Electromagnetic apparatus and method for controlling fluid flow

A technology for controlling circuits and electromagnetic valves, which is applied in the direction of valve operation/release devices, valve devices, magnets, etc., and can solve problems such as armature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

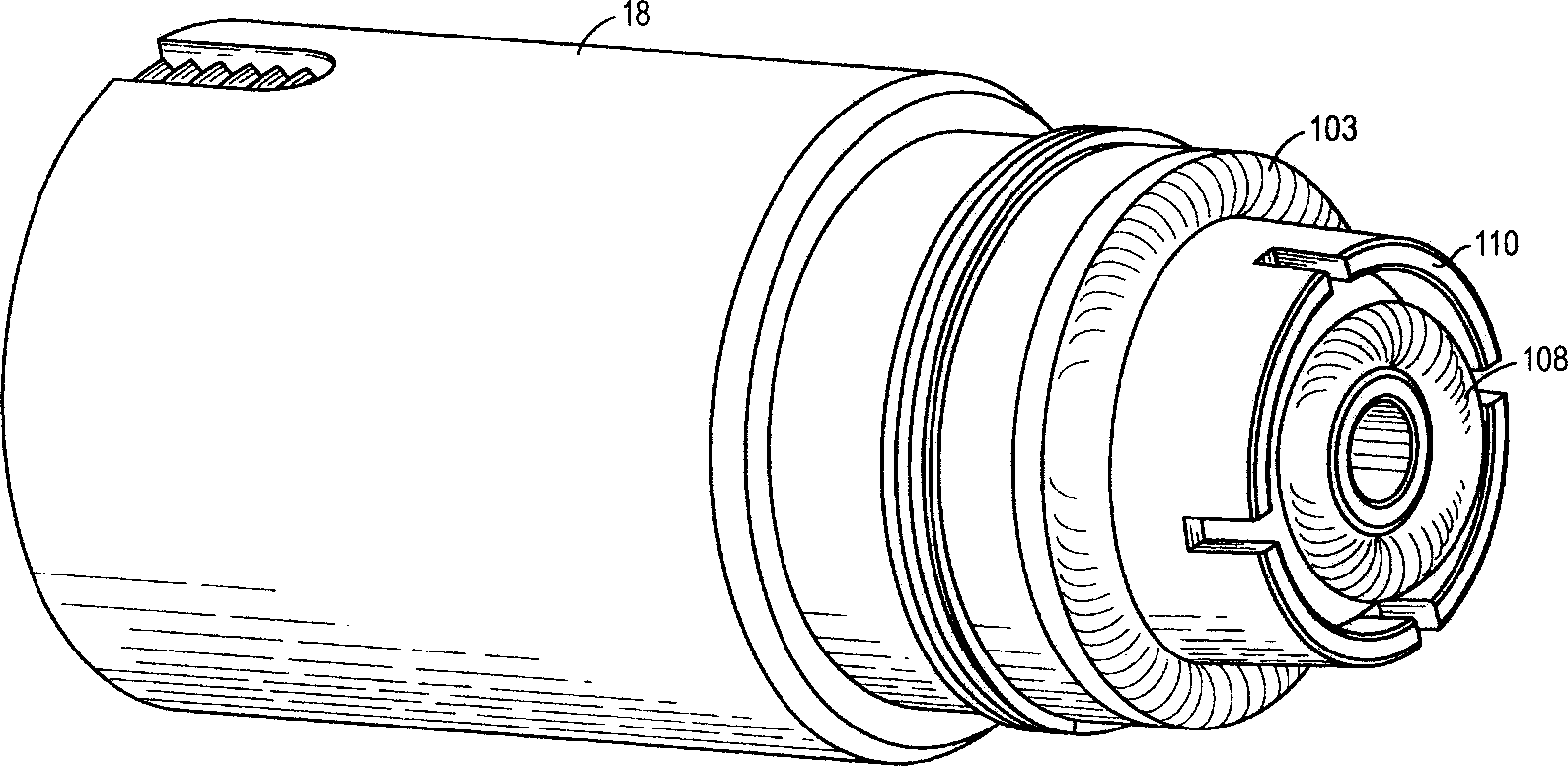

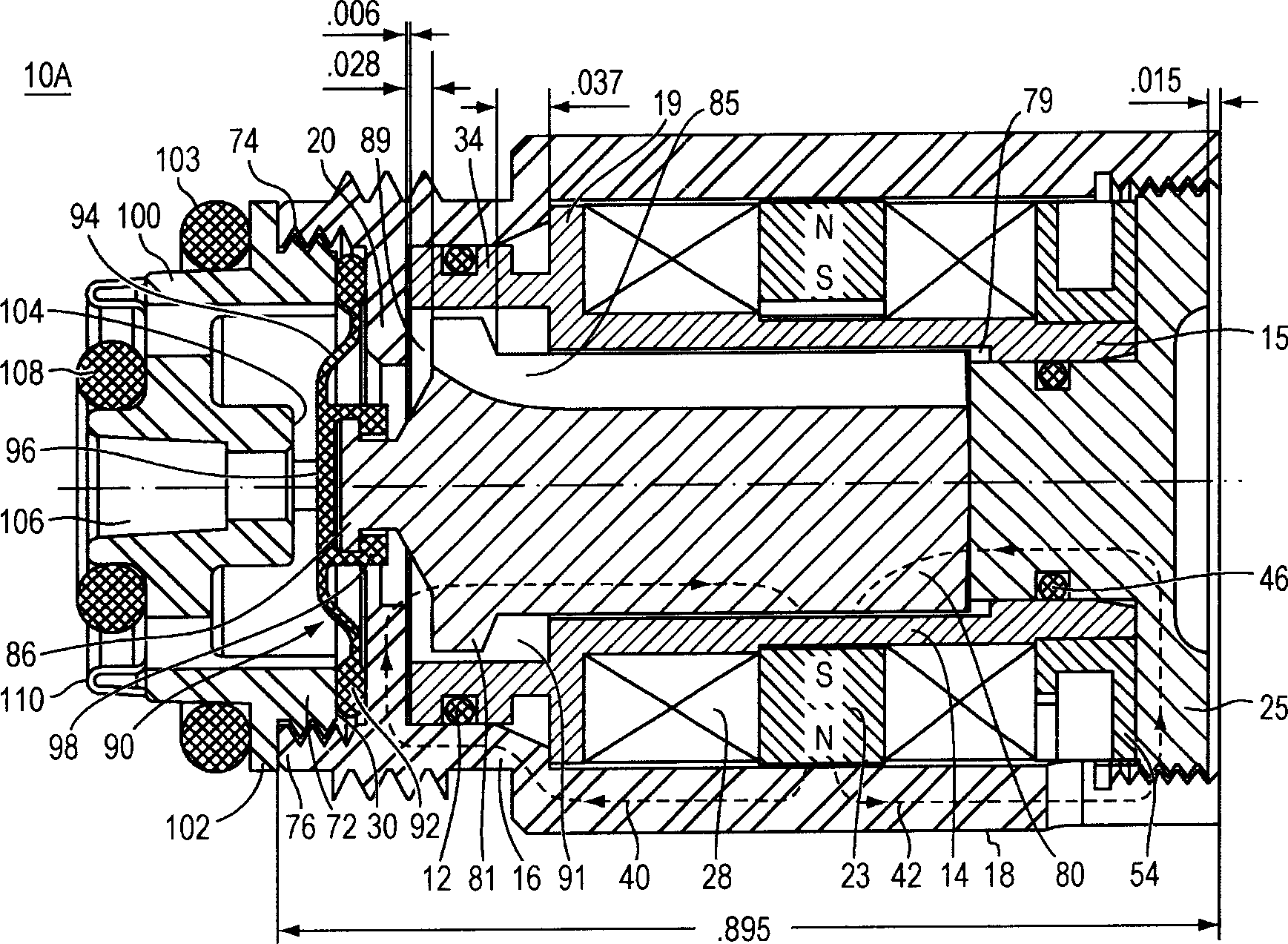

[0034] figure 1 and 2Shown is an electrically operable solenoid valve used in industrial, agricultural, and domestic systems for controlling the flow of fluids. The valve includes an electromagnetic actuator 10A that opens and closes a flow channel within the flow guide member 100 . Electromagnetic actuator 10A uses an electromagnetic field to move an armature disposed within the actuator longitudinally to and from the valve seat. The electromagnetic actuator 10A also uses the magnetic field from the radial magnets to hold the armature at the valve seat in an extended position or in a retracted position away from the valve seat, without affecting the actuator. apply any current.

