Application method of high dielectric microwave composite material on antenna made

A technology with composite functions and application methods, applied in antennas, antenna parts, waveguide devices, etc., can solve problems such as increased surface wave loss, poor antenna radiation efficiency, narrow bandwidth, etc., and achieve excellent performance and high radiation efficiency with the effect of buff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

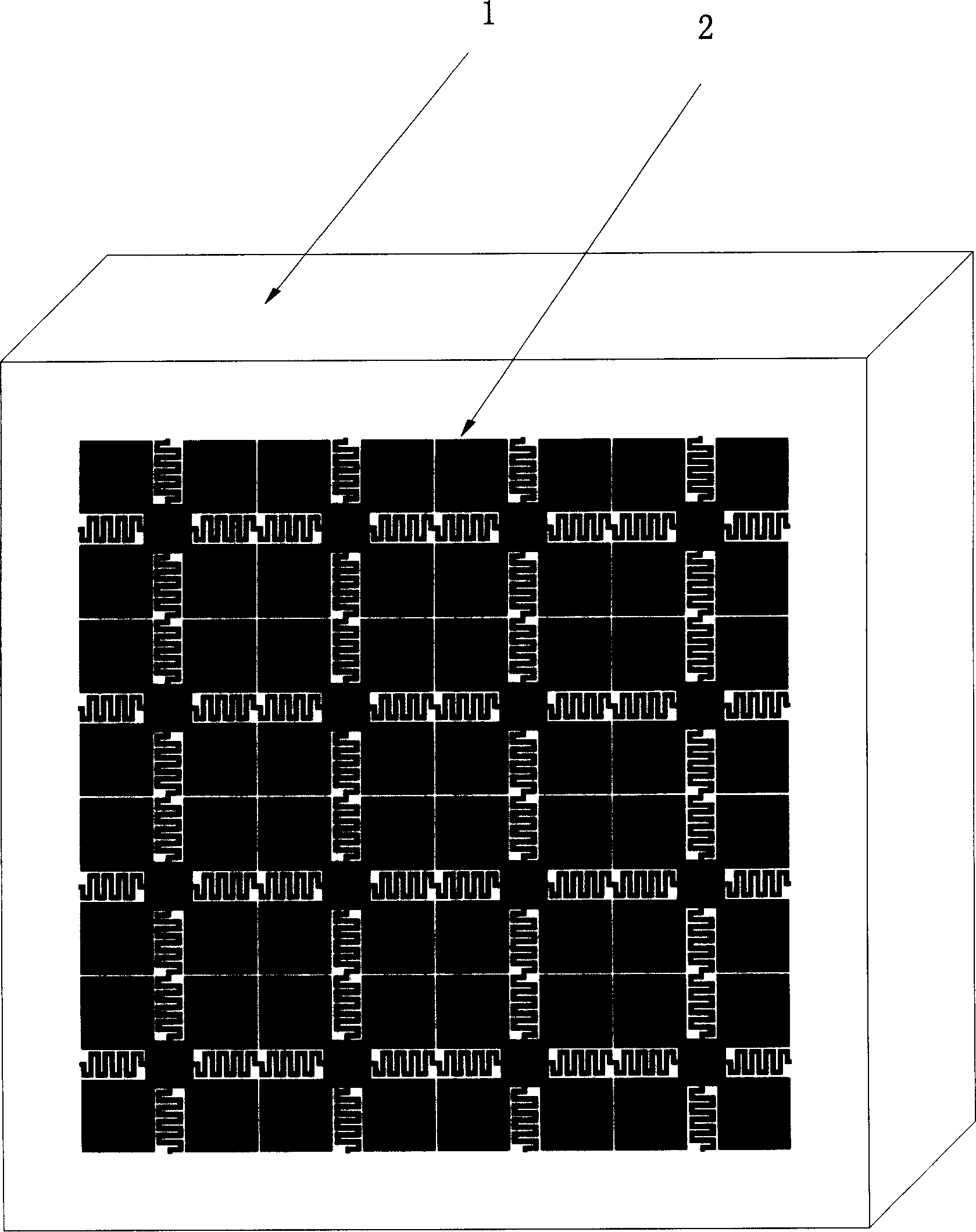

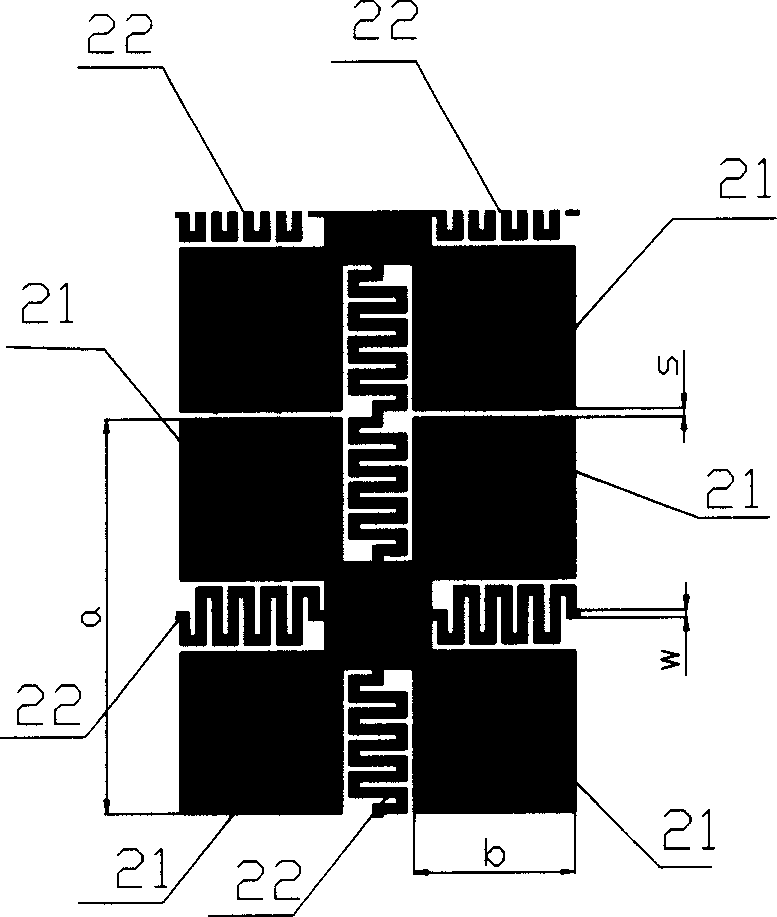

[0024] Such as figure 1 Shown, a kind of application method of high-dielectric microwave composite functional material on the antenna, described high-dielectric microwave composite functional material adopts component to be Sr 1-x Ba x TiO 3 High dielectric microwave ceramic materials. Using the high-dielectric microwave ceramic material as the medium, a periodic electromagnetic bandgap structure is formed on the surface of the medium by standard photolithography process or chemical plating method. The electromagnetic bandgap structure in the figure can be made of metal copper, silver, aluminum or gold. . Such as figure 2 As shown, the electromagnetic band gap structure 2 is a planar structure composed of a plurality of square unit cells, and the unit cell is composed of two curved wires 22 perpendicular to each other arranged in the middle of the unit cell and four wires separated by the wires 22. The conductive block 21 is composed of the conductive block 21, and the c...

