Method for preparing polyurethane acrylic resin

A technology of urethane acrylate and hydroxy acrylate, applied in the field of resin preparation, can solve the problems of instable HDI trimer structure, instable chain structure, low hardness of paint film, etc., and achieve good wear resistance and high hardness. , the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0009] The preparation method of the urethane acrylate resin provided by the invention comprises, in the presence of a catalyst, a solvent and a polymerization inhibitor, contacting an isocyanate trimer with a hydroxyacrylate, wherein the isocyanate trimer is selected from the group consisting of isophorone One or more in diisocyanate (IPDI) trimer, dicyclohexylmethane diisocyanate (HMDI) trimer, hexahydrotoluene diisocyanate (HTDI) trimer, preferably adopt isophorone diisocyanate ( IPDI) trimer.

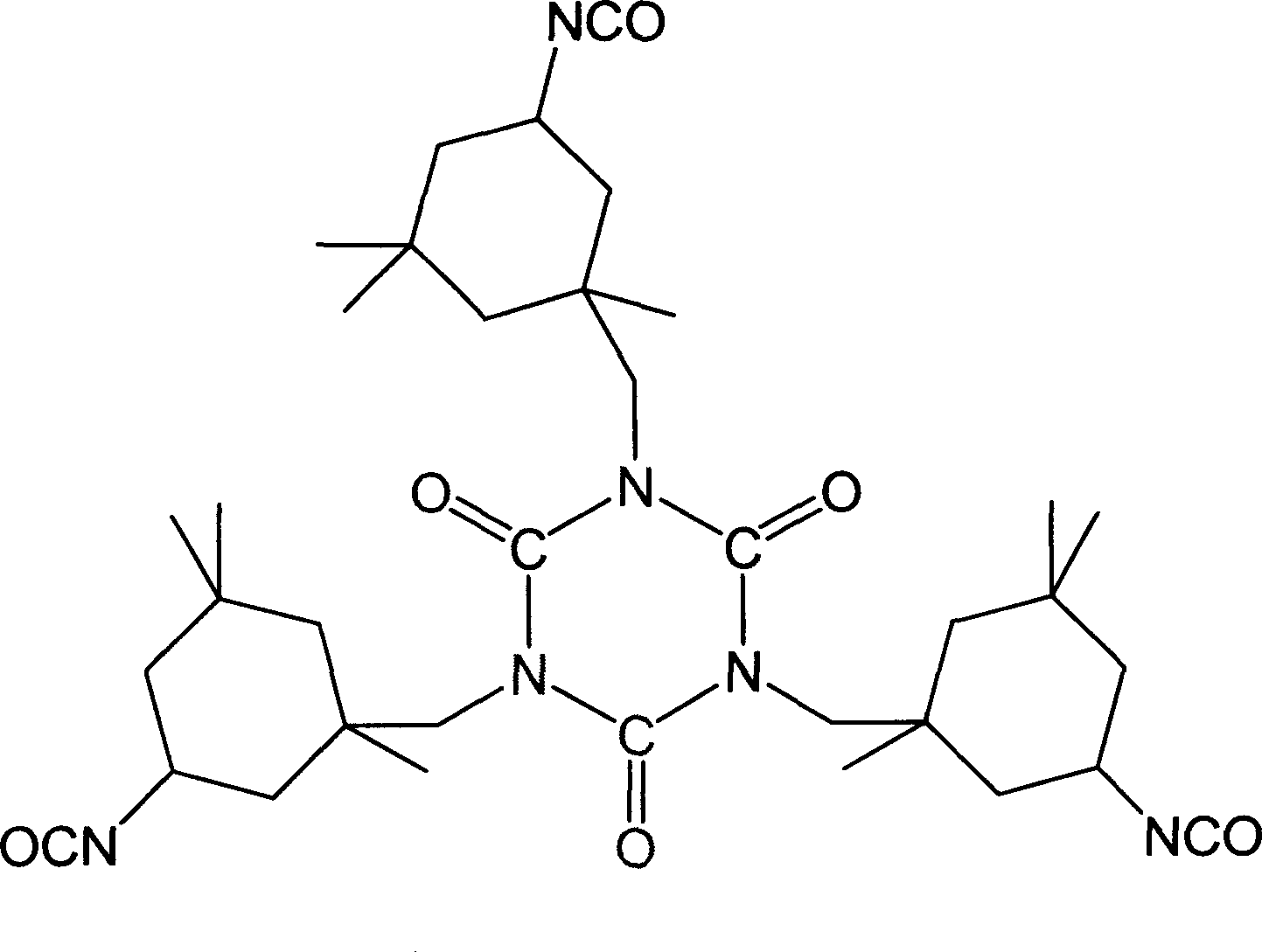

[0010] According to the present invention, described isophorone diisocyanate (IPDI) trimer has following chemical structural formula:

