Refrigerator of pulse tube

A pulse tube and refrigerator technology, applied in the direction of refrigerators, gas cycle refrigerators, compressors, etc., can solve the vibration of pulse tube refrigerators and other problems, and achieve the effect of suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

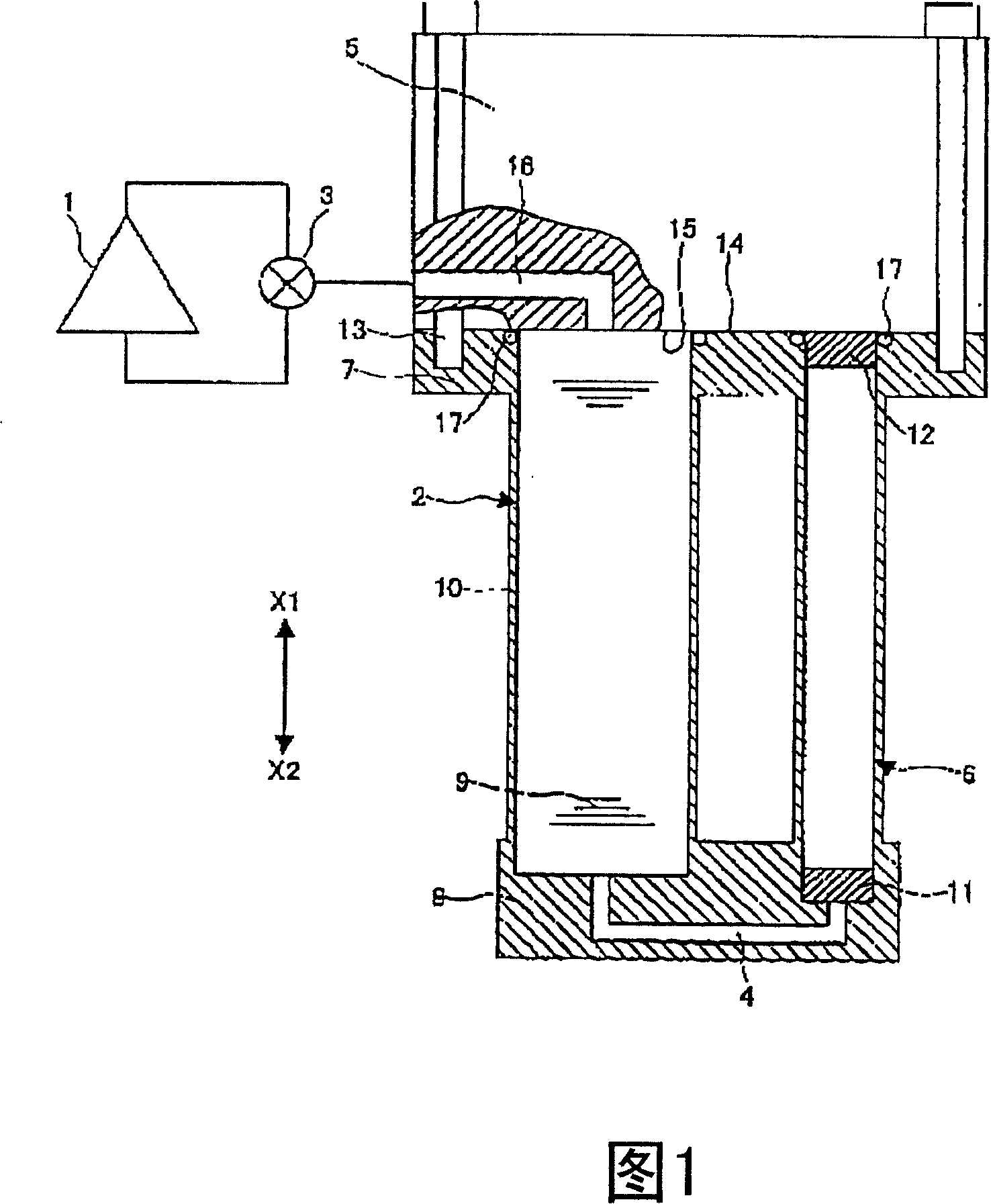

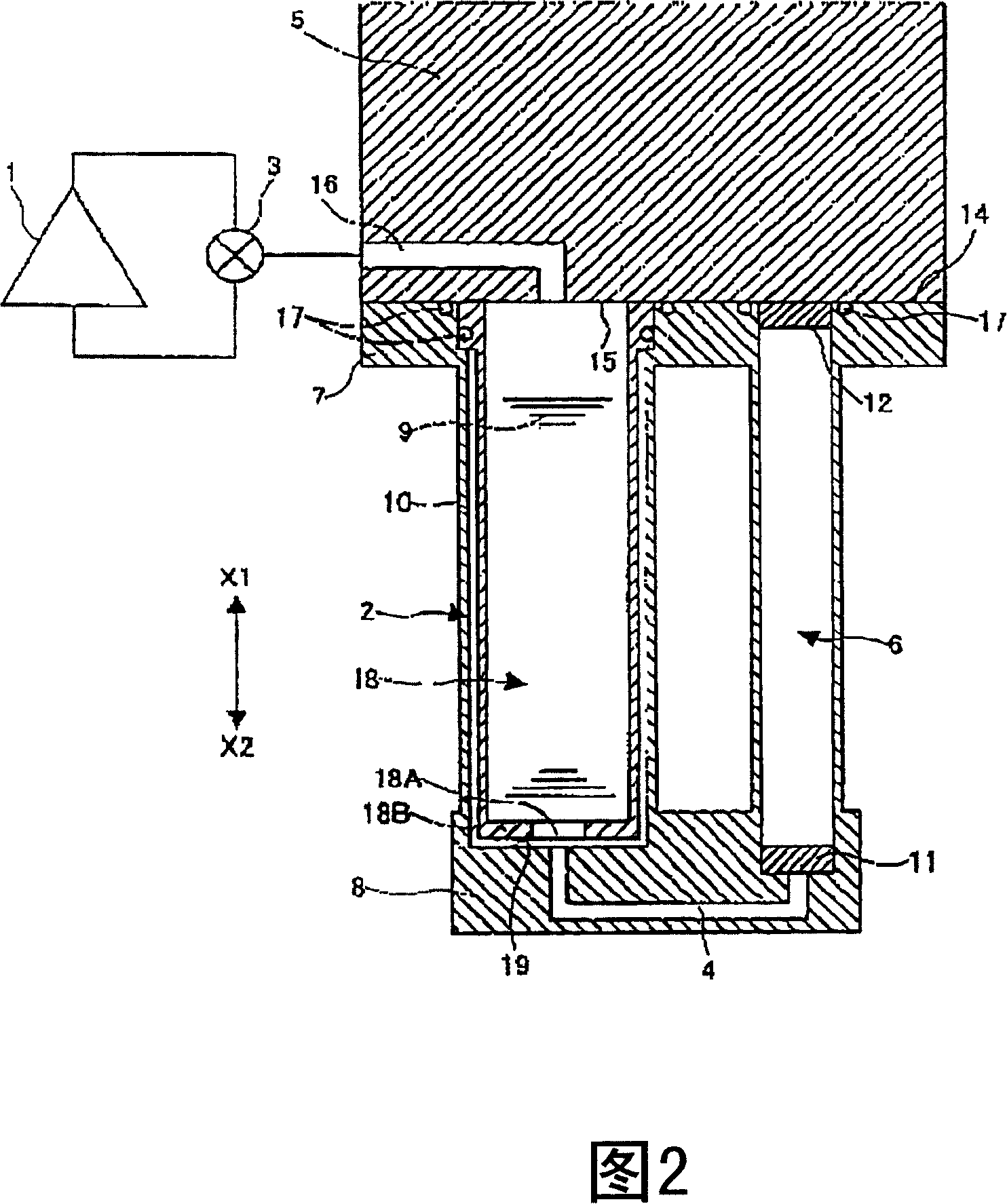

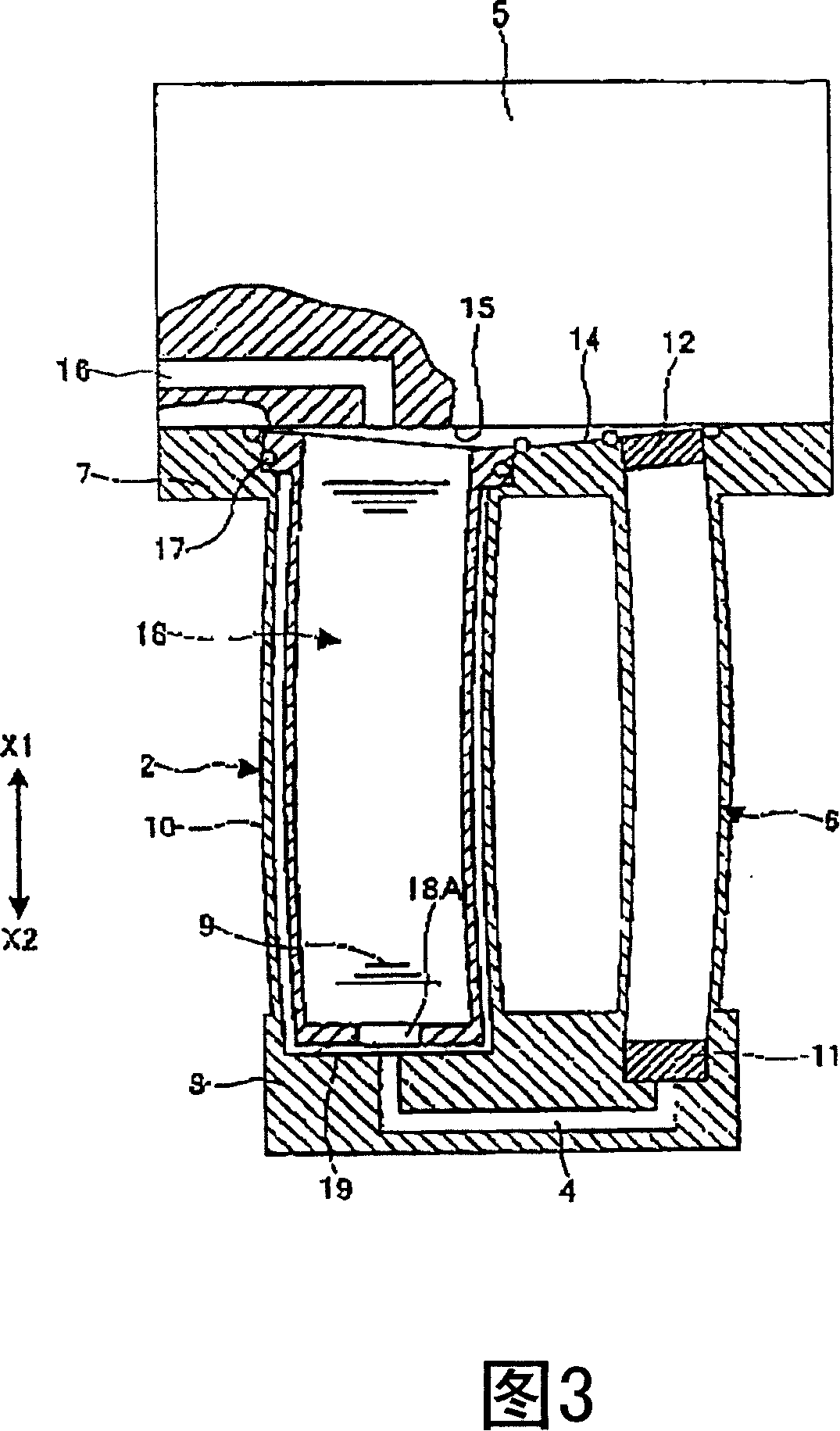

[0049] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings.

[0050] Fig. 5 is a configuration diagram of main parts of a pulse tube refrigerator 20A according to the first embodiment of the present invention. The pulse tube refrigerator 20A roughly includes a helium compressor 21, a regenerator 22, a switching valve 23, a phase adjustment mechanism 25, a pulse tube 26, a vacuum flange 27, a cooling table 28, a regenerator box 40, and the like.

[0051] The helium compressor 21 and the switching valve 23 function as a pressure vibration generator that generates pressure vibrations in the helium gas used as the working gas, and are connected to the high temperature end of the regenerator 22 through a pipe 36 formed in the phase adjusting mechanism 25 . The switching valve 23 performs a switching operation at a predetermined cycle, whereby the high-pressure helium gas generated by the helium compressor 21 is supplied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com