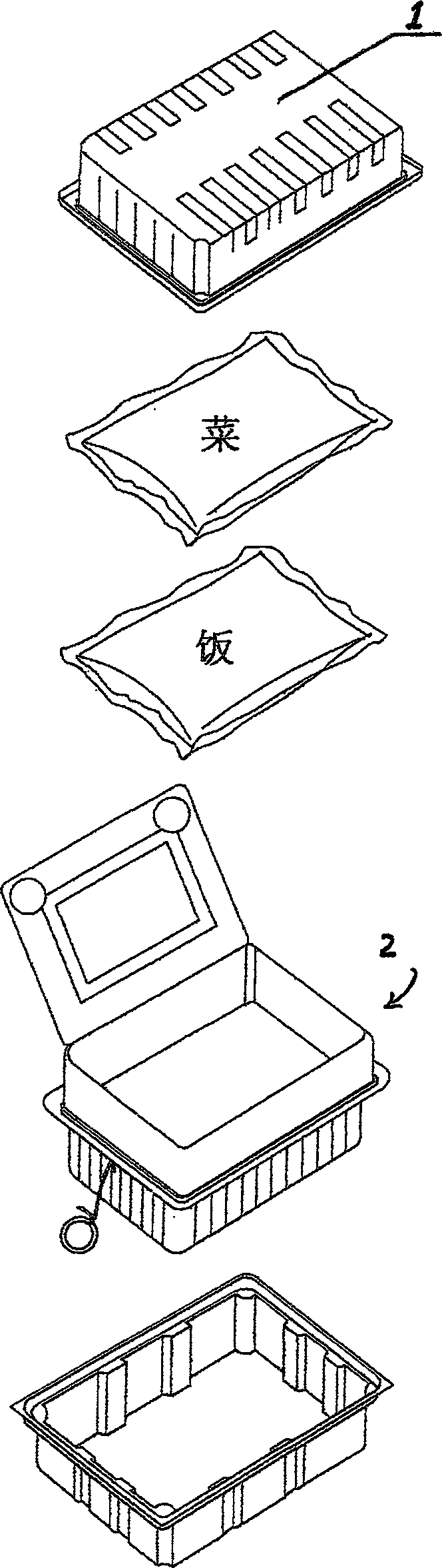

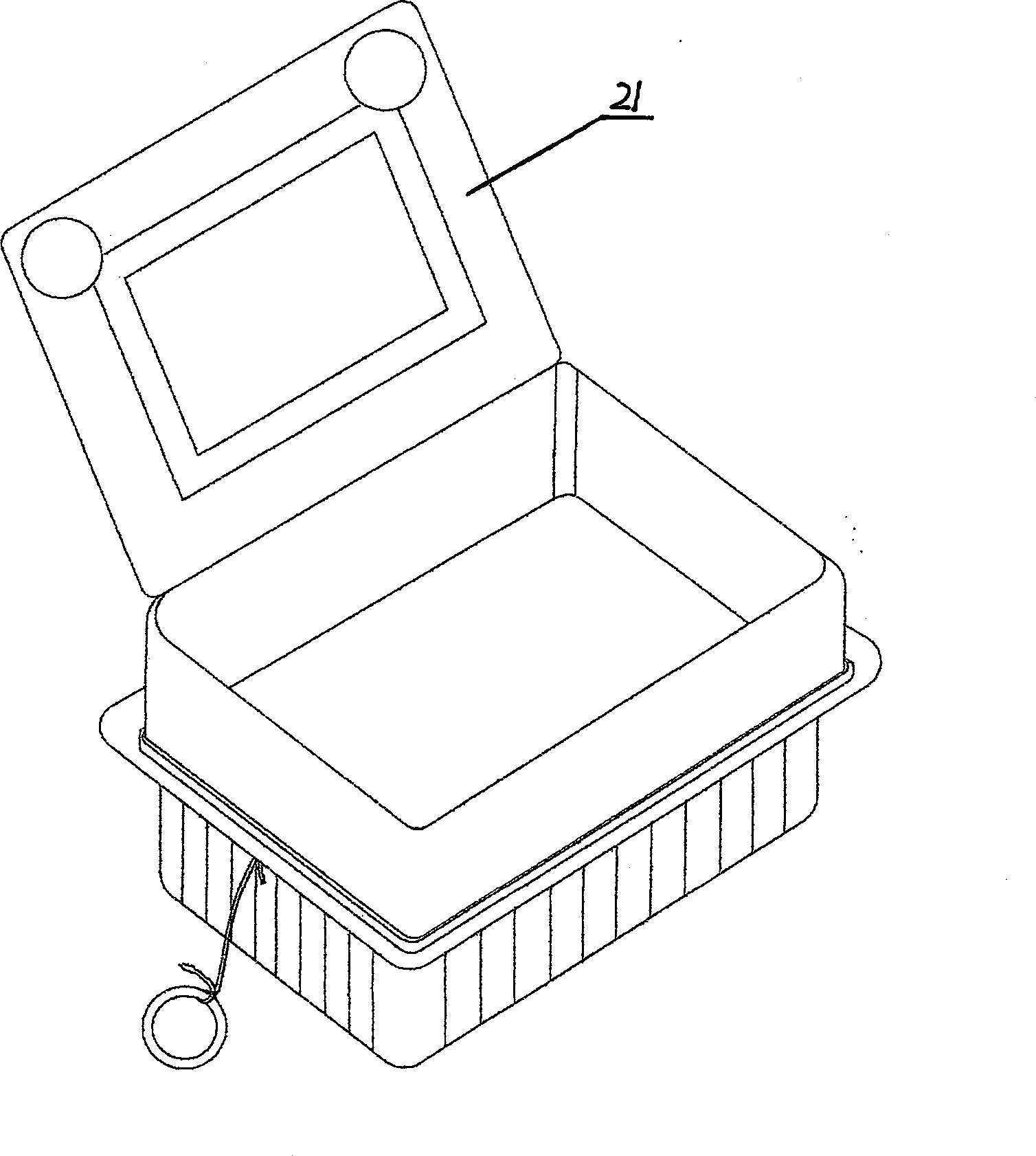

[0027] The structure of the disposable lunch box with self-heating function in this embodiment is as follows: figure 1 , 2 As shown in -8, it includes an outer box 1 made of corn oranges, an inner tank 2, an antifreeze bag 25 and a calcium oxide heating bag 24, and the inner tank 2 is contained in the outer box 1; the inner tank 2 is a double-layer box structure, and the There is an interval 23 between the layers, above the interval 23 is a food chamber 22, the top of the inner tank 2 has an openable upper cover 21, and below the interval 23 is a heating chamber 26, in which are placed an antifreeze agent bag 25 and a calcium oxide heating bag 24 , the antifreeze bag 25 and the calcium oxide heating bag 24 are provided with notches 27 on one side, and the antifreeze bag 25 and the calcium oxide heating bag 24 are fixedly connected together by a fixed point 29 on one side; the other side is respectively passed through a binding point 30 Fasten with the box body edge part of fo...

Embodiment 2

[0032] The difference from Example 1 is:

