Fireproof and thermal insulating nylon hose and method for production thereof

A hose and nylon technology, used in the field of liquid or gas conveying pipes, can solve the problems of unsatisfactory heat insulation and flame retardant effect and bending radius, low pressure resistance, heat resistance and fire resistance, etc., to reduce the weight of the pipe body and the handling Worker strength, good high pressure resistance, and the effect of reducing the bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

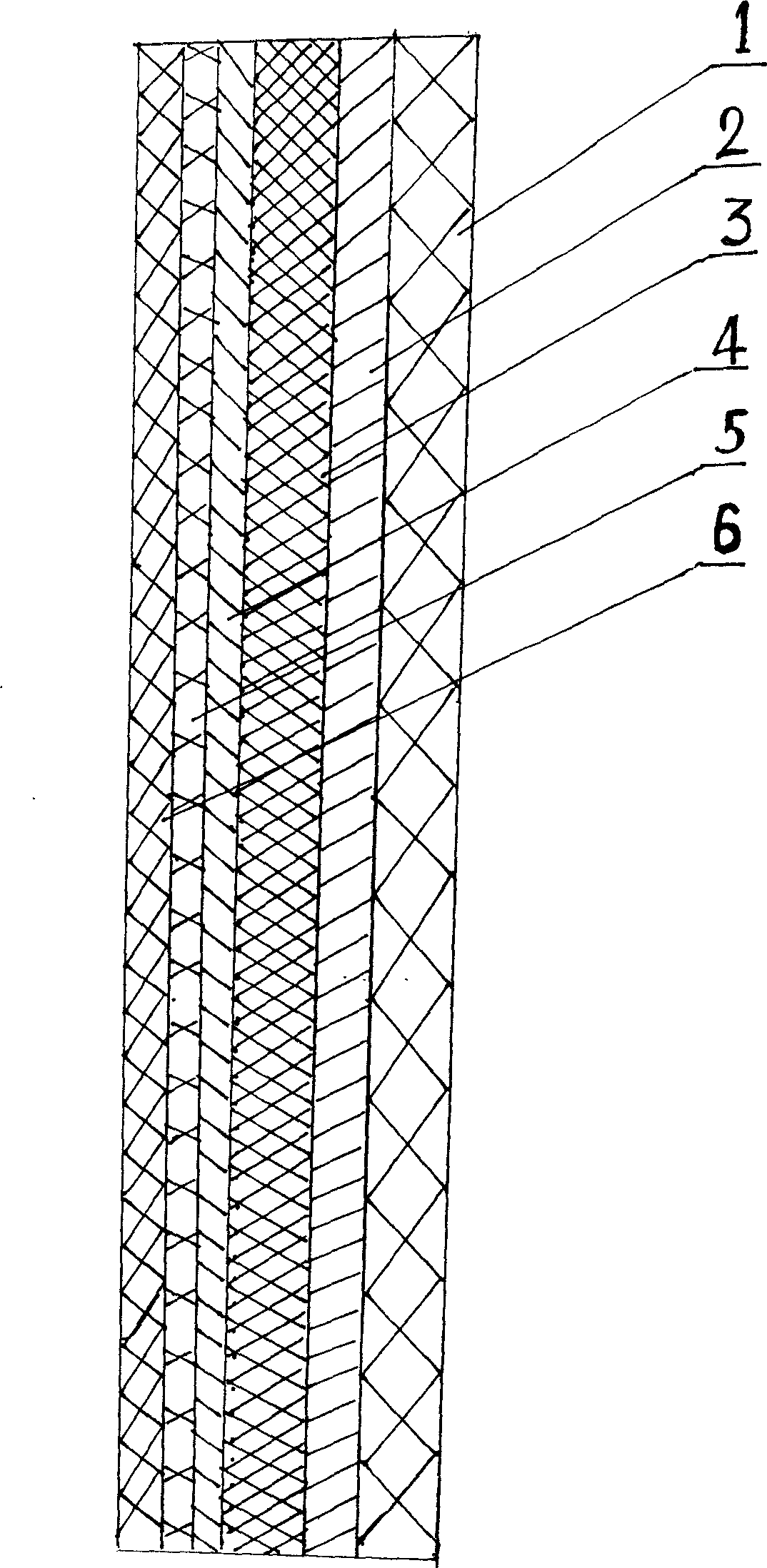

[0016] Example 1, such as figure 1 As shown, the pipe body of the present invention consists of nylon pipe layer 1, wire winding layer 2, heat-insulating and flame-retardant material layer 3, metal braiding layer 4, refractory fiber cloth layer 5 and polyurethane flame retardant layer 6 from inside to outside.

[0017] The preparation method of the present invention is as follows:

[0018] A. Production of inner core tube: The production method is basically the same as that of ordinary plastic tubes, that is, take nylon 6 raw material particles and dry them at 110-120°C for 2 hours, add them to the hopper of the extruder, start the power unit, and extrude at 180°C. The vacuum device cools the water tank, and leads out the hose through the traction device, and the thickness of the pipe wall is 5mm.

[0019] B. Wrapping metal wire: First, use a plying machine to ply according to the number of shares required, and determine the diameter of the metal wire plying root data. The ge...

Embodiment 2

[0024] Example 2, such as figure 1 As shown, the pipe body of the present invention consists of nylon pipe layer 1, wire winding layer 2, heat-insulating and flame-retardant material layer 3, metal braiding layer 4, refractory fiber cloth layer 5 and polyurethane flame retardant layer 6 from inside to outside.

[0025] The preparation method of the present invention is as follows:

[0026] A. Production of inner core tube: The production method is basically the same as that of ordinary plastic tubes, that is, take nylon 10 raw material particles and dry them at 110-120°C for 3 hours, add them to the hopper of the extruder, start the power unit, and extrude at 200°C. The vacuum device cools the water tank, and leads out the hose through the traction device, and the thickness of the pipe wall is 3mm.

[0027] B. Wrapping metal wire: First, use a plying machine to ply according to the number of shares required, and determine the diameter of the metal wire plying root data. The g...

Embodiment 3

[0032] Example 3, such as figure 1 As shown, the pipe body of the present invention consists of nylon pipe layer 1, wire winding layer 2, heat-insulating and flame-retardant material layer 3, metal braiding layer 4, refractory fiber cloth layer 5 and polyurethane flame retardant layer 6 from inside to outside.

[0033] The preparation method of the present invention is as follows:

[0034] A. Production of inner core tube: The production method is basically the same as that of ordinary plastic tubes, that is, take monomer cast nylon raw material particles and dry them at 110-120°C for 2.5 hours, add them to the hopper of the extruder, start the power unit, and extrude at 190°C , through the cooling water tank of the vacuum device, and lead out the hose through the traction device, the thickness of the pipe wall is 2mm.

[0035] B. Wrapping metal wire: First, use a plying machine to ply according to the number of shares required, and determine the diameter of the metal wire pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com