Motor lock

A technology of motor locks and micro-motors, applied in the field of motor locks, can solve problems such as damage to locks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

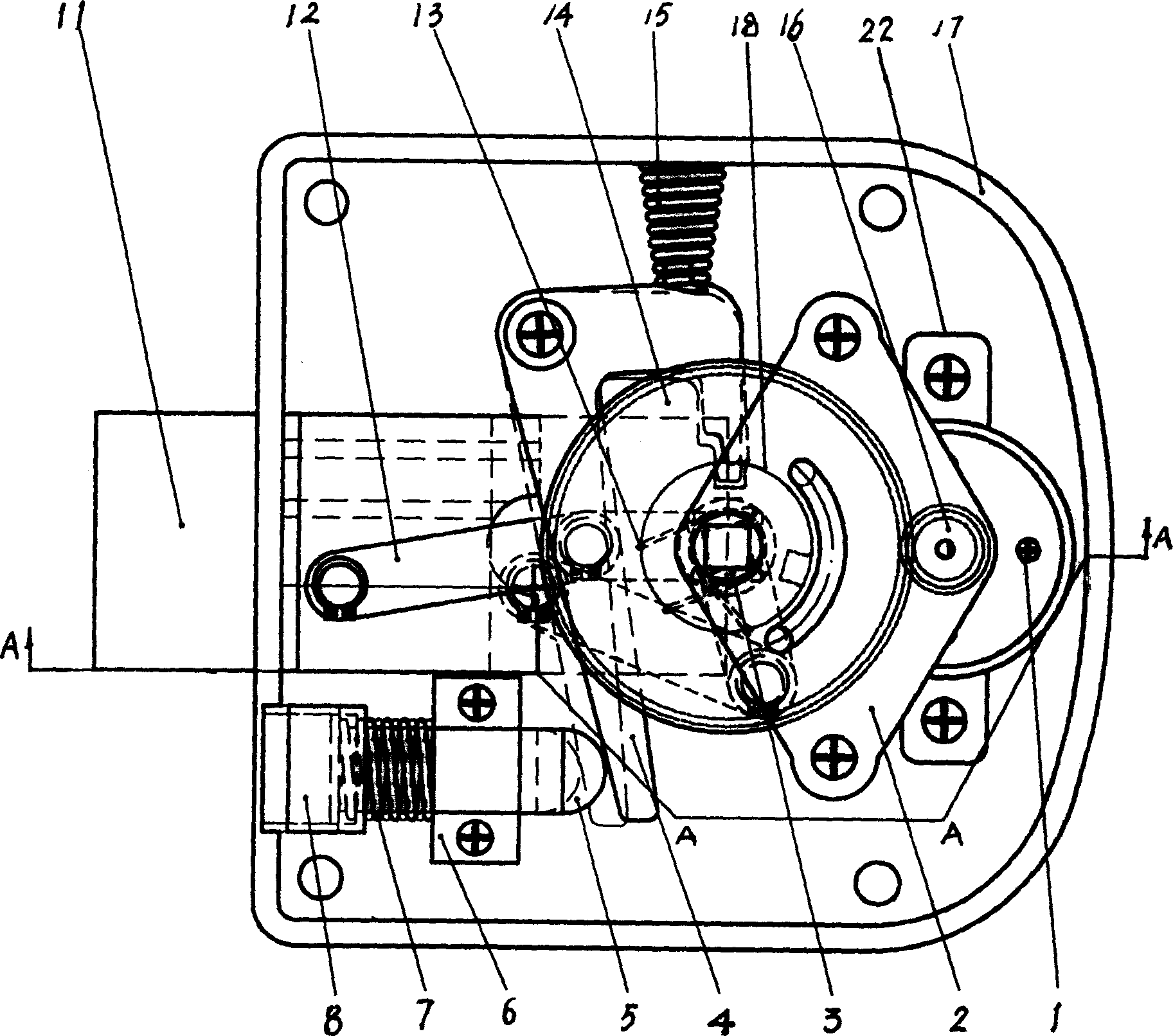

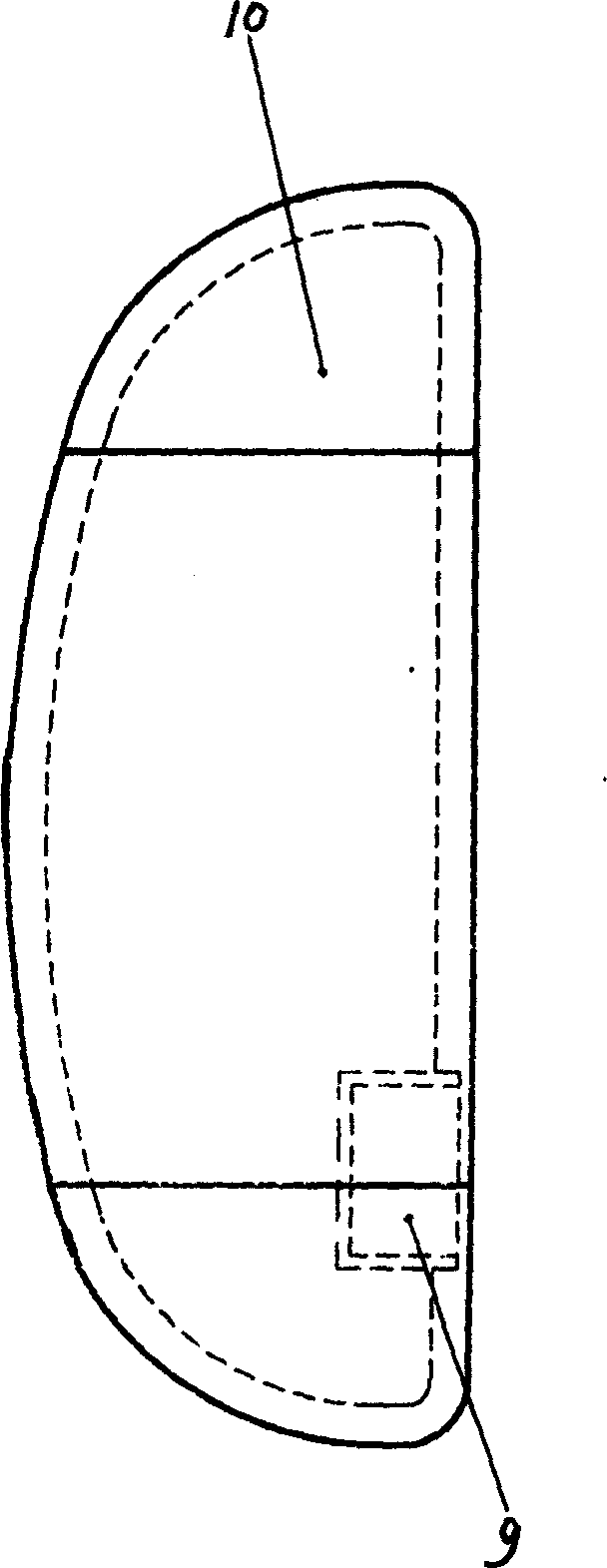

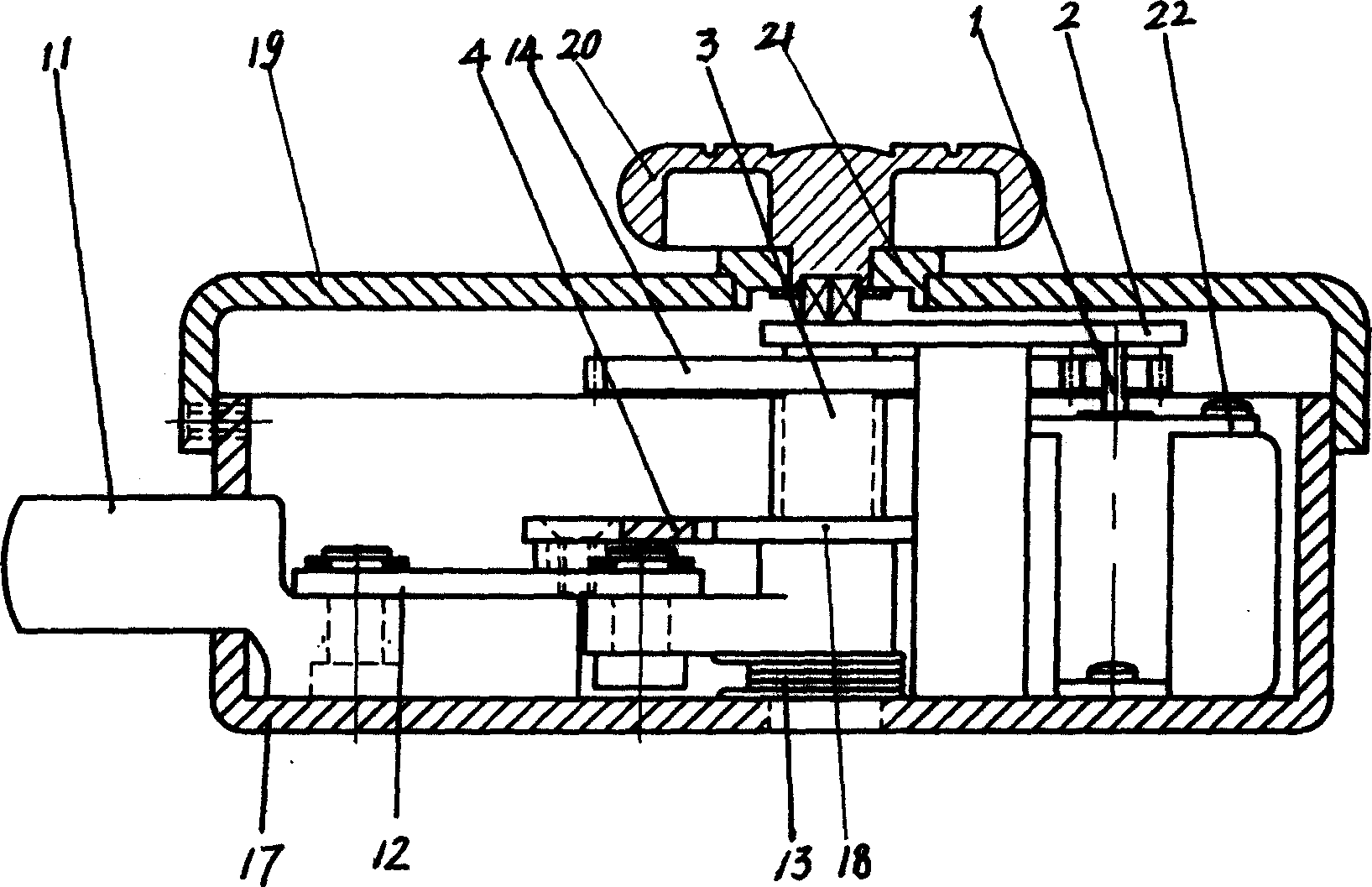

[0009] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0010] see Figure 1-Figure 3 , a kind of motor lock, including lock body and buckle 10, deadbolt 11, key, knob 20, micro-motor 1, lock body is constituted by main housing 17 and cover 19, and knob 20 passes through cover 19 and its shaft extends into the lock body, the micromotor 1 is installed in the main casing 17, the pinion 16 is installed on the extension shaft of the micromotor 1, the positioning plate 2 is fixed on the main casing 17, one end of the pulling rod rotating shaft 3 is sleeved in the main casing 17 and the other The positioning plate 2 fitted at one end can be rotated, the large gear 14 is set on the puller shaft 3, the large gear 14 meshes with the pinion 16, one end of the connecting rod 12 is connected with the puller shaft 3 and the other end is connected with the lock tongue 11, and the turntable 18 is set in the puller shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com