Procede de fabrication d'un moule et moule obtenu.

A technology for manufacturing molds and molds, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of expensive, complex and troublesome ingot molds, and achieve the effect of long service life, maintaining surface quality, and good surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

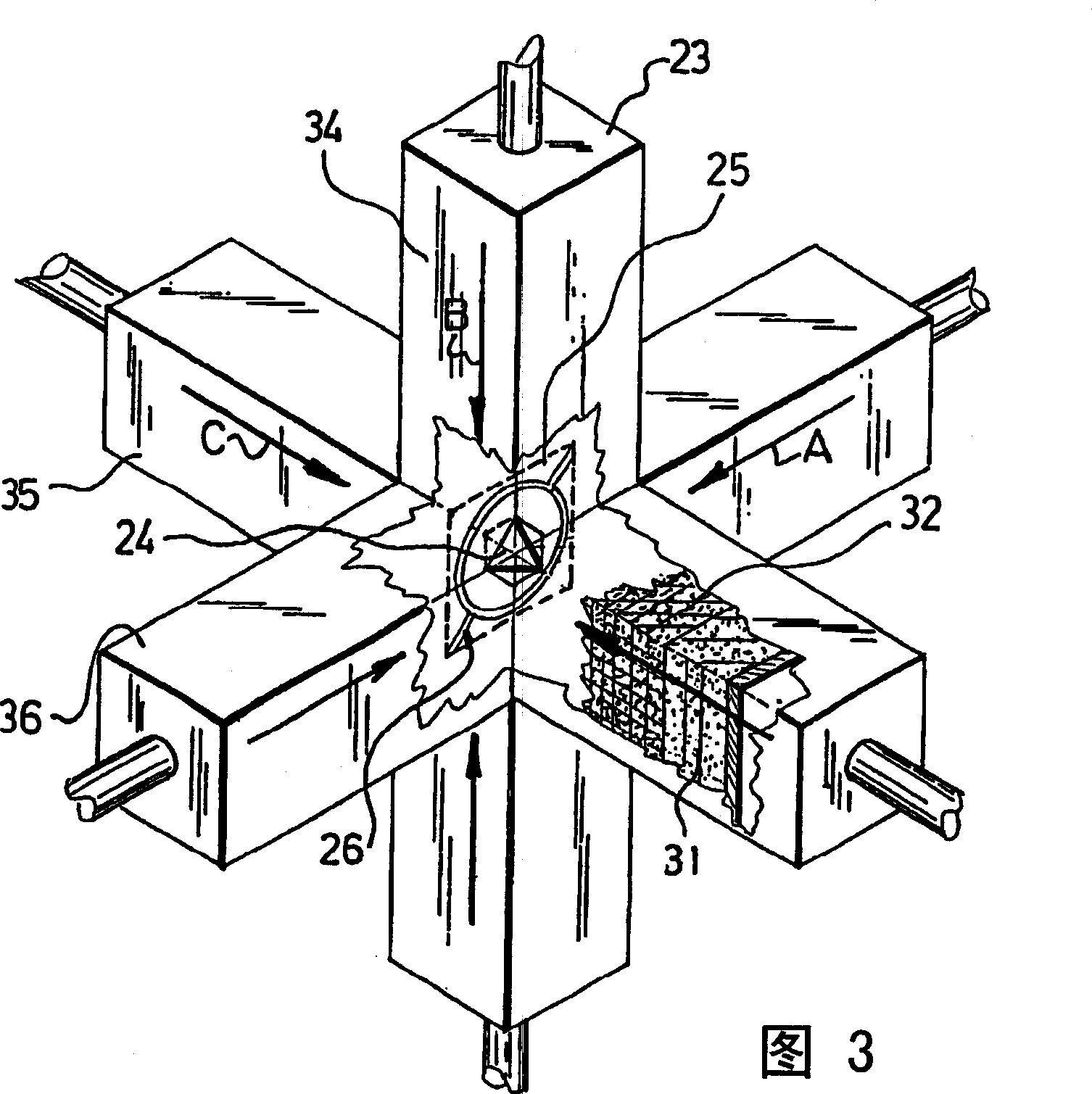

[0077] A mold manufacturing method according to a first form of the present invention is shown in FIG. 1 . A model 3 is placed in a uniaxial press 1, the model having the shape of the article to be manufactured with the mould, the press having a plate 2 of square or rectangular section, transverse along the mid-plane of the model 3 dividing the press into two parts A spacer sheet 7, and a rigid movable or disintegrable tube 4 extending between the mold 3 and the wall of the press 1, which tube is preferably filled.

[0078] Then, the first layer of expanded graphite 5 is formed on one side of the spacer sheet 7, that is, around the first half of the model 3, and the second layer of expanded graphite 6 is formed on the other side of the spacer sheet 7, that is, around the model. The other half of 3. The layers 5 , 6 thus formed completely cover the model 3 .

[0079] The layers of exfoliated graphite are then compressed by driving at least one plate 2 of the press until they ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com