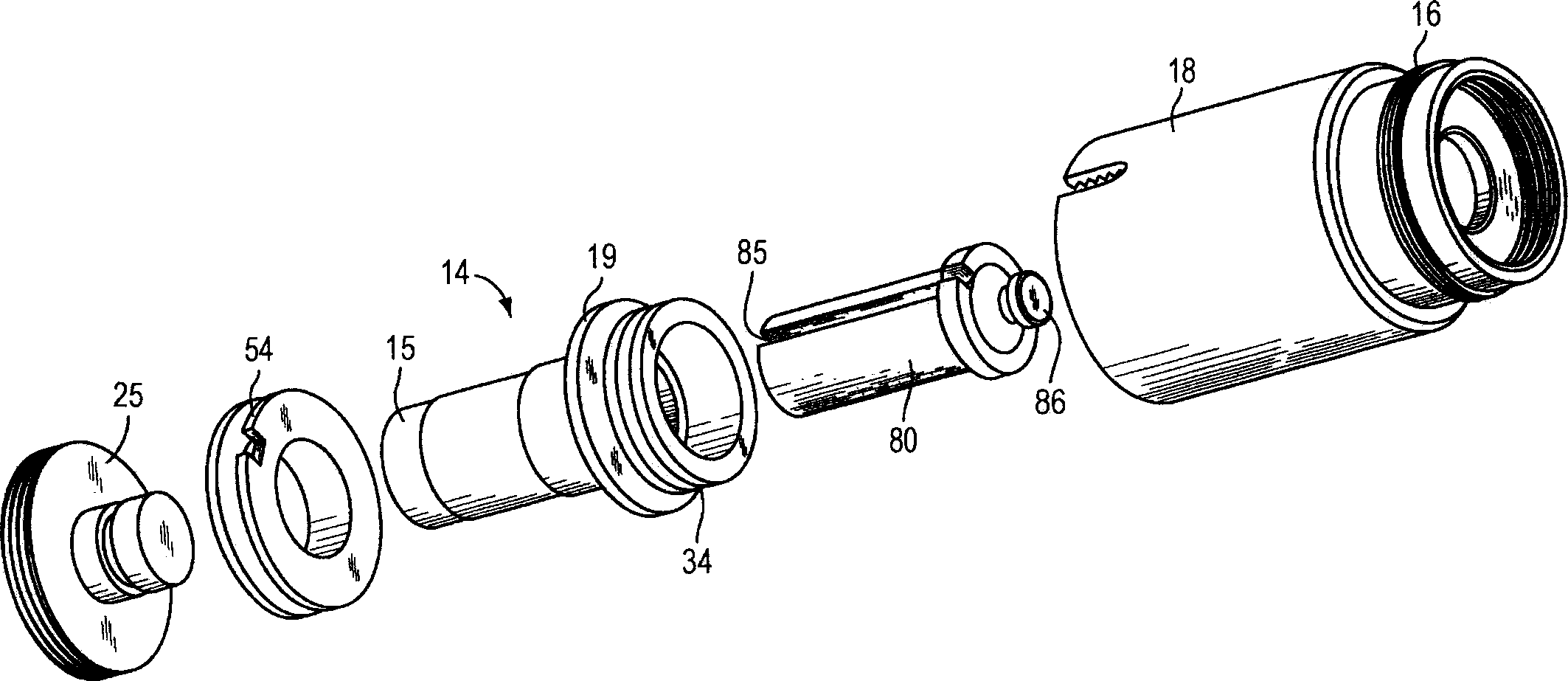

[0035] refer to figure 2 and image 3 , The electromagnetic actuator 10A includes a bobbin 14 , a cylindrical housing 18 , a rear pole piece 25 , a coil stopper 54 and an armature 80 . The armature 80 is placed within the cavity of the bobbin 14 which is placed within the cylindrical housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com