Embodiment 2

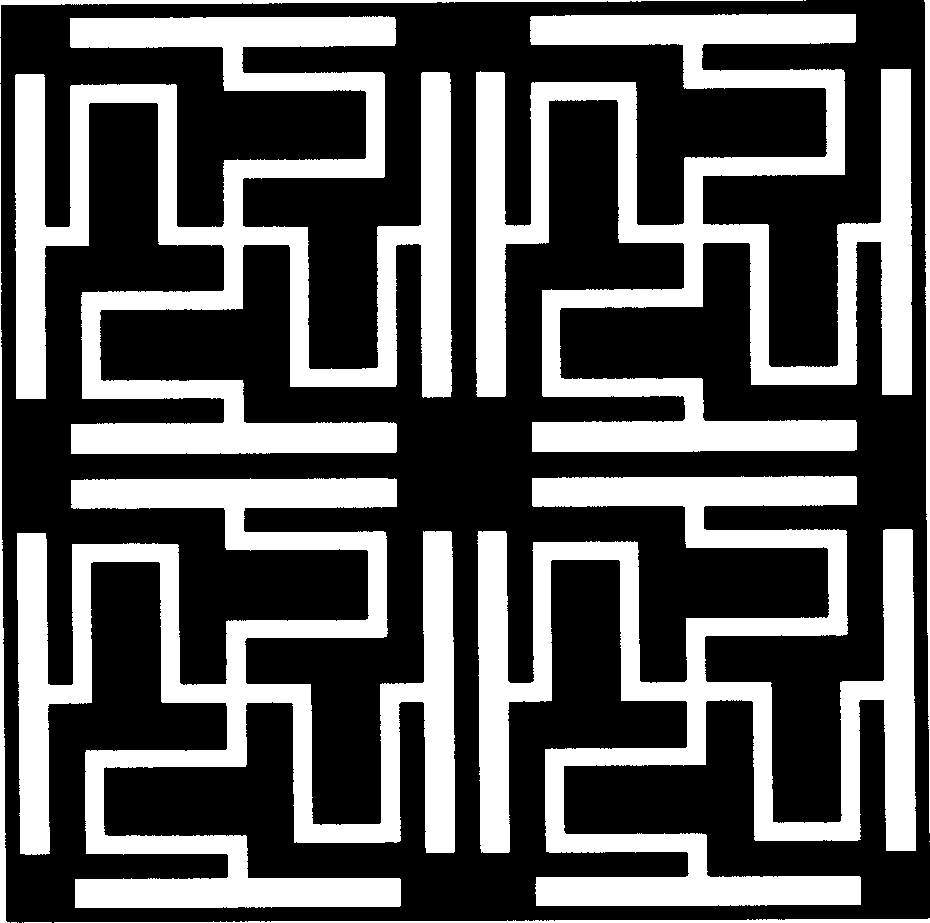

[0030] Such as image 3 As shown, the electromagnetic bandgap structure is a planar structure composed of a plurality of square unit cells, and the edge of the unit cell is provided with four blank bars parallel to the four sides of the unit cell, and the middle part of the unit cell is provided with two vertical bars parallel to each other. A period of interconnected square waveform blank strips, the two ends of each blank strip communicate with the middle parts of the two blank strips, and the part of the unit cell structure except the blank strips and the blank strips is a conductive block.

Embodiment 3

[0032] Such as Figure 4 As shown, the electromagnetic bandgap structure is a planar structure composed of a plurality of square unit cells, the edge of the unit cell is provided with four conductive strips parallel to the four sides of the unit cell, and the middle part of the unit cell is provided with two mutually perpendicular and parallel A period of interconnected square-wave conductive strips, the two ends of each conductive strip communicate with the middle of the two conductive strips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com