[0011]

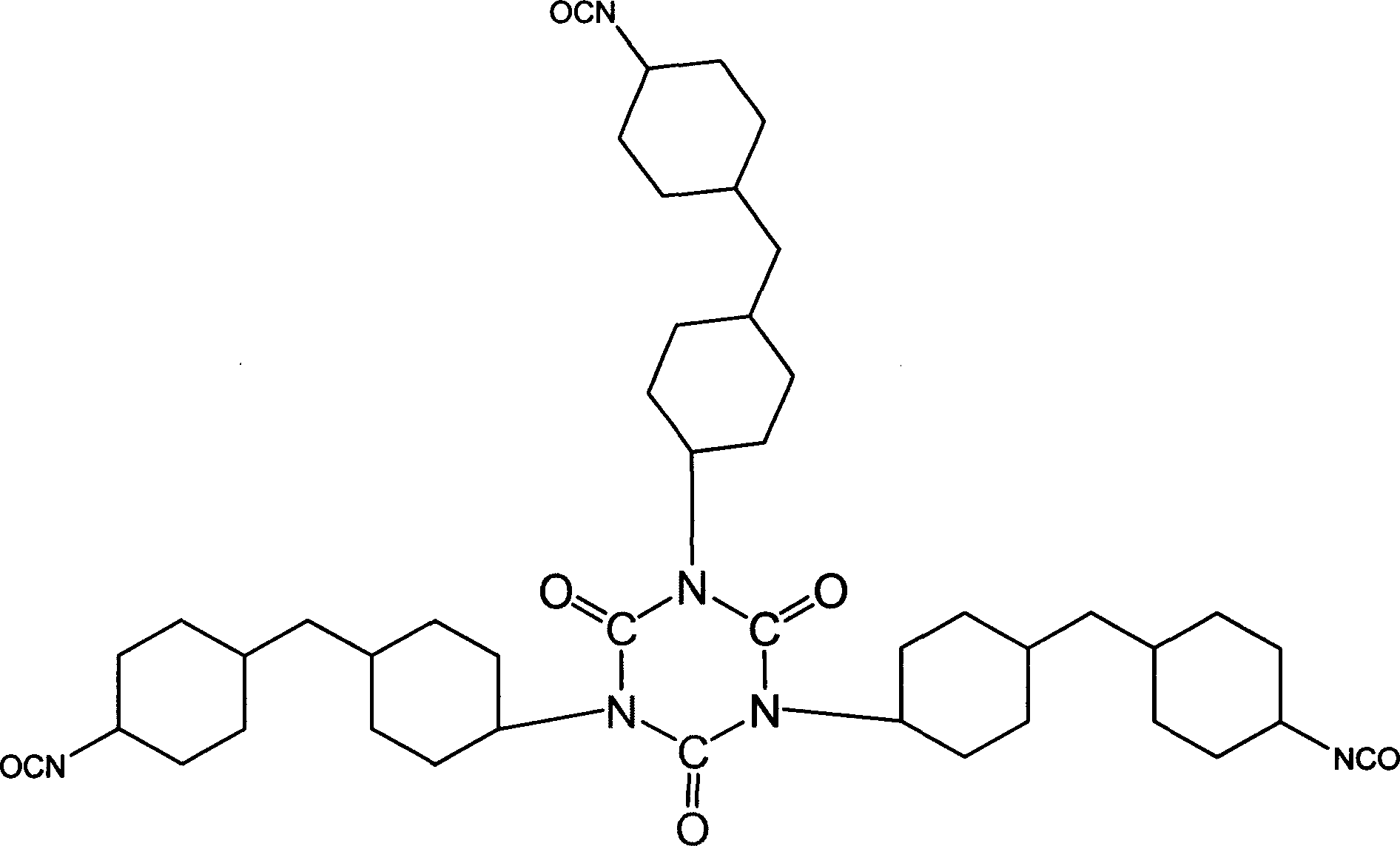

[0012] The dicyclohexylmethane diisocyanate (HMDI) trimer has the following chemical structural formula:

[0013]

