Series-parallel connection active equivalent ball-joint mechanism

An active and effective ball technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of limited driving torque, unfavorable installation and use, and bulky mechanism, and achieve small output torque, easy installation and use, and large working space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the accompanying drawings.

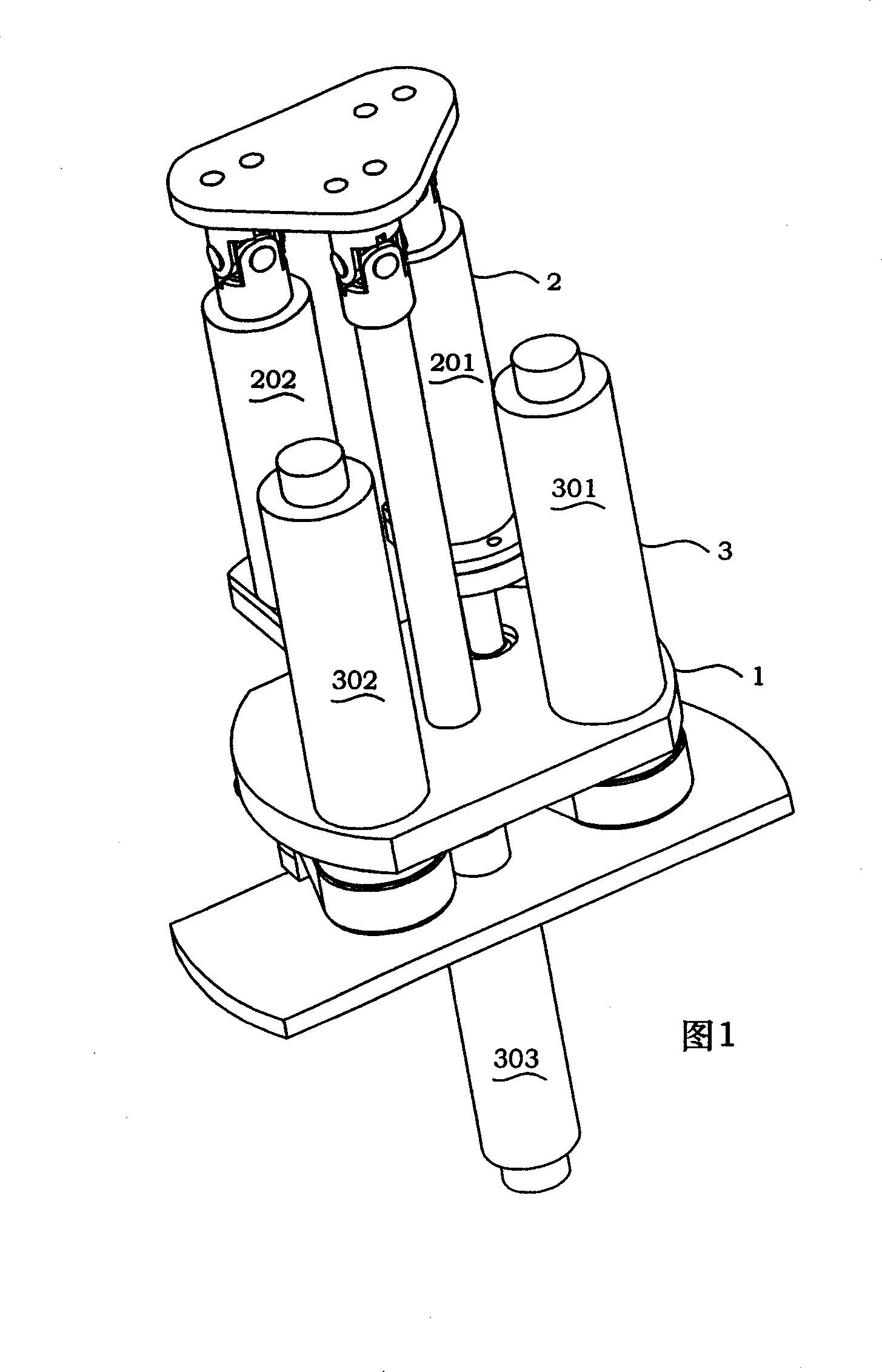

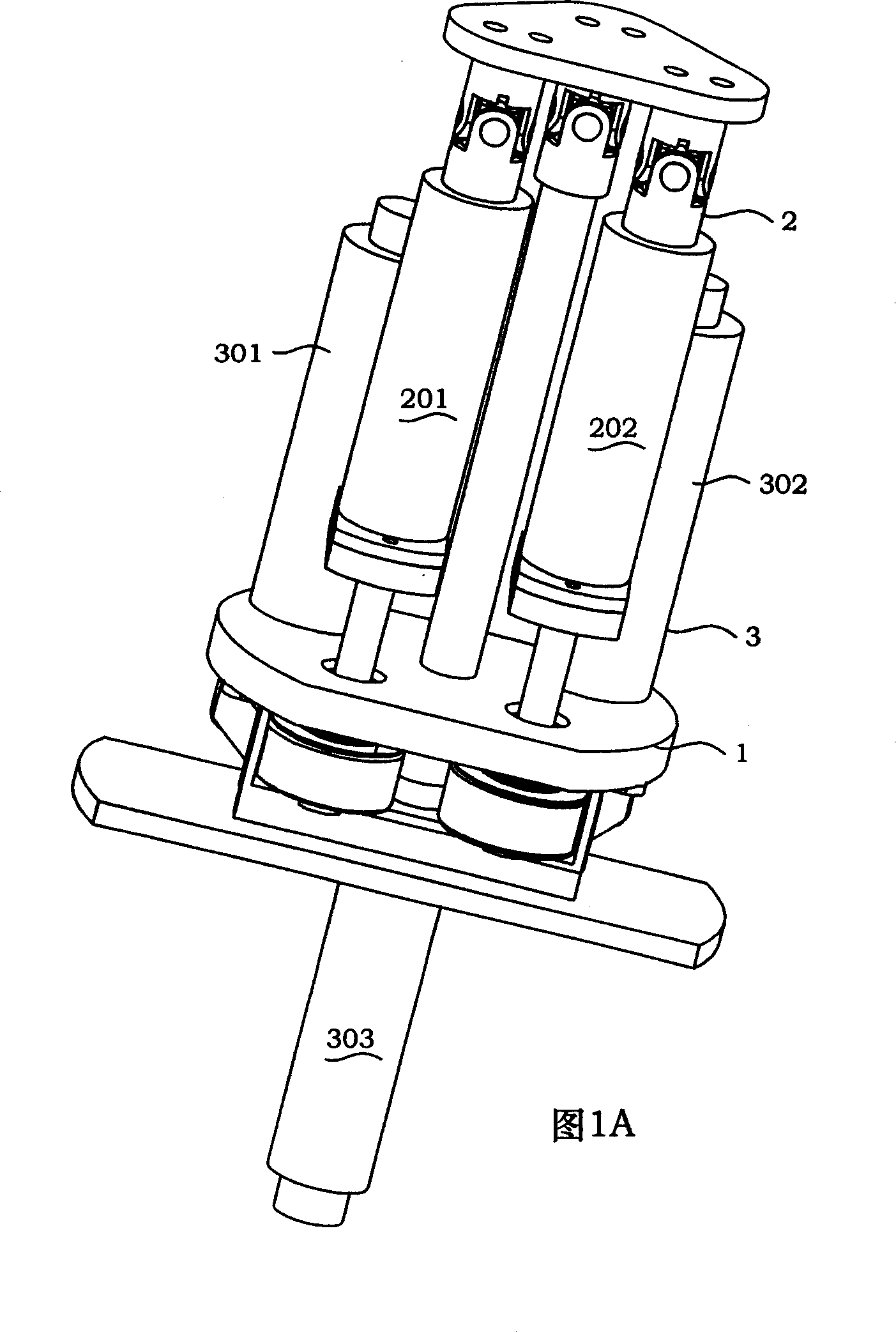

