Image read device and vibration prevention device using same

An image reading device and image technology, applied in image communication, optics, instruments, etc., can solve the problems of high price of flywheel 17, increase of installation area, enlargement of the device, etc., achieve simple structure, prevent vibration, and reduce installation area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

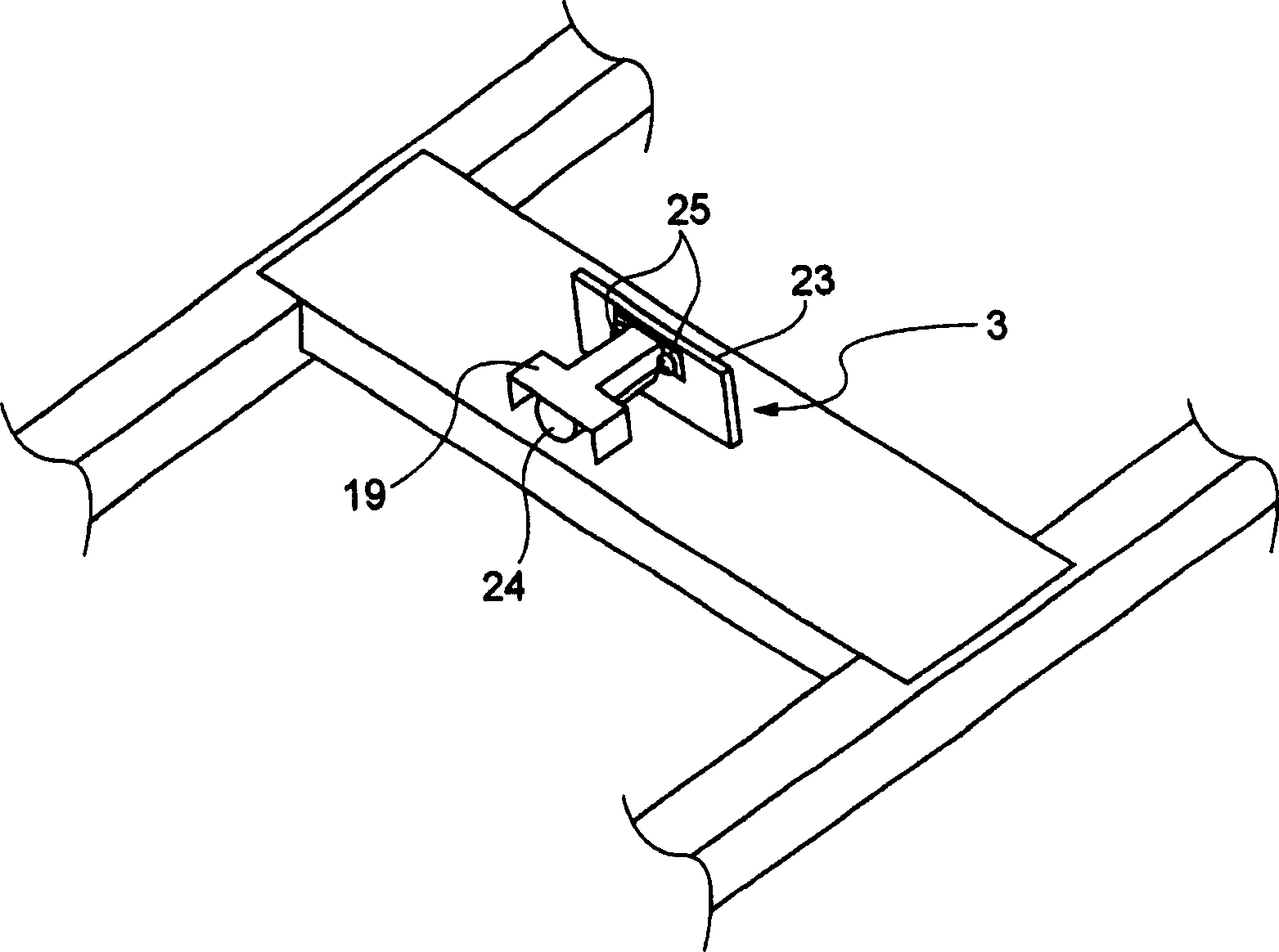

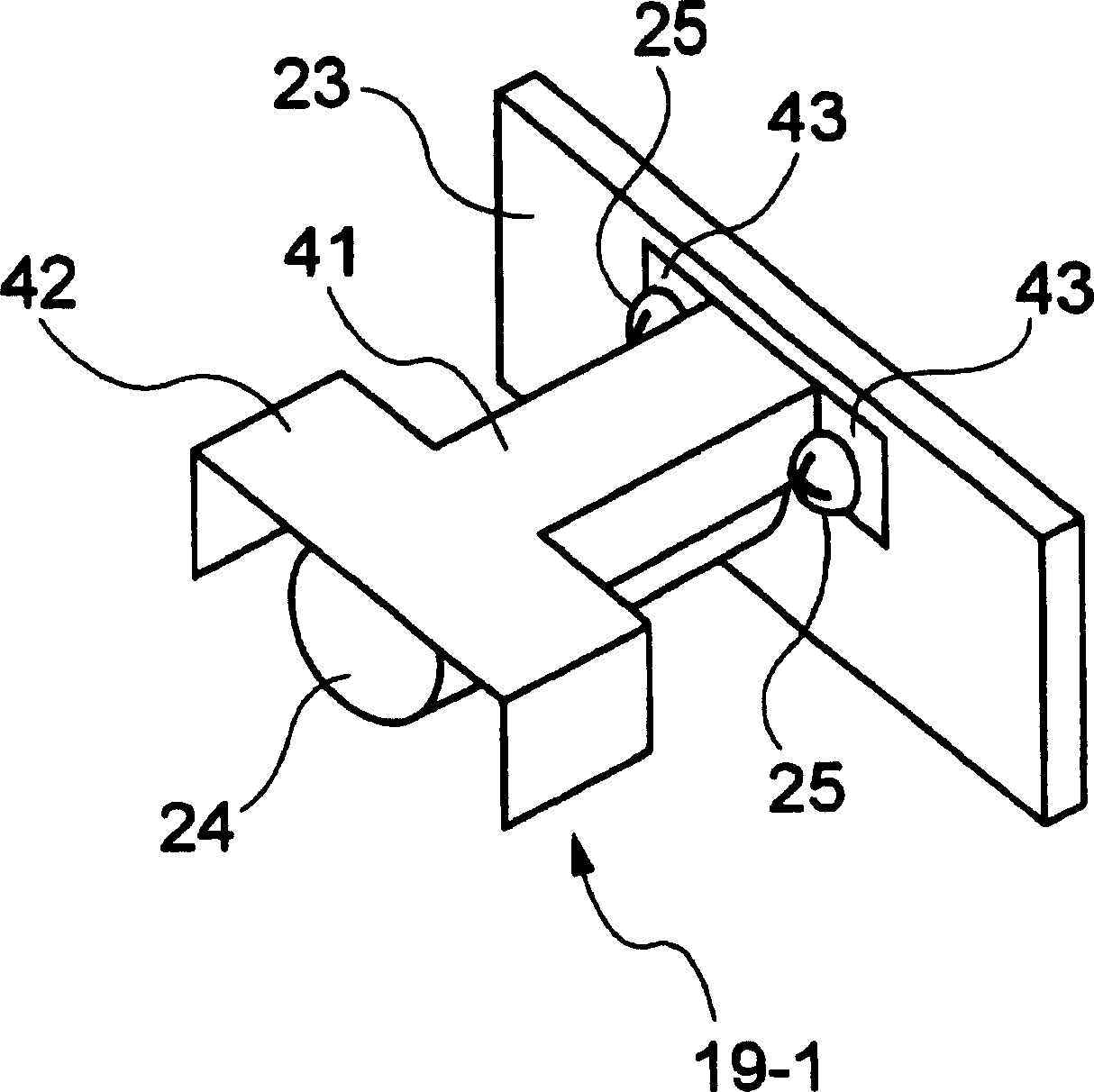

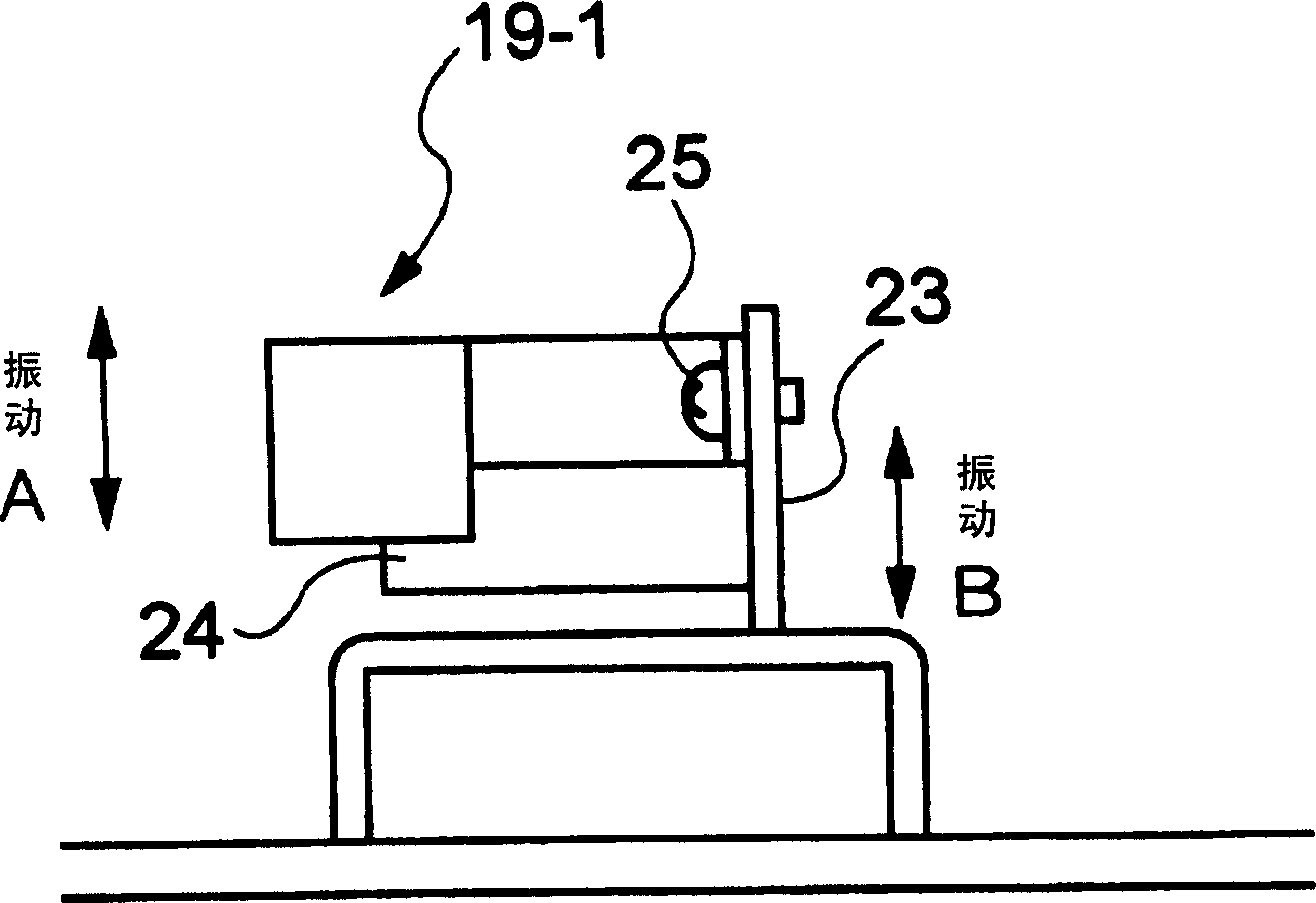

[0038] figure 2 It is a perspective view of the first embodiment of the anti-vibration device of the present invention. In addition, for this figure with figure 1 The same structural parts are given the same symbols, and therefore descriptions thereof are omitted. With reference to this figure, the weight 19-1 is composed