Pressure transducer provided with a piezoelectric element for the detection of errors in separation membranes

A measurement converter and electrical measurement technology, applied in the direction of measuring fluid pressure through electromagnetic components, measuring devices, measuring fluid pressure, etc., can solve problems such as hindering pressure and wrong measurement, and achieve reliable judgment and reliable measurement values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

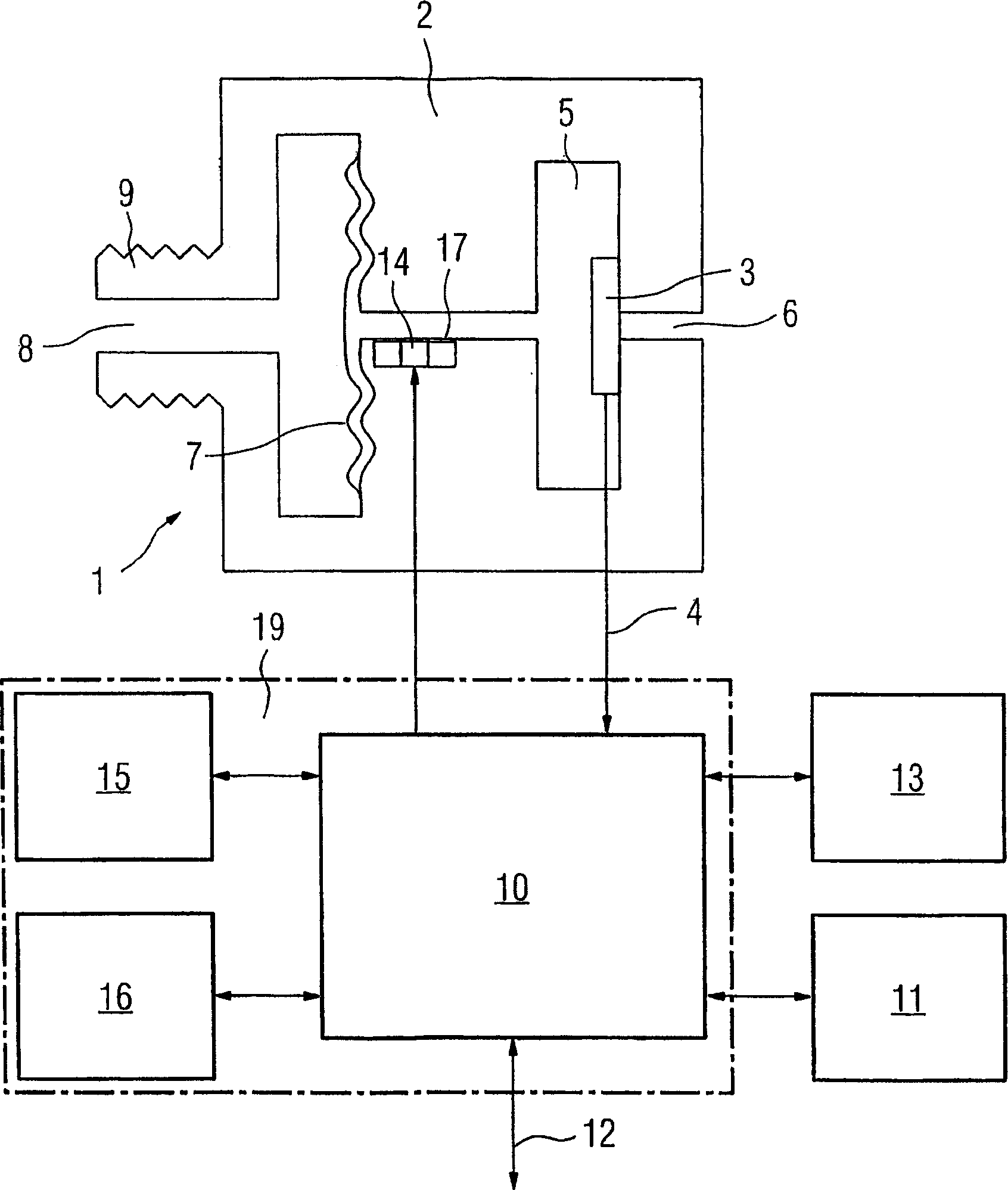

[0015] figure 1 The circuit block diagram of the pressure measurement transducer is shown. The pressure measuring transducer has an essentially rotationally symmetrical measuring cell 1 with a housing 2 in which a pressure sensor 3 is arranged for converting the pressure to be measured into an electrical measuring signal 4 . The pressure sensor 3 is located between the measuring chamber 5 and the channel 6 for introducing a reference pressure. The measuring chamber 5 is filled with silicone oil as a pressure transmitting liquid. Air is led through channel 6 to pressure sensor 3 at the prevailing ambient pressure. In the embodiment shown, measurement signal 4 thus reproduces an absolute pressure which is dependent on the ambient pressure. To protect the sensor, the pressure-transmitting liquid is separated in the measuring chamber by a diaphragm 7 from the process medium 8 , which is introduced into the pressure-measuring cell 1 through a channel at the pressure to be measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com