Transfer printing thin film in mould, and fabrication method

A technology of in-mold transfer printing and manufacturing methods, applied in the direction of copying/marking methods, chemical instruments and methods, printing, etc., can solve the problems that it is difficult to meet the requirements of non-polluting environment and air manufacturing process, and the cumbersome treatment of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

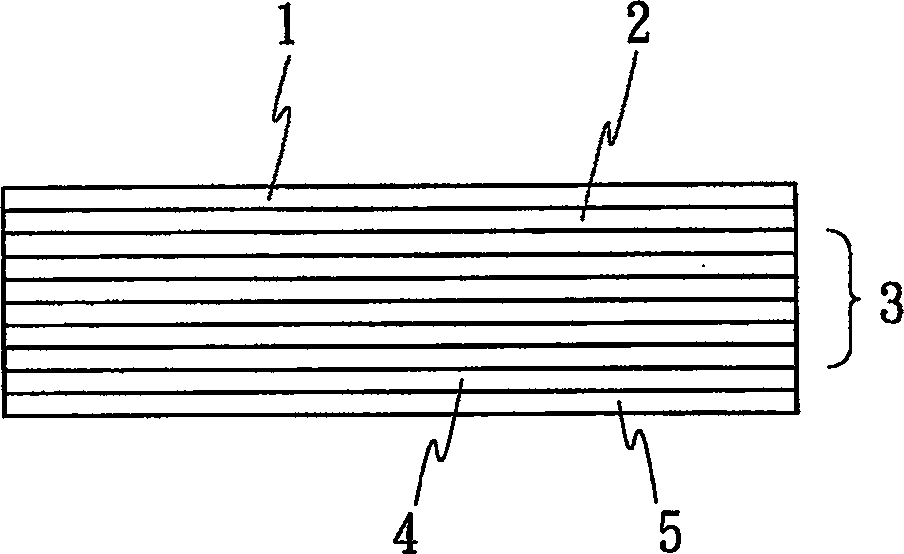

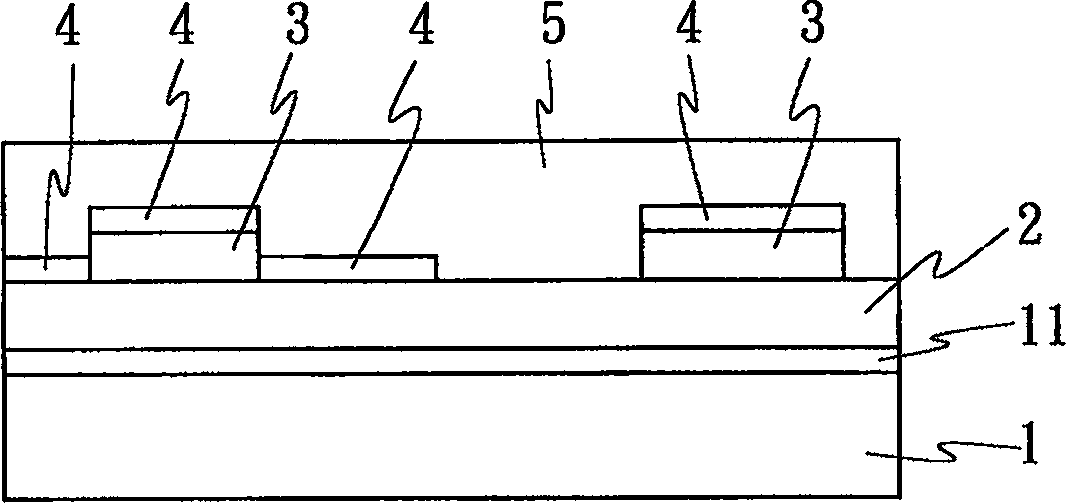

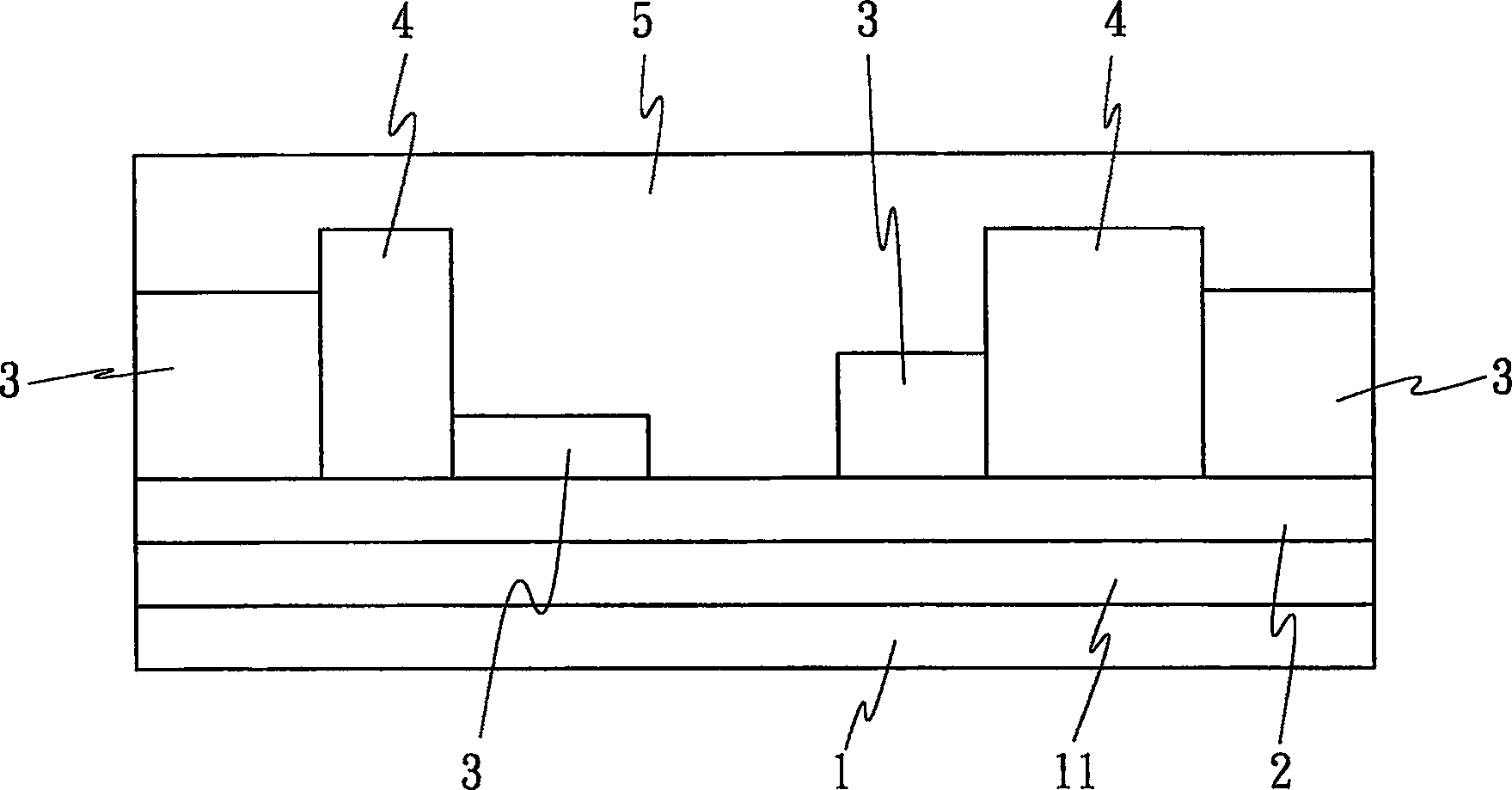

[0021] Such as Figure 1 to Figure 3 As shown, the in-mold transfer film of the present invention mainly includes a transparent base layer 1 with peeling properties and a protective wear-resistant layer 2, an ink pattern coating printing layer 3, and a protective wear-resistant layer formed on the transparent base layer in sequence. Metal layer 4 and adhesive layer 5, and a release layer 11 is provided between the transparent base layer 1 and the protective wear-resistant layer 2; wherein:

[0022] The transparent base layer 1 can be selected as polyester (PET: Polyester), polymethyl methacrylate (PMMA: Polymethyl methacrylate), polycarbonate (PC: Polycarbonate) or polystyrene (PS: Polystyrene), etc. Transparent plastic rubber material;

[0023] The protective wear-resistant layer 2 is a transparent and colored resin layer of inorganic chemical powder particles (it can be a colored or colorless transparent substance), formed on the surface of the transparent base layer 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com