Apparatus for manufacturing articles made of light alloys and the like, and method performed by the apparatus

A technology for light alloys and products, which can be used in manufacturing tools, the configuration of indicating equipment/measuring equipment, casting equipment, etc., and can solve problems such as increasing the complexity of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

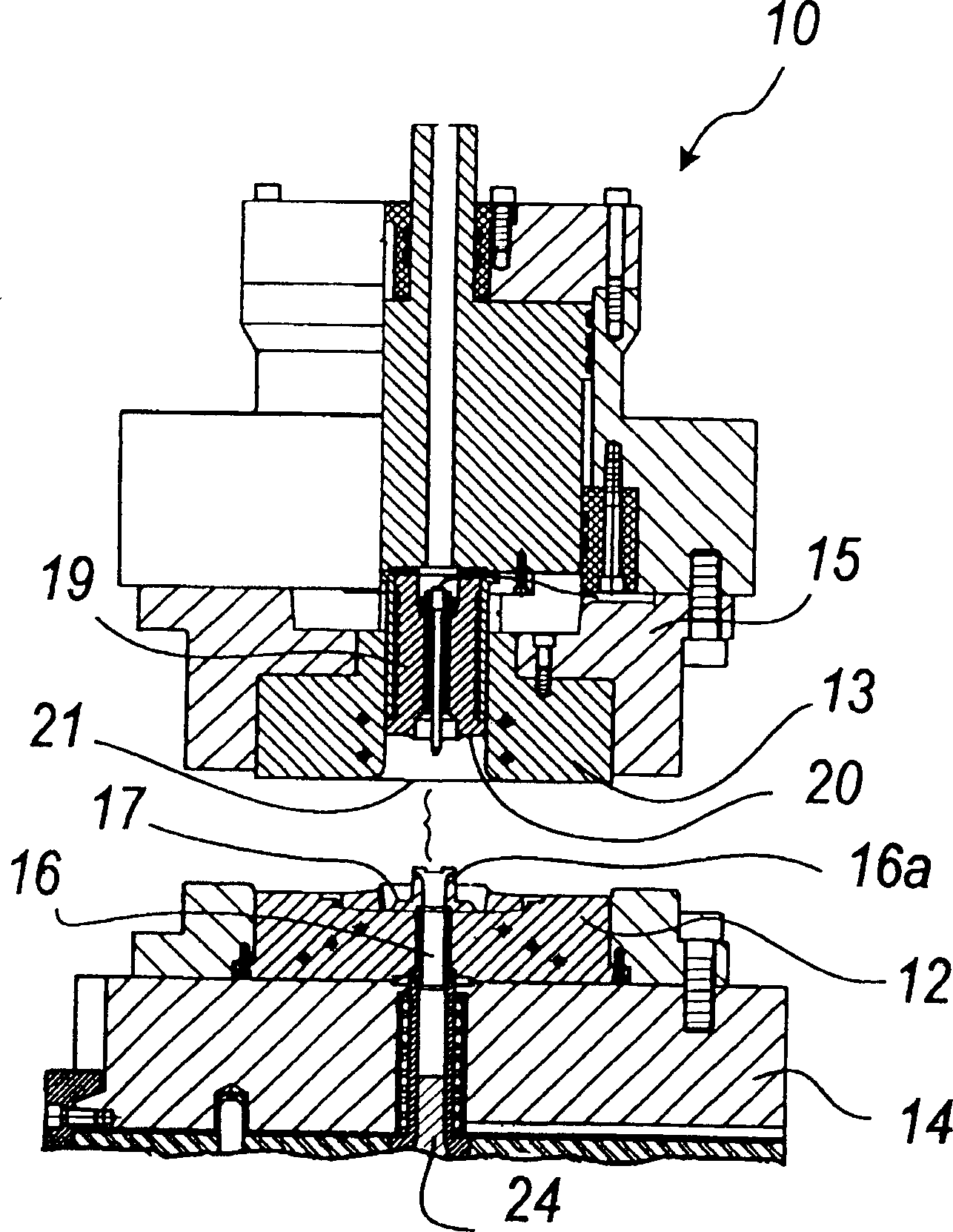

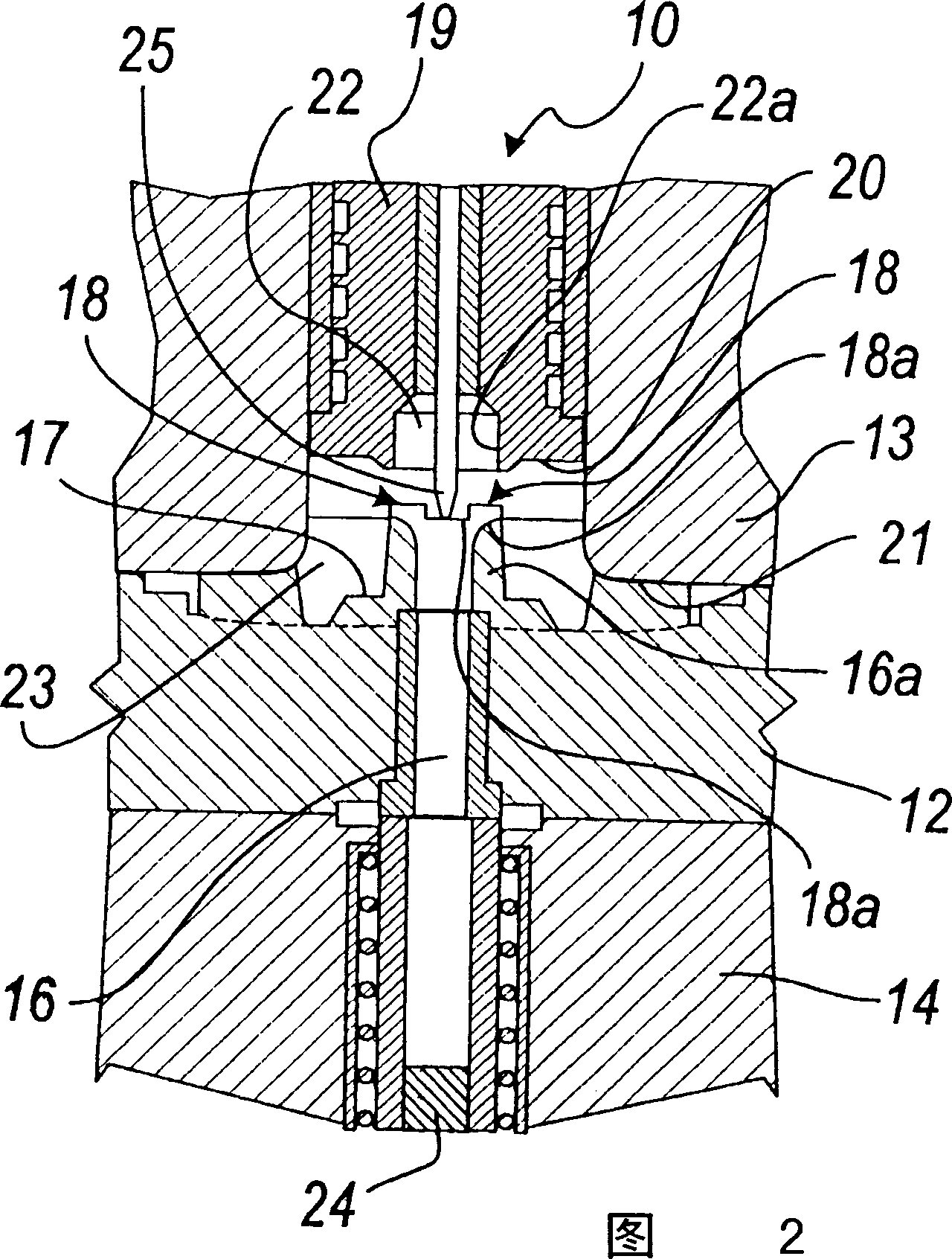

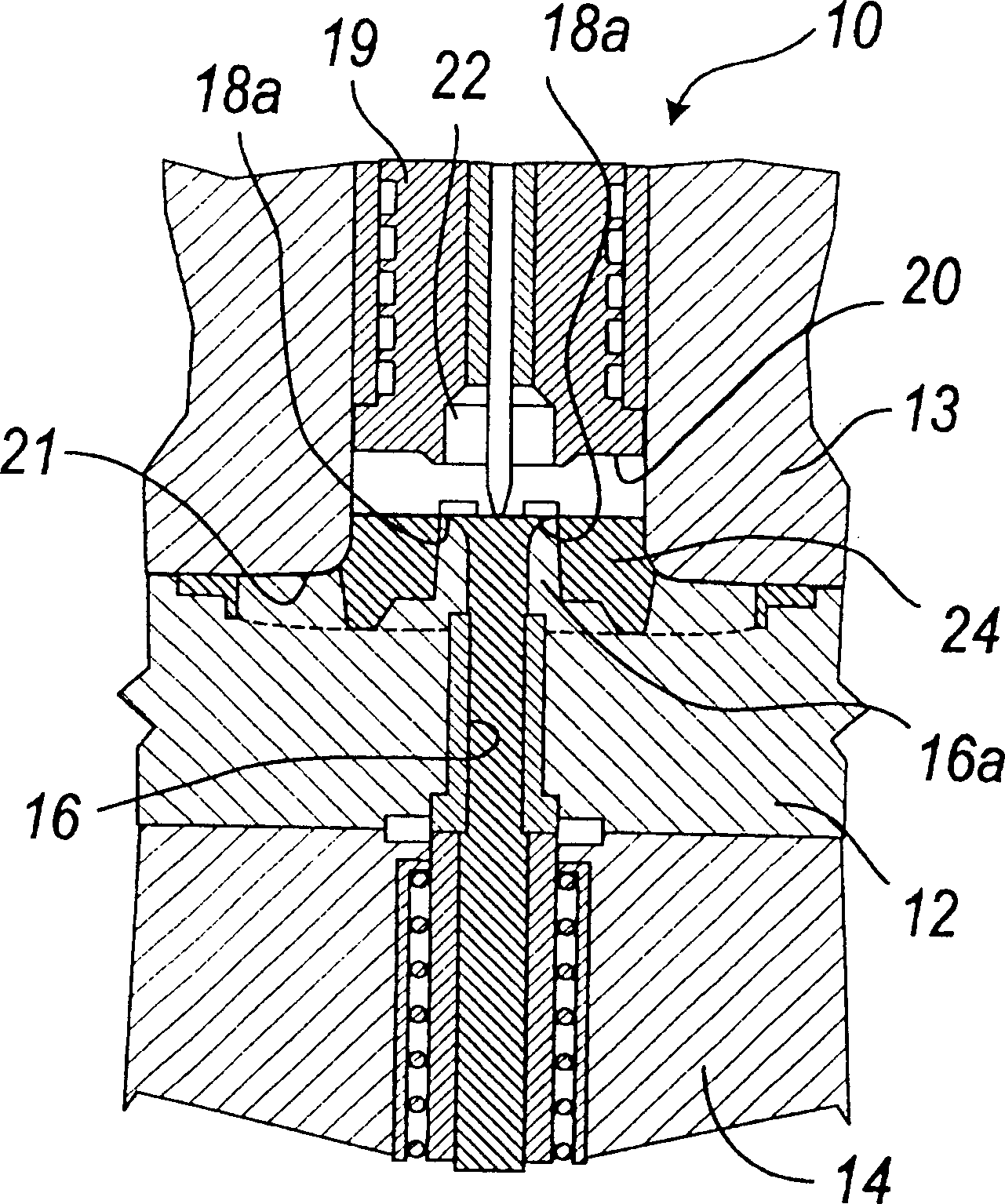

[0025] see Figure 1 to Figure 6 , The device for manufacturing aluminum, aluminum alloy, light alloy and other products according to the first embodiment of the present invention is generally represented by the numeral 10.

[0026] Apparatus 10 is designed to form a central part 11 of a road vehicle wheel and comprises a lower mold part 12 and an upper mold part 13, which are connected to a lower pressing plate 14 and an upper pressing plate 15, respectively.

[0027] The mold parts 12 and 13 can be joined by movement of the upper platen 15 to form the profile 23 of the product being cast.

[0028] A vertical conduit 16 leads into the lower mold portion 12 for conducting liquid metal 24 from a pressurized furnace located below, provided in a manner known in the art.

[0029] The lower mold portion 12 forms a lower mold cavity 17 having at least one concave portion for introducing liquid metal 24 through a plurality of shaped inlets 18 formed in ducts 16 extending upwardly th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com