of the following components: a first component 41, whose cross section is U-shaped; The first member 41 is wide; the third member 43 is provided at the other end of the first member 41 , and the first member 41 to the third member 43 are integrally formed.

[0039] However, it is also possible to use the first member 41 and the second member 42 as independent members, and adopt a mutually joined structure.

[0040] In addition, a hole (not shown) through which the screw 25 passes is formed in the third member 43 , and the weight 19 - 1 is attached to the CCD substrate 23 by the screw 25 through the hole. In addition, the installation position of the weigh...

Embodiment 2

[0045] Figure 4 It is a perspective view of the second embodiment of the anti-vibration device of the present invention. In addition, for this figure with figure 2 The same structural parts are given the same symbols, and therefore descriptions thereof are omitted. Referring to the figure, the weight 19-2 is different in shape from the weight 19-1 in the first embodiment in that the fourth member 44 corresponding to the second member 42 in the first embodiment is formed as a flat plate. Other shapes are the same as the first embodiment.

[0046] According to the second embodiment of the present invention, since the fourth member 44 does not need to be bent, the number of steps can be reduced.

[0047] (industrial availability)

[0048] In this embodiment, as the shape of the weight 19, figure 2 and Figure 4 An example is shown in , but it is not limited to these. As long as the following conditions are satisfied, the present invention can also be applied to the canti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com