Cutting device and method for T-shaped paper diaper

A belt and diaper technology, applied in the field of T-type diaper production equipment assembly manufacturing, can solve the problems of large suction loss, non-expanding side waist pieces, poor adhesion of side waist pieces, etc., to meet psychological needs and feel good , beautiful shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

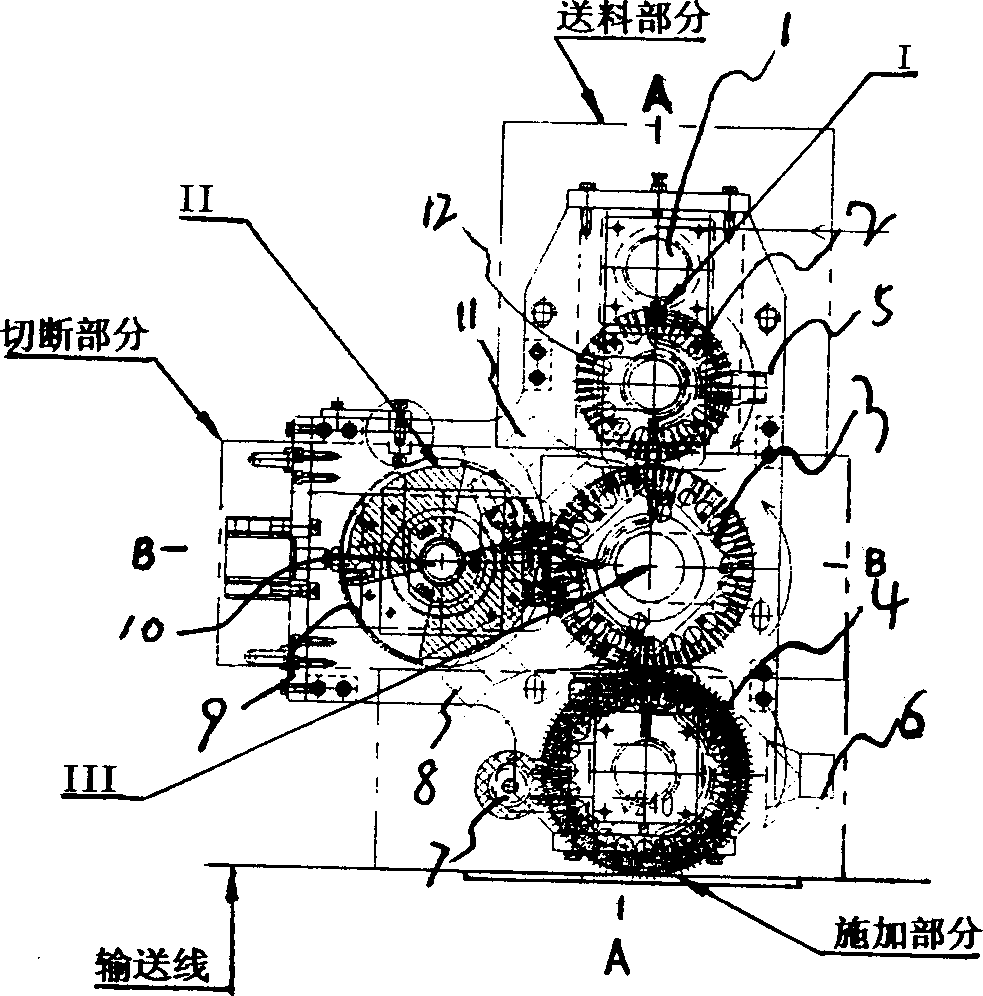

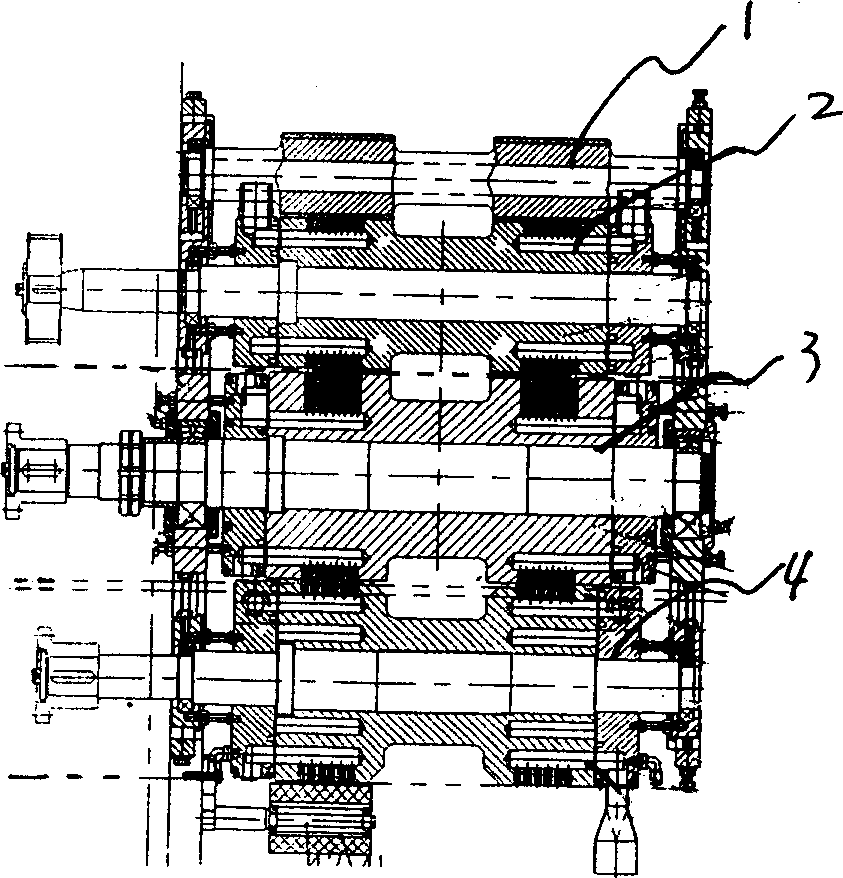

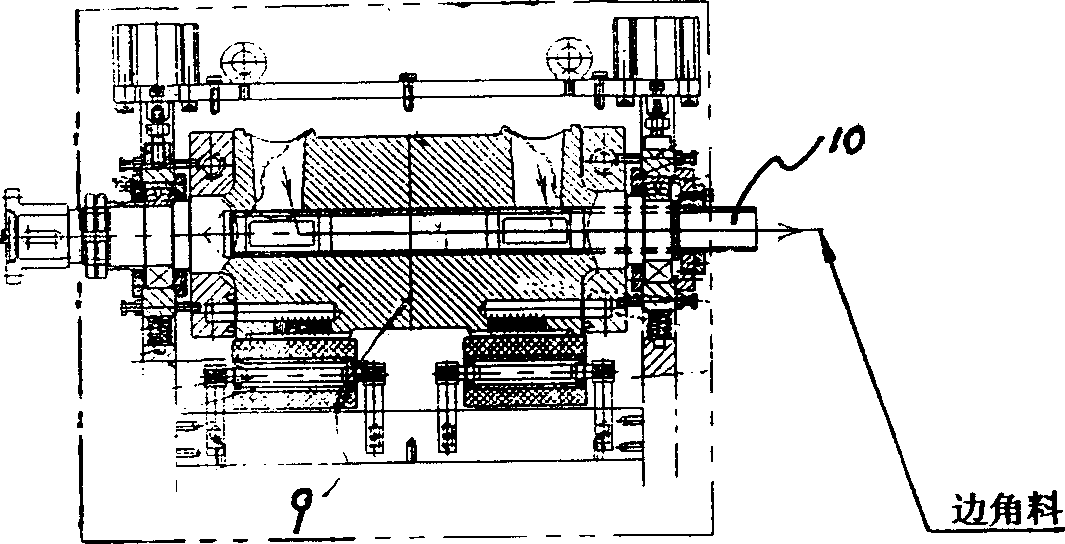

[0013] Embodiment 1: with reference to attached Figure 1~4 . T-shaped diaper side waistband cutting device, feeding pressure roller 1, negative pressure feeding roller 2, negative pressure bottom knife roller 3 and negative pressure application roller 4 are all processed and manufactured by the existing technology and distributed longitudinally (installed by the existing technology) On the frame 5, the leftover material suction cutter wheel 9 adopts prior art processing and is horizontally positioned on the frame and is opposite to the roller surface of the negative pressure bed knife roller 3, and the negative pressure feed roller 2 and the leftover material suction cutter wheel 9 There is an air suction nozzle 11 on the roller surface of the negative pressure bed knife roller 3 that is sandwiched, and the purpose is to suck the leftover material into the cutter wheel 9 and the negative pressure applying roller 2. Air nozzle 8, suction nozzle 6 is arranged on the negative p...

Embodiment 2

[0014] Embodiment 2: with reference to attached Figure 5 . On the basis of embodiment 1, the cutting method of T-shaped diaper side waistband cutting device, when the side sheet passes through the nip roller constituted by the feeding pressure roller and the negative pressure feeding roller, it is adsorbed on the negative pressure feeding roller. The negative pressure bottom knife roller and scraps are sucked into the arc-shaped cutter on the cutter wheel to cut into side belts, and the scraps are sucked into the hollow tube shaft of the cutter wheel by the negative pressure suction channel on the cutter wheel and The external negative pressure is discharged, and the cut side belt is sucked on the negative pressure bed knife wheel. When the side belt on the negative pressure bed knife wheel turns to be tangent to the negative pressure applying roller, the negative pressure bed knife wheel The air distribution of the belt is disconnected, and the cut side waist belt is absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com