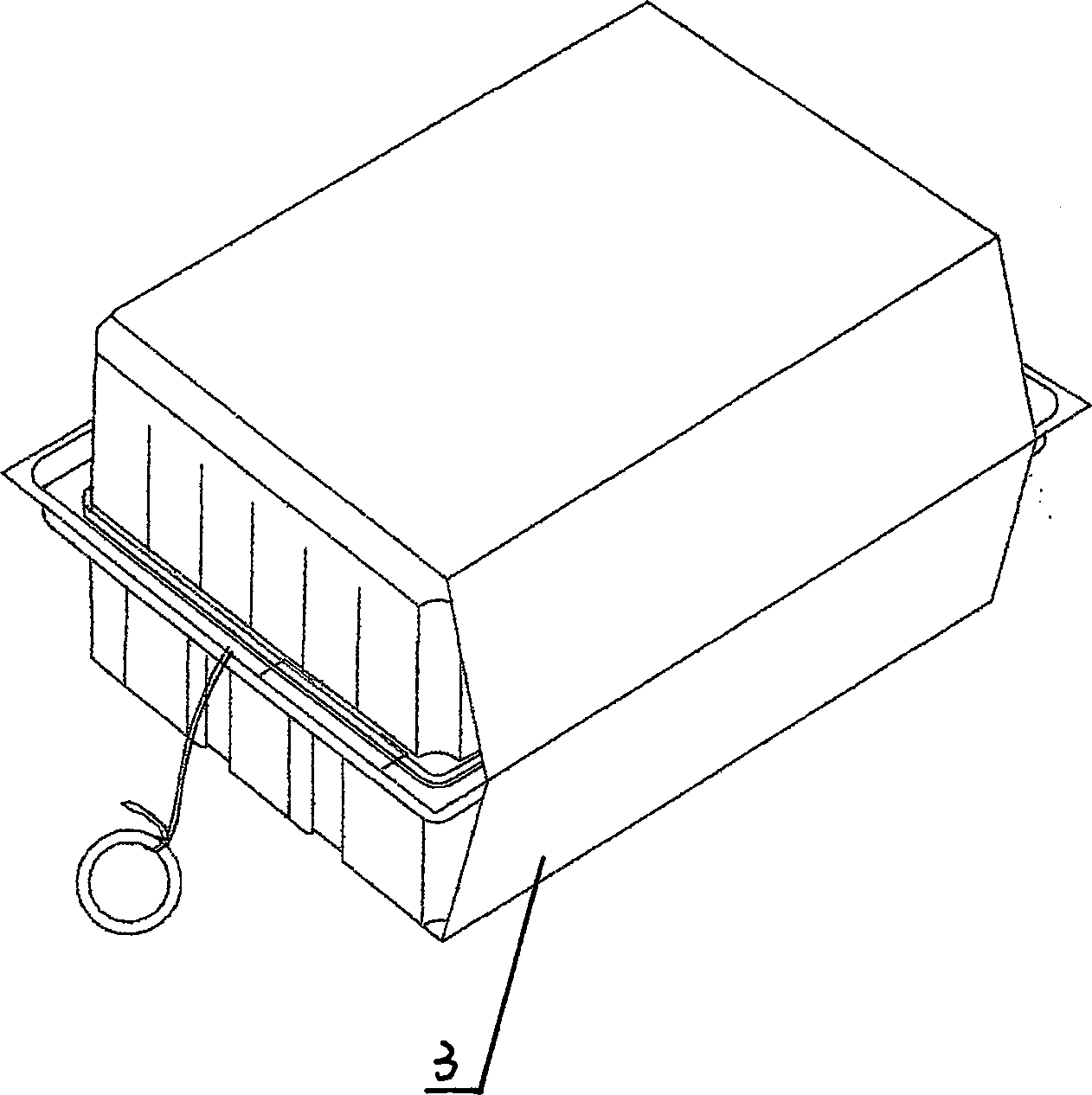

[0033] The gap 23 leaves a gap between the box body of the food cavity 22 and the heating cavity 26, so that after the steam passes through, the dishes above the soft structure upper cover 21 of the food cavity 22 in the outer box 1 is also heated at the same time. Such as figure 2 As shown, an overcoat 3 is added on the outside of the outer box 1 to reinforce the cooperation of the upper and lower halves of the outer box 1, so as to prevent the lunch box from being overturned or the food in the lunch box exposed in case of carelessness. The edge of described heating cavity 26 boxes is provided with a notch 27; during packaging, the opening device of rope-like structure is wound and connected with the notch 27 provided at the edge near the handle ring 28 (see Figure 7 ).

[0034] Antifreeze as crystalline magnesium chloride MgCl 2 ·6H 2 O is the main component, and its composition is 20% crystalline magnesium chloride and 80% w...

Embodiment 3

[0036] The difference with embodiment 1 is: the bottom of the lower half outer box 1 is provided with a boss (see Figure 4 , 8 ), leaving a space between the bottom of the liner 2. Antifreeze as crystalline magnesium chloride MgCl 2 ·6H 2 O is the main component, and its composition is 50% crystalline magnesium chloride and 50% water by weight percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com