High-strength hot-dip galvanized steel sheet with excellent spot weldability and stability of material properties

A technology of hot-dip galvanized steel sheet and temperature setting, which is applied in the field of hot-dip galvanized steel sheet, which can solve the problems of insufficient stability of steel sheet material and undisclosed steel sheet, etc., and achieve the effect of excellent spot weldability and excellent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

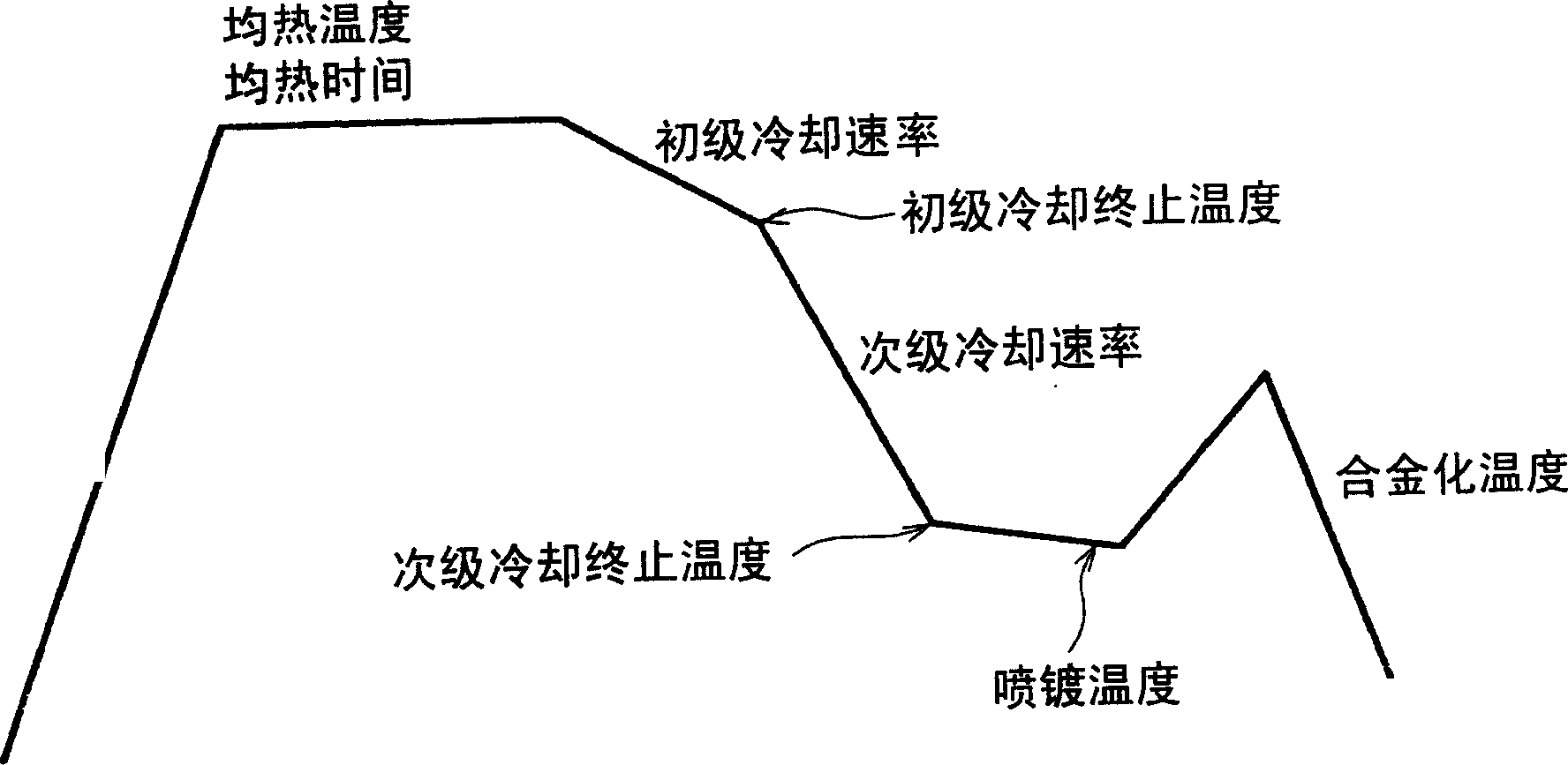

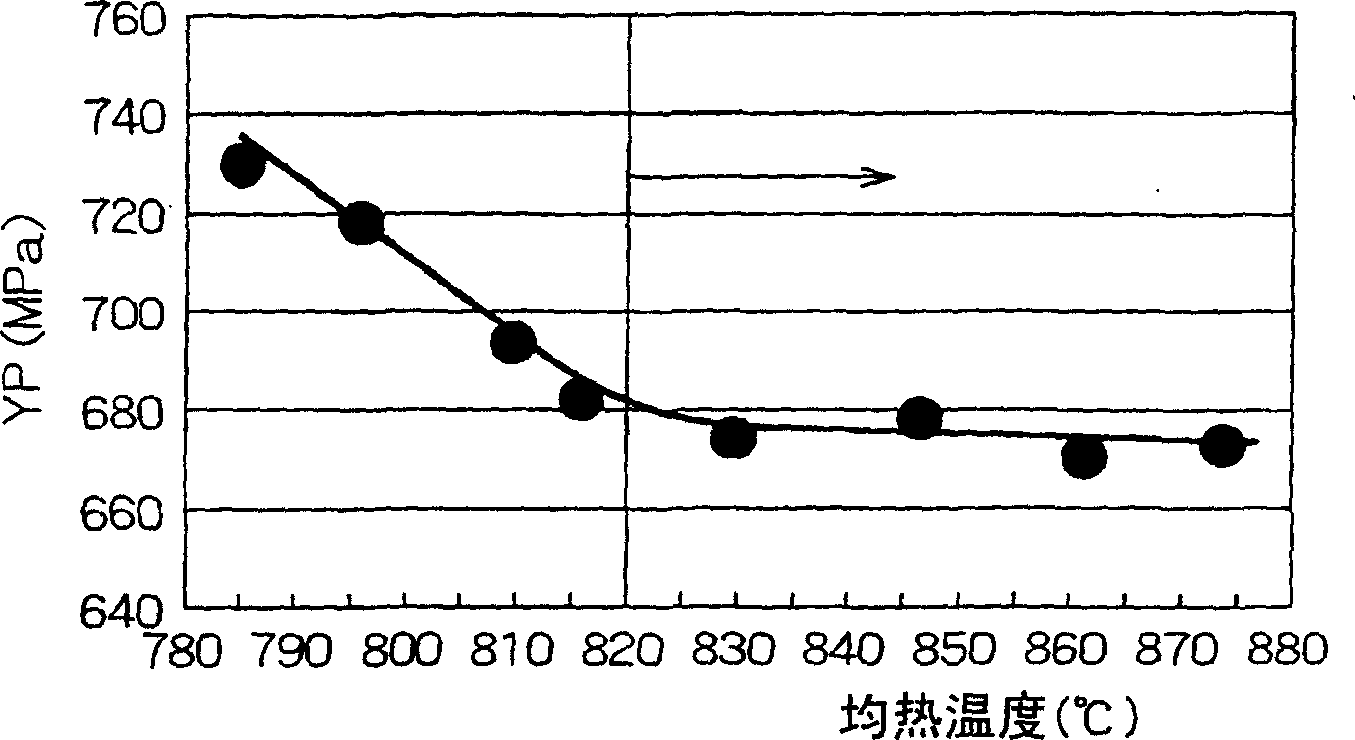

