Epitaxial structure for vertical cavity emitting semiconductor laser diode

A technology of vertical cavity surface emission and laser diodes, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., to achieve the effects of good stability, high repeatability, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

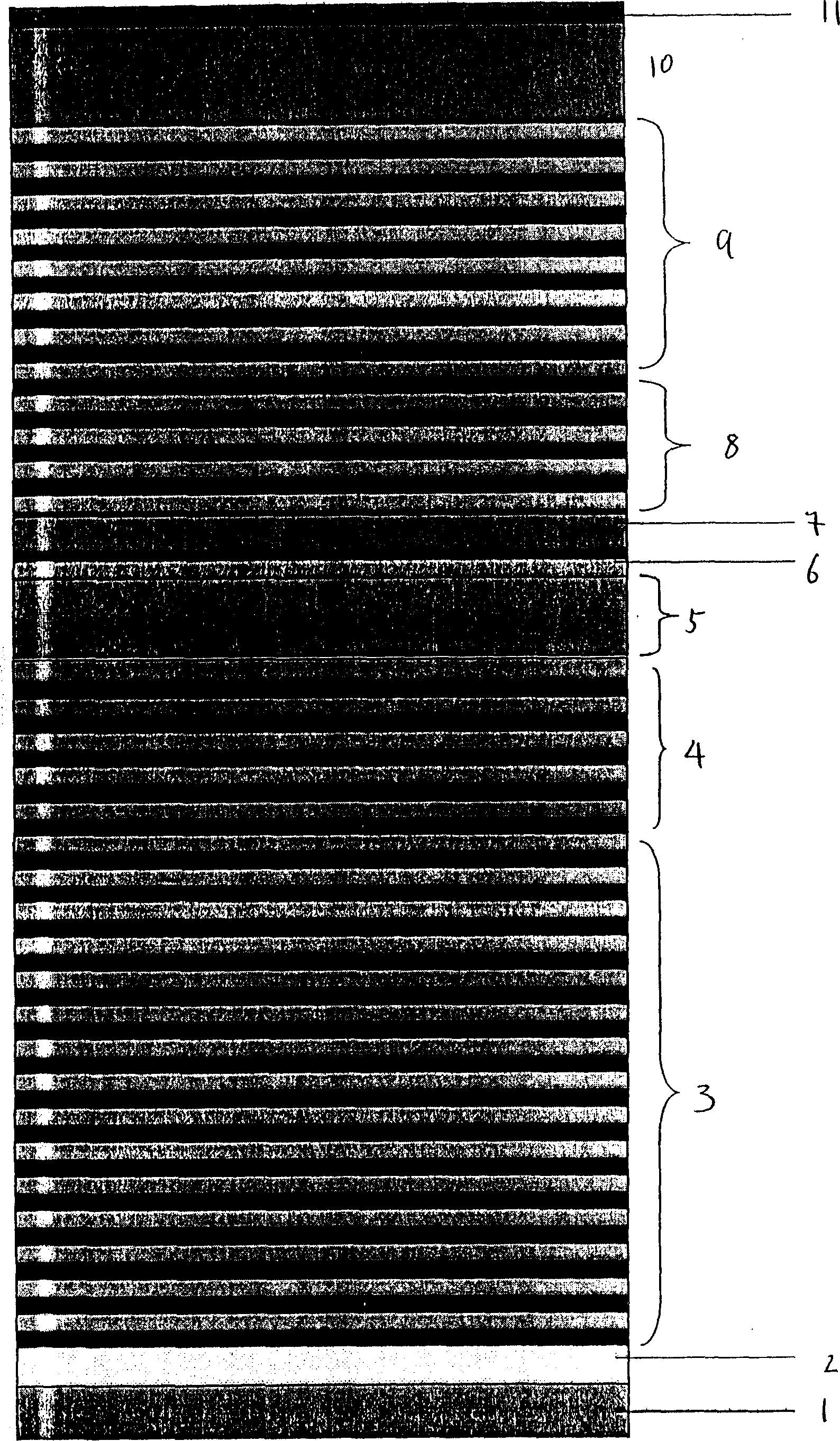

[0028] Referring to the accompanying drawings, the epitaxial structure of the vertical cavity surface emitting semiconductor laser diode includes the following eleven parts, each part is a layer structure, the part (1) is a (100) gallium arsenide substrate, and the crystal orientation deviation angle is 0.8-8 degree, the silicon doping concentration is 0.5-3×10 18 / cc. Part (2) is a grown single-layer gallium arsenide transition layer with a thickness of 3000-7000 Ȧ and a silicon doping concentration of 0.5-3×10 18 / cc. Part (3) is the growth of 30-40 layers of external N-type Bragg reflective layer, the reflective layer is composed of AlGaAs, the thickness conforms to the Bragg reflective definition, and the silicon doping concentration is 0.5-3×10 18 / cc. Part (4) is the growth of 5-10 layers of internal N-type Bragg reflective layer, the reflective layer is composed of AlGaAs, the thickness conforms to the Bragg reflective definition, and the silicon doping concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com