Waste gas treatment equipment employing scrubber and membrane bioreactor and method thereof

A technology of waste gas treatment equipment and bioreactor, which is applied in biological water/sewage treatment, separation methods, chemical instruments and methods, etc., can solve the problems of high cost of purification and treatment of waste washing liquid, large amount of washing liquid, etc. The effect of exchange volume, low sludge yield and high volumetric benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

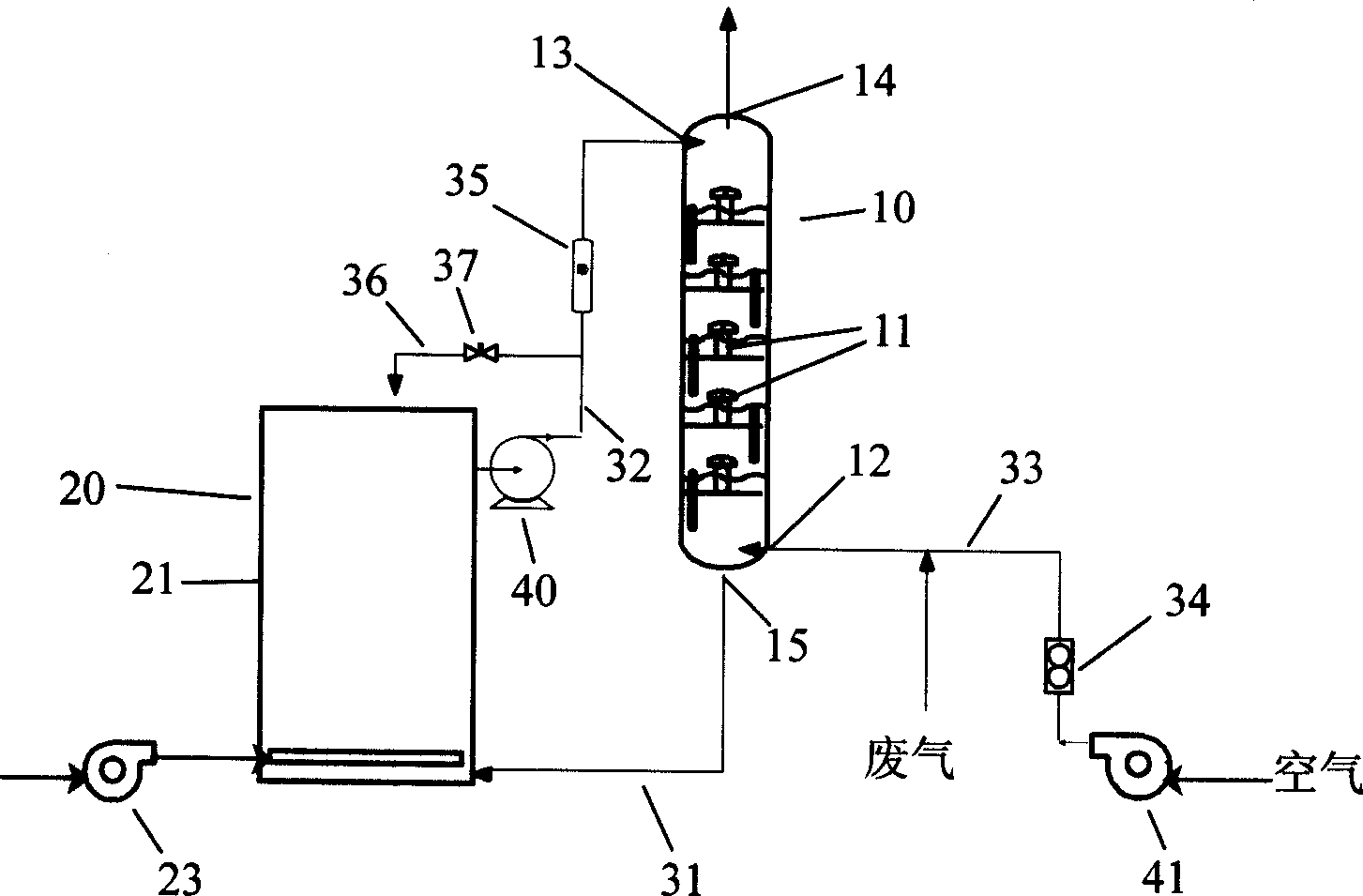

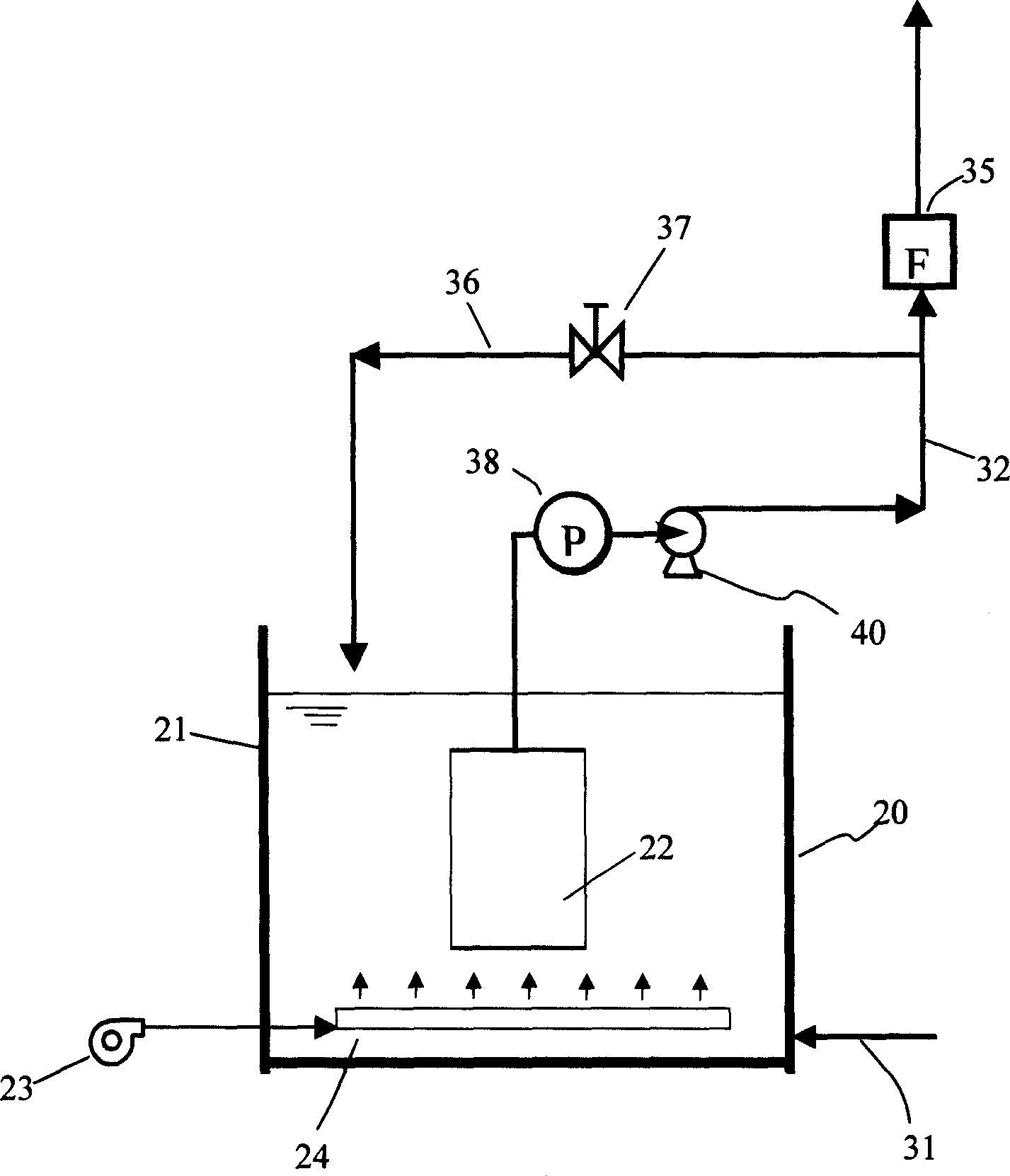

[0044] Organic gas with isopropanol concentration of 200ppmv, with figure 1 and 2 The equipment of the present invention shown was processed, wherein the specifications of the injection unit were shown in Table 1, and the specifications of the membrane separation bioreactor were shown in Table 2. Under the condition of gas-liquid ratio of 710-830, the test was carried out for 13 consecutive days. The result is as image 3 As shown, the removal efficiency of isopropanol in the gas can reach more than 93%.

[0045] parameters

[0046] parameters

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com