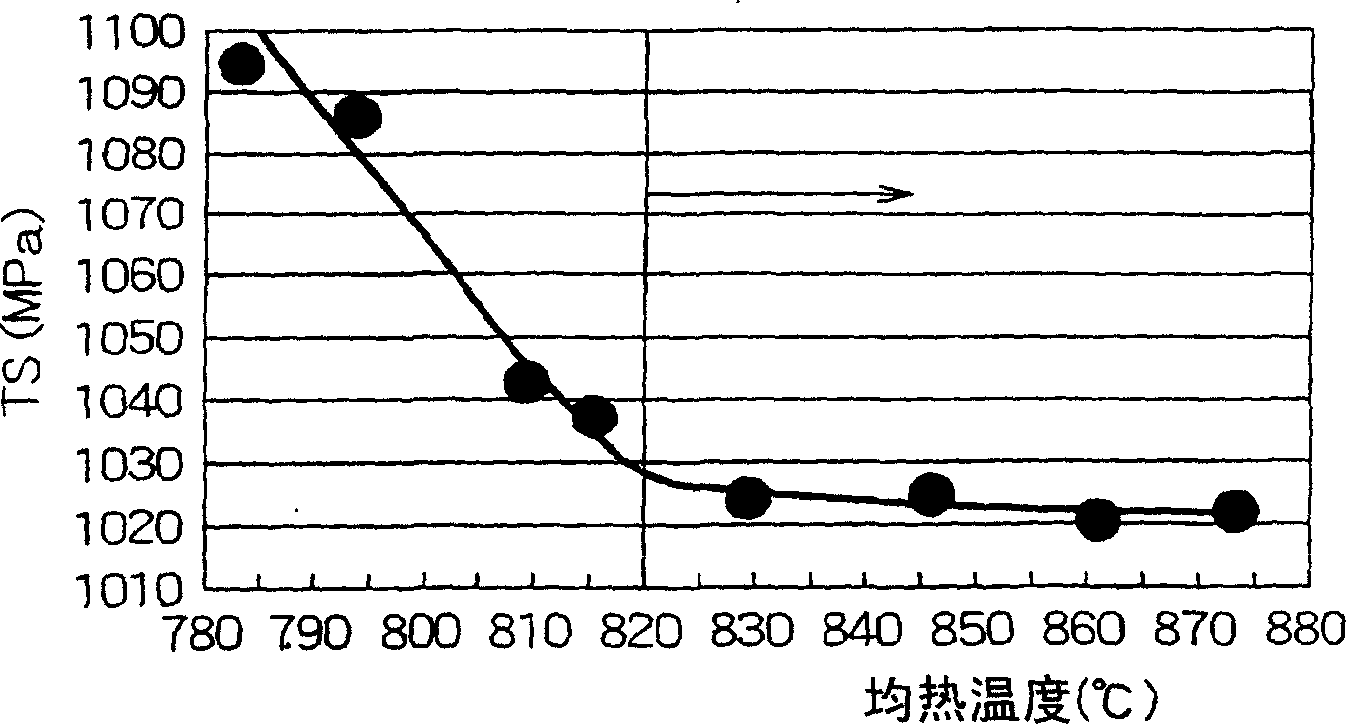

[0052] Each of A-O type steels having the chemical composition given in Table 1 was melted in a converter to form a 230 mm thick slab. Each of these samples was hot-rolled under the following conditions: a heating temperature of 1200°C; a finish rolling temperature of 850-900°C; and a coiling temperature of 510-600°C. As a result, a hot-rolled steel sheet having a thickness of 2.8 mm was obtained. Then, each hot-rolled steel sheet was pickled to remove surface scales, and then cold-rolled, thereby obtaining a 2.0 mm-thick cold-rolled steel sheet. As shown in Table 2, the cold-rolled steel sheets thus obtained were annealed under annealing (soaking) conditions, and then subjected to hot-dip galvanizing treatment (cooling and galvanizing) under hot-dip galvanizing conditions in order to obtain plated steel sheets with one side Hot-dip galvanized steel sheet (one side: 45g / m 2 ).

[0053] The strength (TS), yield strength (YP) and elongation (EL) of the steel sheet thus obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com