Polyoxyethylene kind block polymer ligand and synthesizing process thereof

A technology of block polymer and polyoxyethylene, applied in the field of medicine and chemical synthesis, can solve the problems of unsatisfactory hepatobiliary system contrast effect, small molecular weight of gadopentetate meglumine, increase the amount of human body detoxification, etc. Simple steps to purify blood vessel walls and products with less toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Preparation of carboxyl-activated benzoic acid

[0055] In the reactor, benzoic acid, N-hydroxysuccinimide, dicyclohexylcarbodiimide (DCC) and N,N-dimethylformamide were added in amounts of 0.244g, 0.322g, 0.5768g and 30ml. The weight ratio of benzoic acid, N-hydroxysuccinimide, dicyclohexylcarbodiimide (DCC) and N,N-dimethylformamide was 1:1.32:2.36:123, and the reaction was carried out at room temperature and stirring for 4 hours , the crude product of carboxyl-activated benzoic acid was obtained. Its structural formula is:

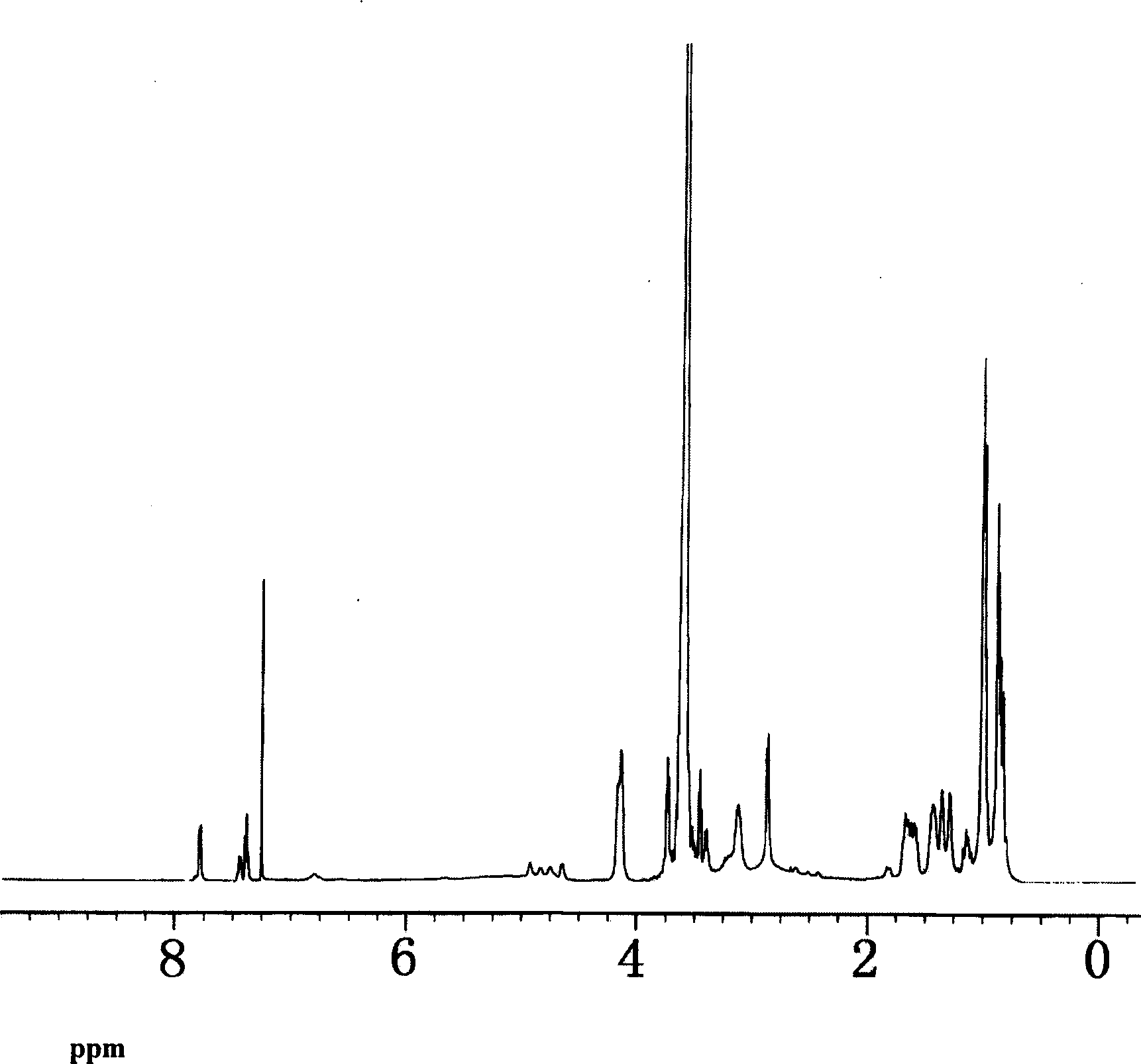

[0056]

[0057] (2) Refinement of carboxyl-activated benzoic acid

[0058] The product obtained in (1) is filtered, and the insoluble matter is removed to obtain the refined product of carboxyl-activated benzoic acid.

[0059] (3) Preparation of crude products of BEN / PEO / DTPA block polymer ligands

[0060] The carboxyl-activated benzoic acid refined product obtained in (2) is used as a raw material, and a polymer modified by terminal ...

Embodiment 2

[0073] (1) Preparation of carboxyl-activated benzoic acid

[0074] In the reactor, benzoic acid, N-hydroxysuccinimide, dicyclohexylcarbodiimide (DCC) and N,N-dimethylformamide were added in amounts of 0.0706g, 0.0931g, 0.1668g and 10ml. The weight ratio of benzoic acid, N-hydroxysuccinimide, dicyclohexylcarbodiimide (DCC) and N,N-dimethylformamide was 1:1.32:2.36:141, and the reaction was carried out at room temperature and stirring for 4 hours , to obtain the crude product of carboxyl-activated benzoic acid,

[0075] (2) Refinement of carboxyl-activated benzoic acid

[0076] With embodiment 1, the refined product of the carboxyl-activated benzoic acid is obtained;

[0077] (3) Preparation of crude products of BEN / PEO / DTPA block polymer ligands

[0078] The carboxyl-activated benzoic acid refined product obtained in (2) is used as a raw material, and a polymer modified by terminal amine group block polyoxyethylene and a solvent are added, and the solvent is N,N-dimethylfor...

Embodiment 3

[0091] (1) Preparation of carboxyl-activated benzoic acid

[0092] Other conditions such as the ratio of raw materials are the same as those in Example 1, except that the reaction is carried out at -4° C. under stirring for 48 hours to obtain a crude product of carboxyl-activated benzoic acid.

[0093] (2) Refinement of carboxyl-activated benzoic acid

[0094] Same as Example 1

[0095] (3) Preparation of crude products of BEN / PEO / DTPA block polymer ligands

[0096] The carboxyl-activated benzoic acid refined product obtained in (2) is used as a raw material, and a polymer modified by terminal amine block polyoxyethylene and a solvent N,N-dimethylformamide are added. The amount of carboxyl-activated benzoic acid refined product, amine-terminated block polyoxyethylene-modified polymer and N,N-dimethylformamide were added in an amount of 0.438g (3()ml DMF), 8.486g and 45ml, respectively. The weight ratio of the carboxyl-activated benzoic acid refined product, the polyoxyethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com