Surface roughness and/ or contour shape measuring apparatus

A surface roughness and measuring device technology, applied in mechanical roughness/irregularity measurement, measuring device, mechanical counter/curvature measurement, etc., can solve problems affecting the accuracy of measurement, limited objects to be measured, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

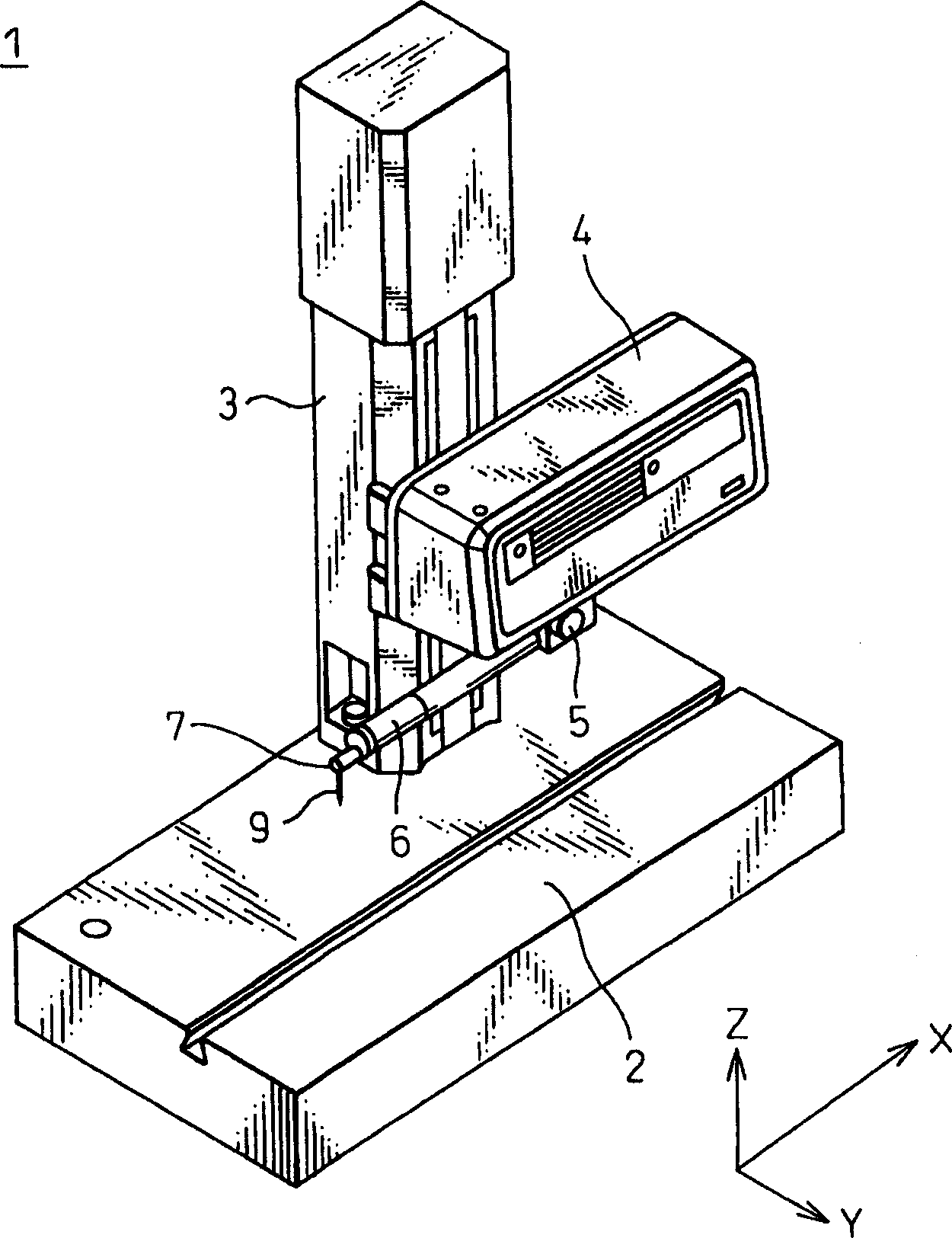

[0036] Figure 4 A basic configuration of a surface roughness and / or profile shape measuring device according to an embodiment of the present invention is shown. The basic structure of this surface roughness and / or profile shape measuring device 1 and figure 1 The shown configurations are similar, and the same functional components in these figures are respectively assigned the same reference numerals, and the explanation will not be repeated.