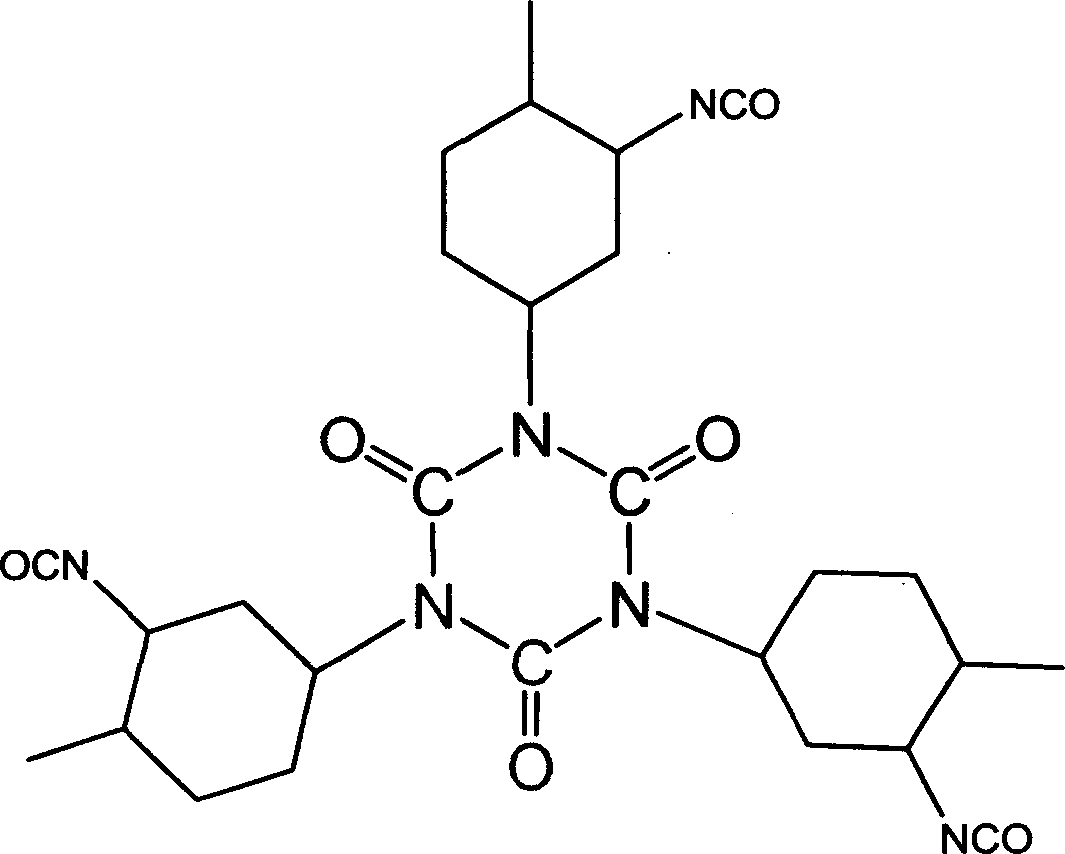

[0014] Described hexahydrotoluene diisocyanate (HTDI) trimer has following chemical structural formula:

[0015]

[0016] Toluene diisocyanate (TDI) can be 2, 6 isomers, 2, 4 isomers or their mixtures, and industria...

Embodiment 1

[0028] This example illustrates the preparation of polyurethane acrylate resin

[0029] Add 200 g of butyl acetate solution containing 70% isophorone diisocyanate trimer into the reaction flask, preheat at 45° C. for 10 minutes, and stir. Then the solution formed by dissolving 84.7 grams of hydroxyethyl methacrylate, 0.05 grams of dibutyltin dilaurate, and 0.02 grams of p-methoxyphenol in 30 grams of butyl acetate is slowly added to the reaction flask. The reaction temperature was increased to 65° C., and the reaction was maintained at this temperature for 4 hours to obtain polyurethane acrylate resin S1.

Embodiment 2

[0034] This example illustrates the preparation of polyurethane acrylate resin

[0035] Add 200 g of butyl acetate solution containing 70% isophorone diisocyanate trimer into the reaction flask, preheat at 45° C. for 10 minutes, and stir. Then the solution formed by dissolving 83.5 grams of hydroxyethyl methacrylate, 0.1 gram of dibutyltin dilaurate, and 0.025 gram of p-methoxyphenol in 35 grams of butyl acetate is slowly added to the reaction flask. The reaction temperature was increased to 65° C., and the temperature was maintained for 4 hours to obtain polyurethane acrylate resin S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com