Plasma treating coil

A plasma and coil technology, applied in the direction of plasma, discharge tube, electrical components, etc., can solve the problem of poor uniformity of edge plasma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Those of ordinary skill in the relevant technical field can also make various changes and modifications without departing from the spirit and scope of the present invention. Therefore All equivalent technical solutions also belong to the category of the present invention, and the scope of patent protection of the present invention should be defined by each claim.

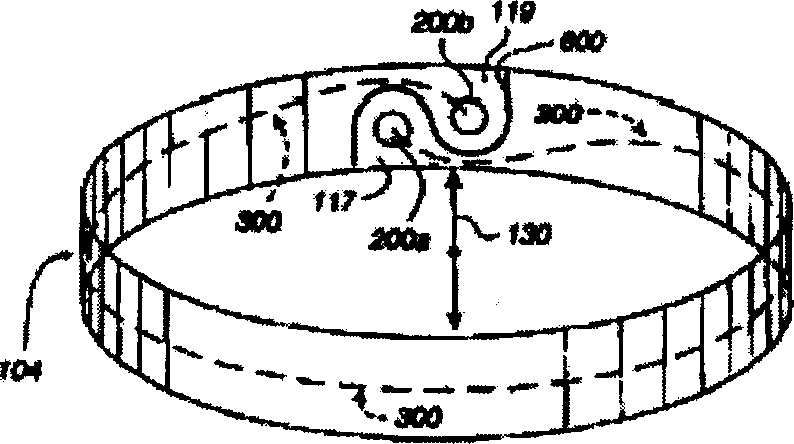

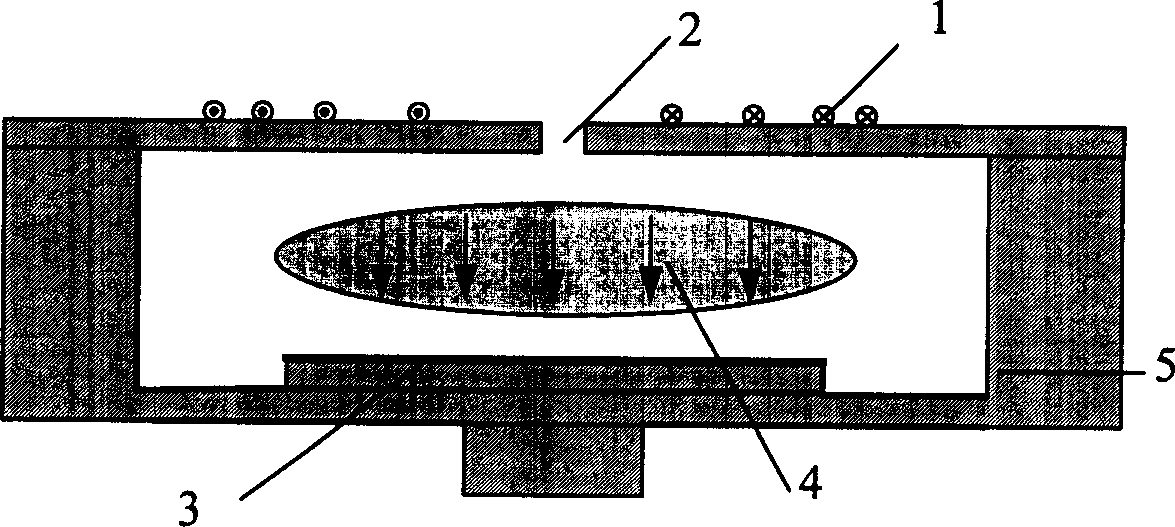

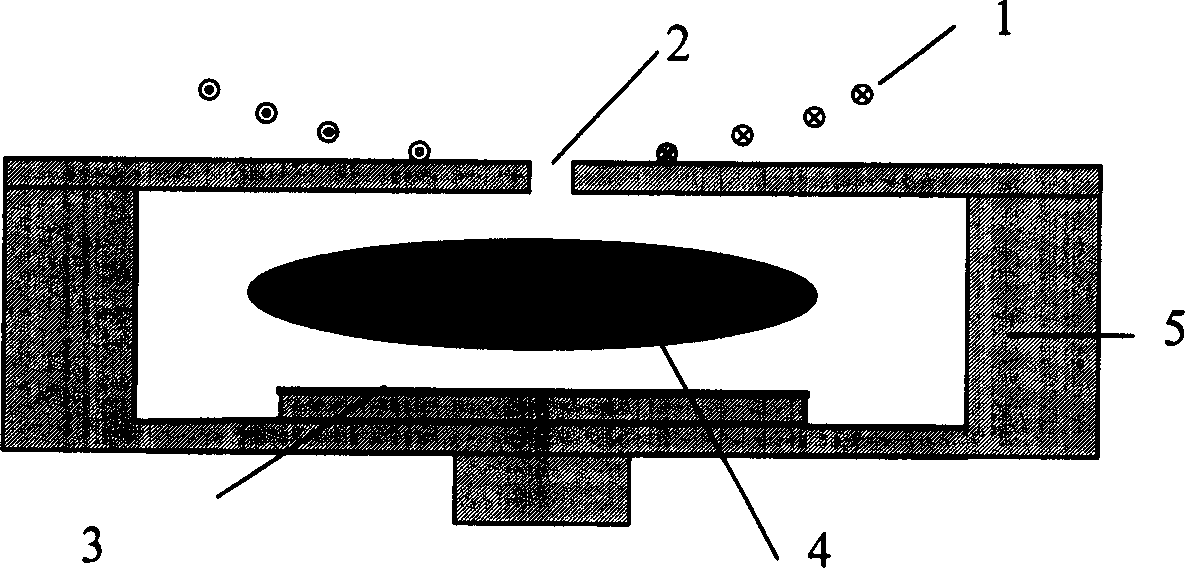

[0020] refer to image 3 , the plasma etching device coil of the present invention is a coil using a three-dimensional structure, and is installed on the upper cover of the reaction chamber 5 . Figure 4 This is the top view of the coil, the coil is composed of 4 turns, each turn is a circle with gaps in the same direction, these circles are on different planes, and the centers of these circles are all on the same axis, and finally connect each turn , the circle with larger d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com