MEMS millimeter phase-shifter of low-exciting-voltage and precisie control

A technology of excitation voltage and precise control, applied in the field of phase shifters, can solve the problems of low phase precision and high excitation voltage, and achieve the effect of high phase shift control precision, low excitation voltage, and conducive to popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

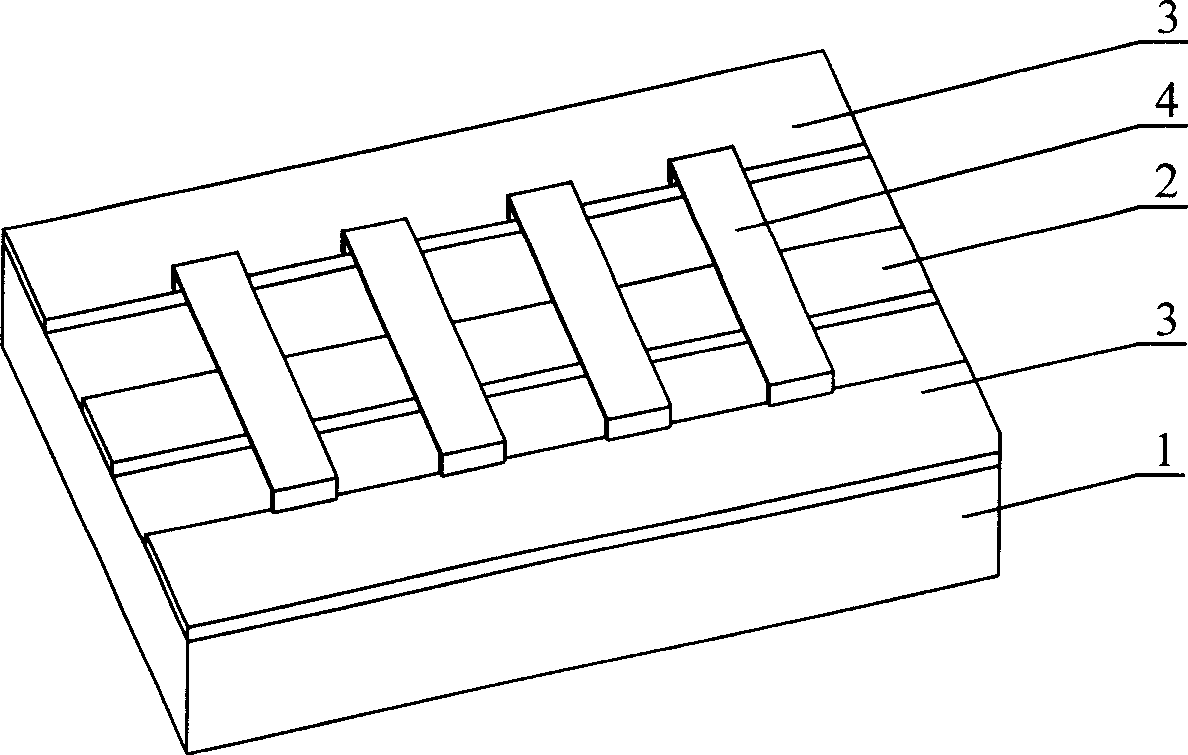

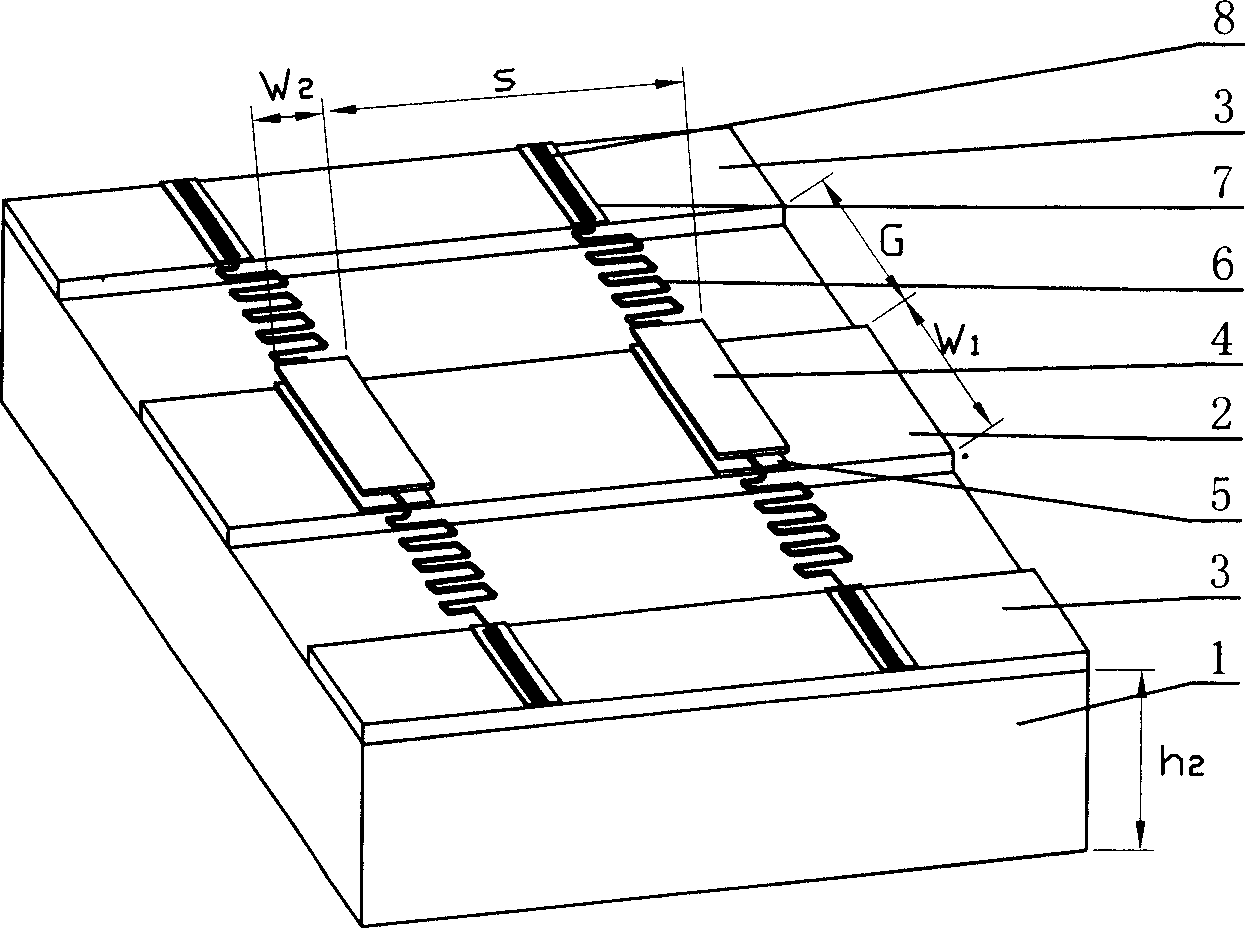

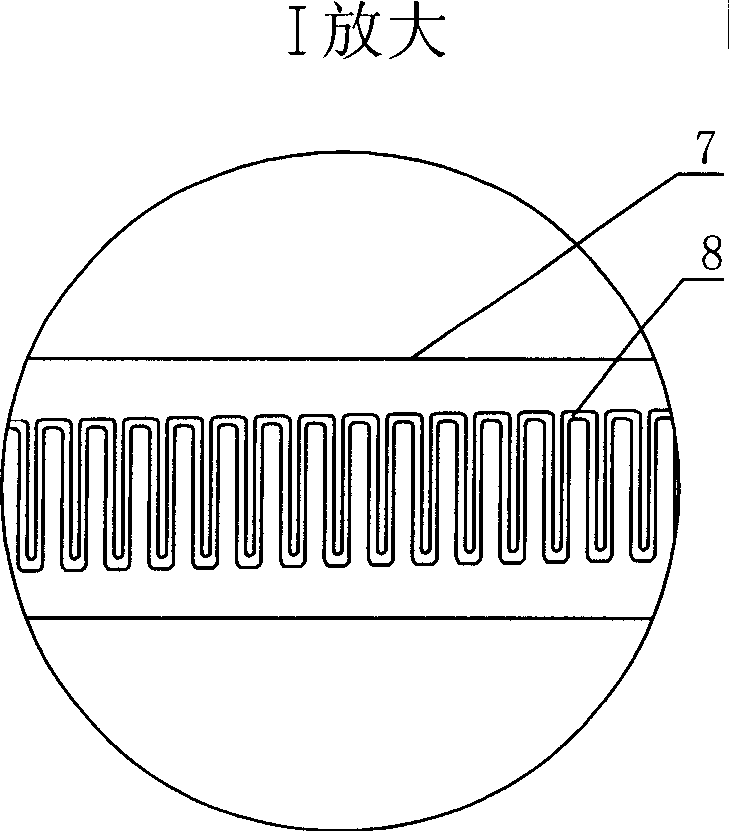

[0010] Specific implementation mode 1: This implementation mode is a MEMS millimeter wave phase shifter with low excitation voltage and precise control of phase shift characteristics, refer to Figure 2 ~ Figure 6 , it includes a bottom substrate 1, on which a signal line 2 and a ground line 3 are arranged at intervals, and it also includes a metal bridge 4 spanning directly above the signal line 2, and the ground line 3 is fixed with an inductance above 10nH The inductance coil 8 is provided with an insulating layer 7 between the inductance coil 8 and the ground wire 3, the inductance coil 8 is connected to one end of the metal spring 6, and the other end of the metal spring 6 is connected to the metal bridge 4 and carries out the metal bridge 4 support, the upper surface of the signal line 2 below the metal bridge 4 is provided with a dielectric constant ε r For: 2≤ε r ≤20 dielectric substrate 5.

[0011] This embodiment requires the inductance of the inductance coil 8 to ...

specific Embodiment approach 2

[0013] Embodiment 2: The difference from Embodiment 1 is that the dielectric substrate 5 selected in this embodiment is made of polyimide material, and the dielectric constant ε of polyimide is r =3.4, the thickness h of the dielectric substrate 5 1 It is 0.1 μm.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference from specific embodiment one is that this embodiment selects quartz as the dielectric substrate, and the dielectric constant ε of quartz r =3.78, the thickness h of the dielectric substrate 5 1 is 5 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com