Spinning head and filter device for said type of spinning head

A technology of filter device and spinneret, which is applied in spinneret assembly, spinning solution defoaming, textile and papermaking, etc., can solve the problems such as the inability of the spinning head to establish melt flow and the uneven utilization of filter materials, etc. achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

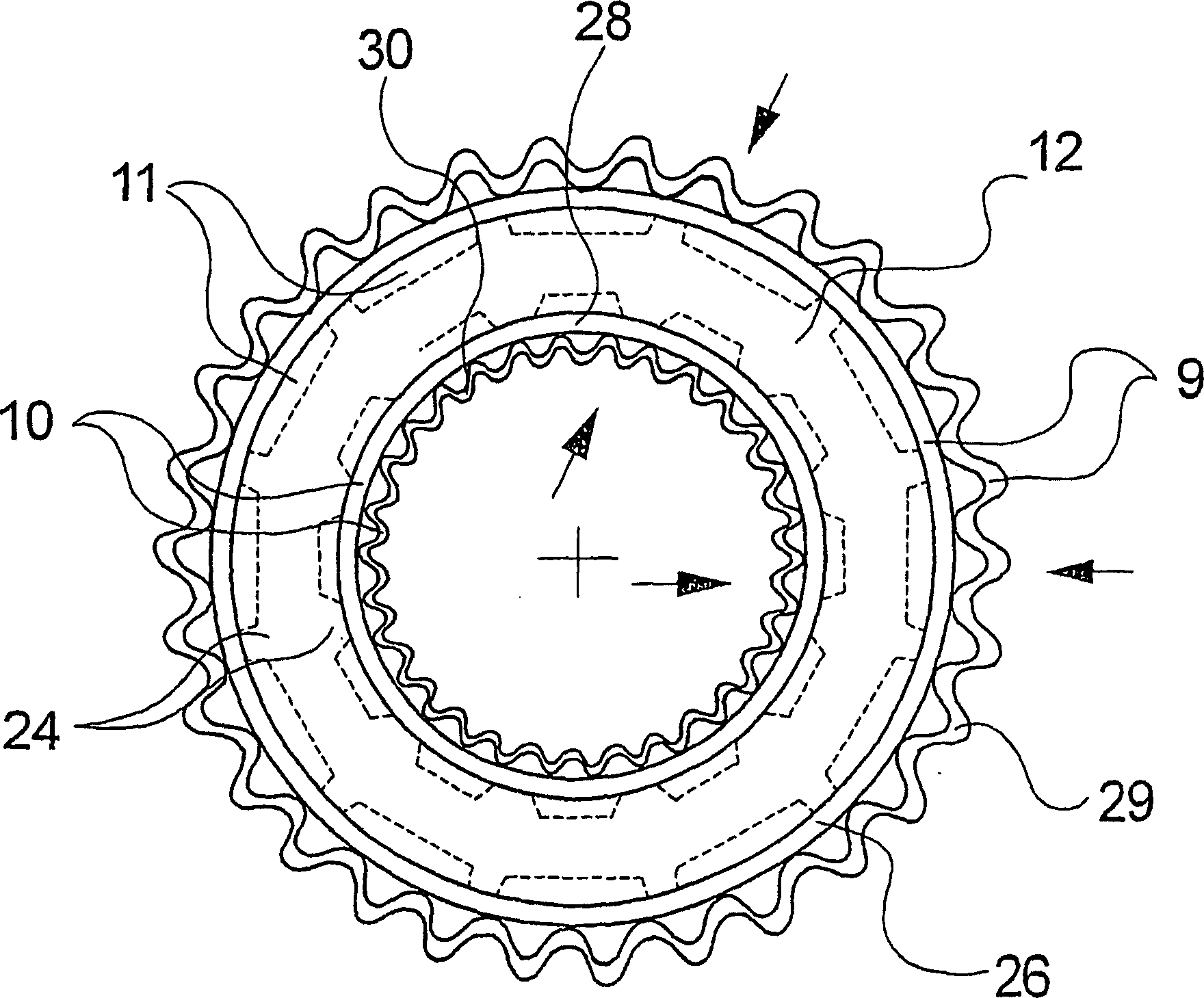

[0025] exist figure 1 A first embodiment of a spinneret according to the invention is schematically shown in longitudinal section. The spinneret has a cylindrical housing 1 . An inner housing flange 7 is formed on the underside of the housing 1 . A spinneret 5 guided inside the housing 1 rests on a housing flange 7 . The spinneret 5 has a plurality of spinneret holes 6 on its bottom side, which are connected to the top side of the spinneret 5 via the spinneret channels 35 .

[0026] An internal thread 8 is formed at the upper end of the housing 1 , via which a feed plate 2 is guided inside the housing 1 . The feed plate 2 has a centrally formed melt inlet 3, which is connected to a melt line (not shown here). The melt inlet 3 is connected to the bottom surface of the feed plate 2 via a feed channel 23 .

[0027] Between the feed plate 2 and the spinneret 5 , a filter device 4 is formed inside the housing 1 , via which the feed channels 23 formed in the feed plate 2 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com