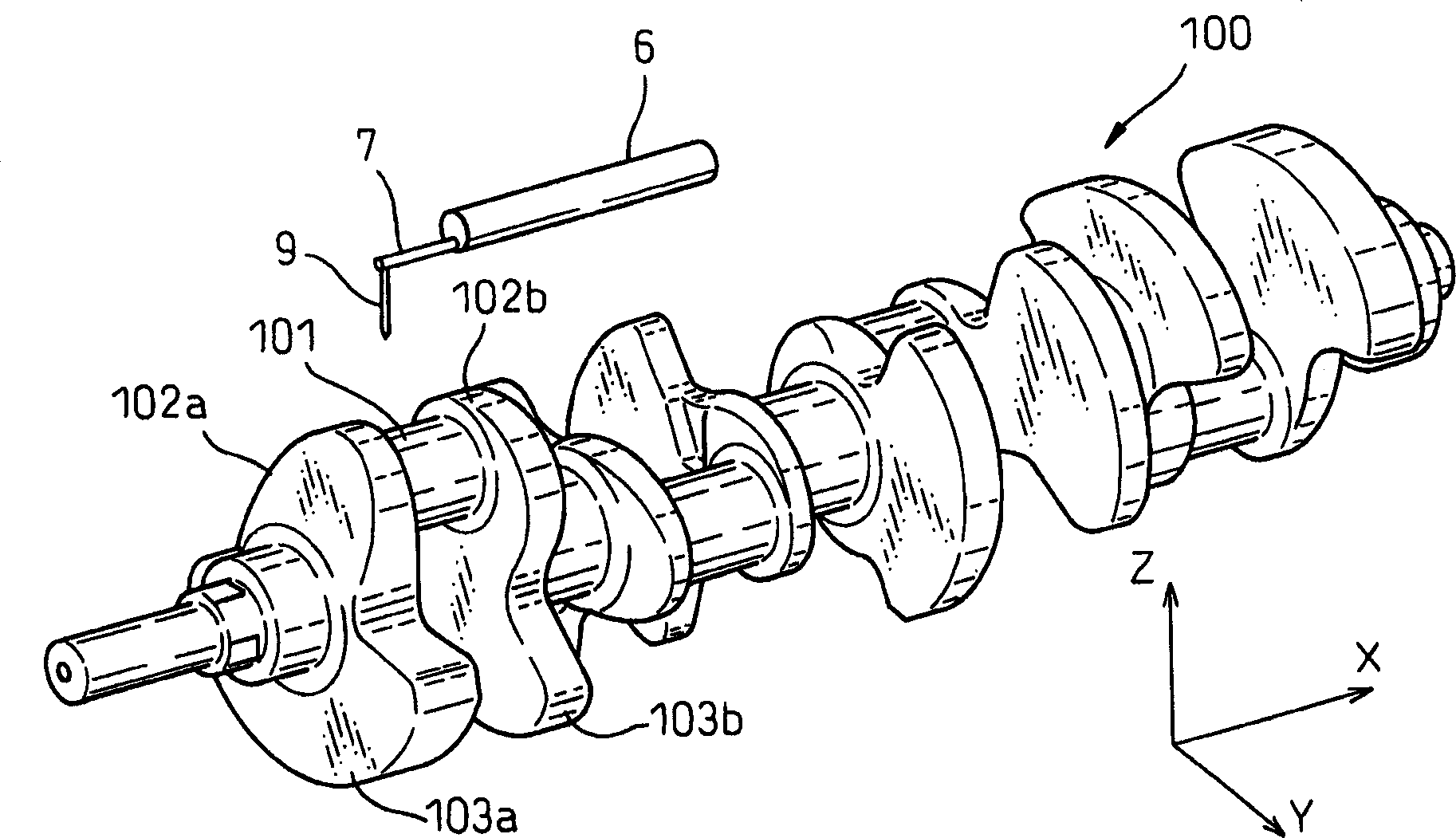

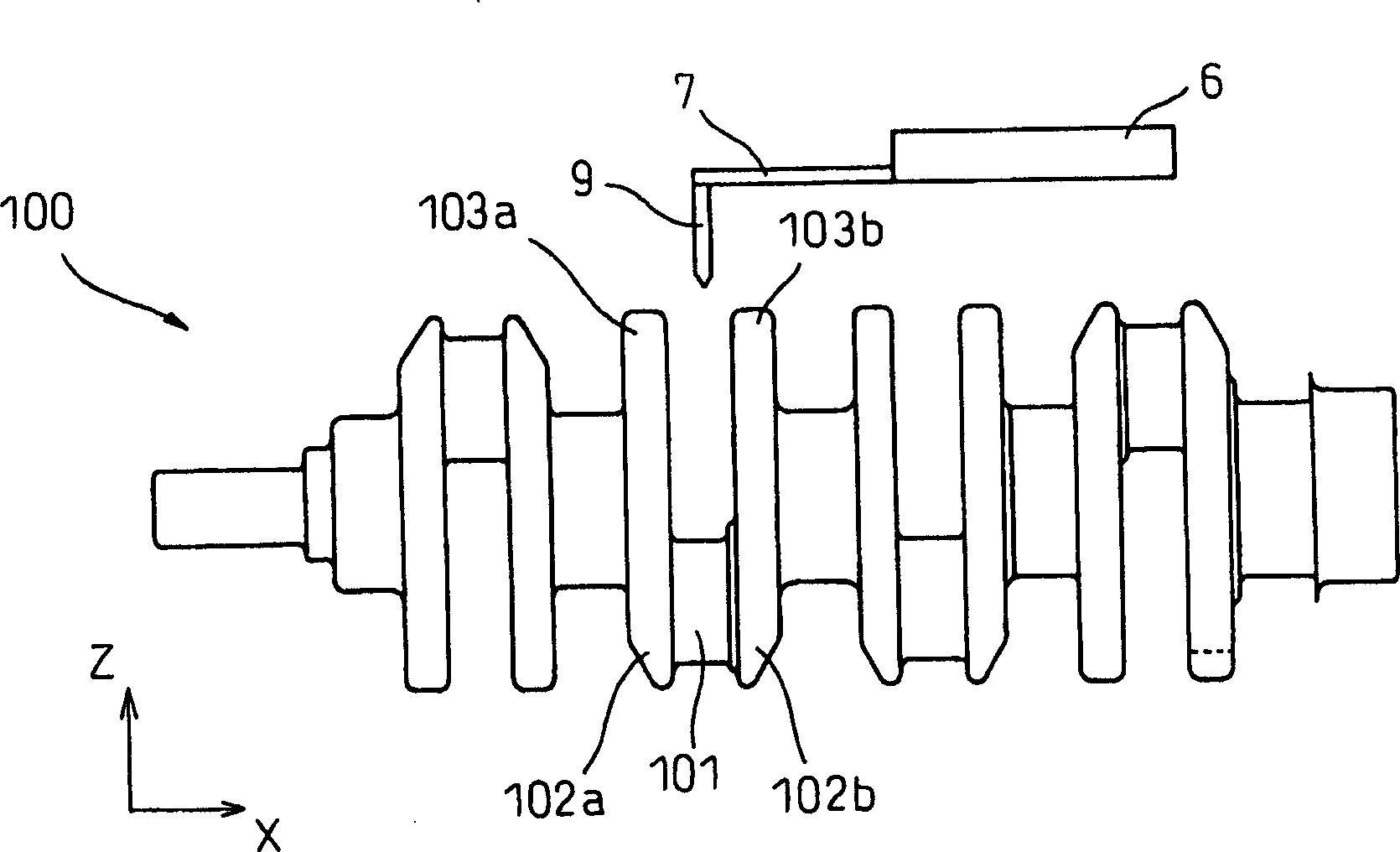

[0037] Such as Figure 4 As shown, in the surface roughness and / or profile shape measuring device 1, the pickup 6 and the cantilever 7 are installed so that their length direction is along the X direction, that is, the probe 9 is driven by the drive unit 4 on the table surface in the XY plane The direction of the drive. The probe 9 is mounted on the front end of the cantilever 7 so as to extend alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com