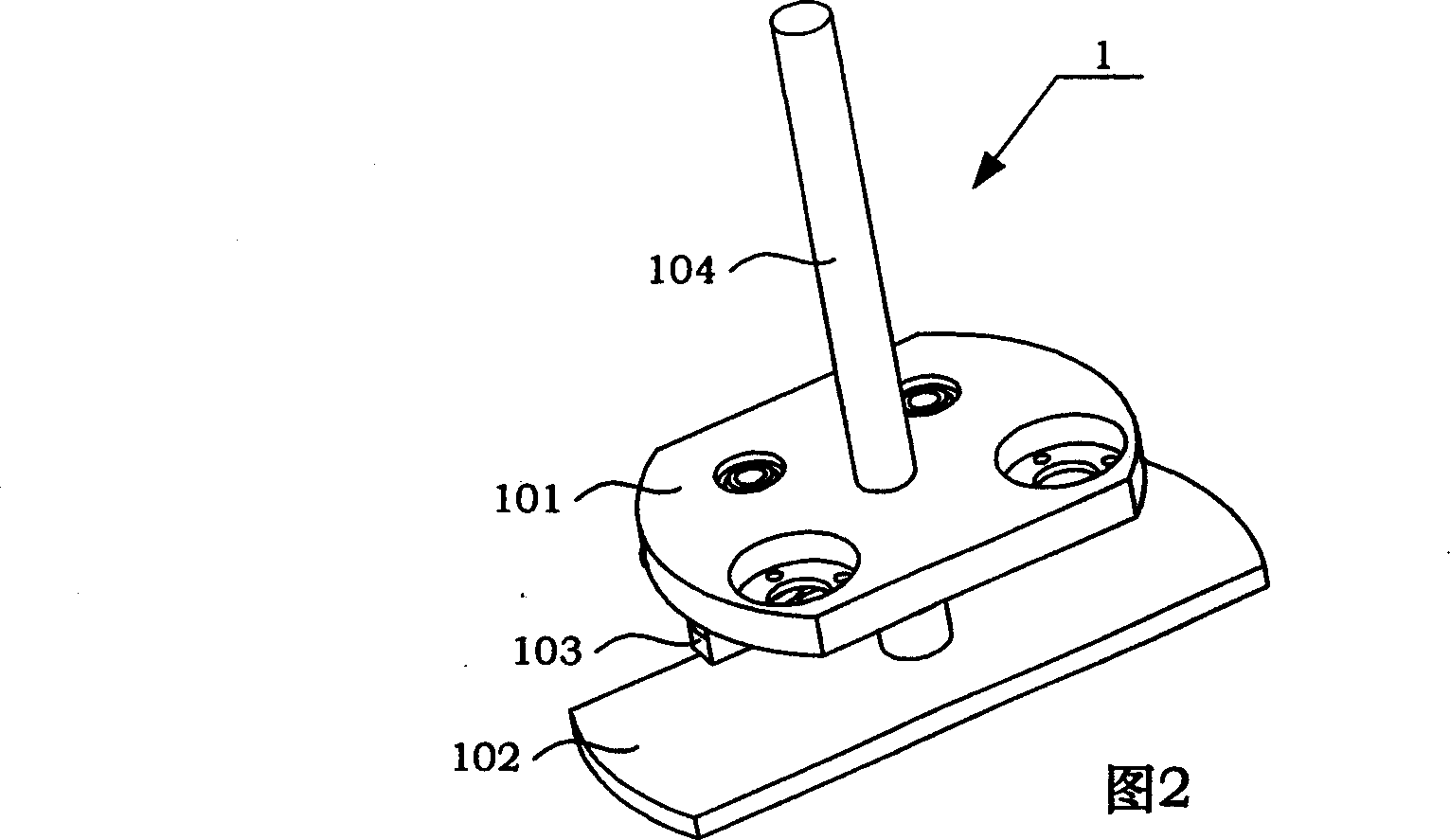

[0019] Referring to FIG. 1 and FIG. 1A, the present invention is a series-parallel active equivalent spherical hinge mechanism, which is composed of a support assembly 1, a connecting assembly 2 and a driving assembly 3. The coupling A 209, the cross universal joint B 210 and the cross universal joint C 211) connect the drive plate 212 and the front connecting plate 101 of the support assembly 1 to realize the connection between the drive plate 212 and the front connecting plate 101. two mutually perpendicular rotational degrees of freedom; a rotational degree of freedom is connected in series between the front connecting plate 101 and the rear connecting plate 102, and the rotation axis of this degree of freedom is perpendicular to the first two rotational degrees of freedom and intersects at a point, thereby realizing a space around the Equivalent spherical j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com