Power controller

A technology of power controller and controller, which is applied to control/regulating systems, instruments, regulating electrical variables, etc., can solve the problems of complex manufacturing process and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

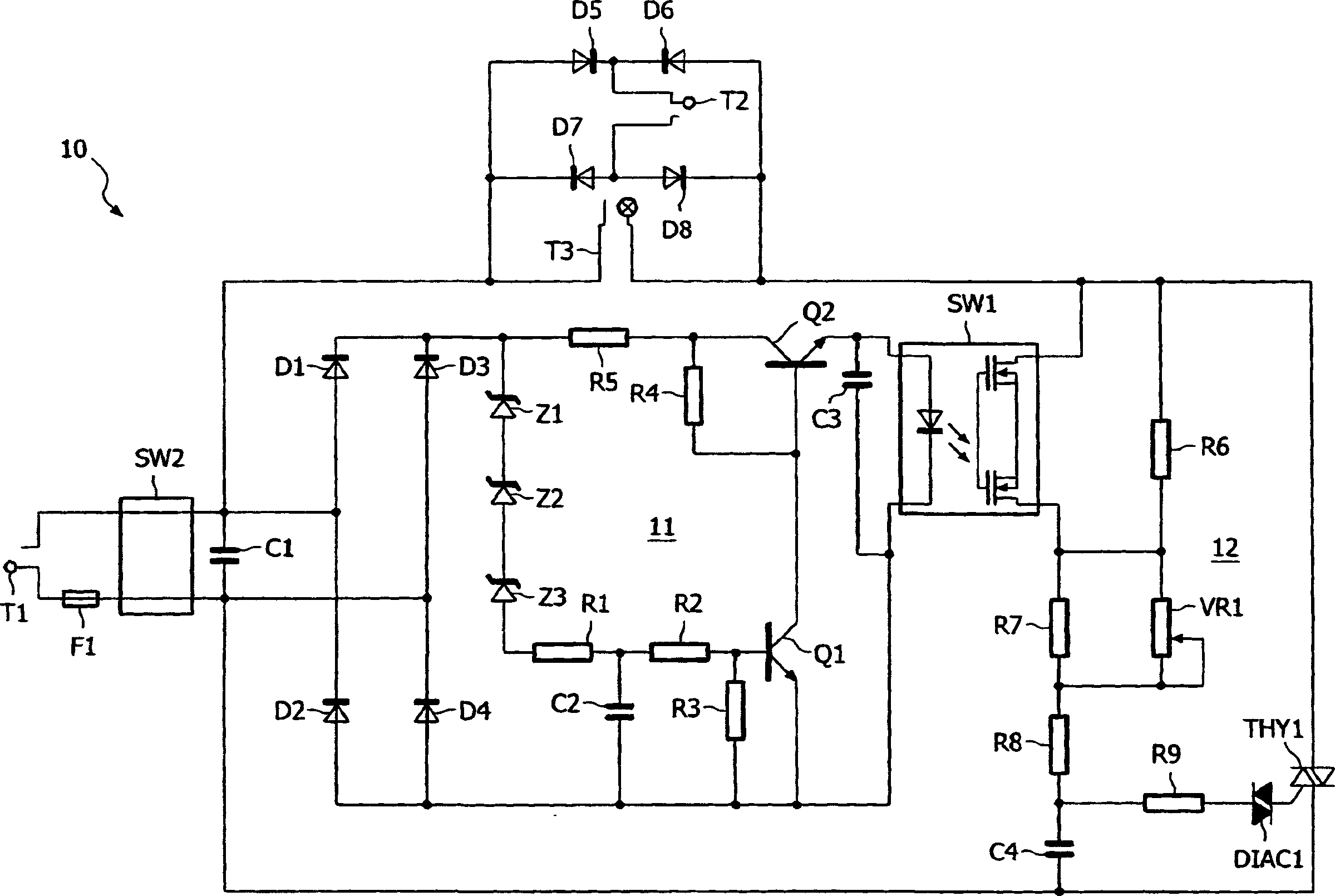

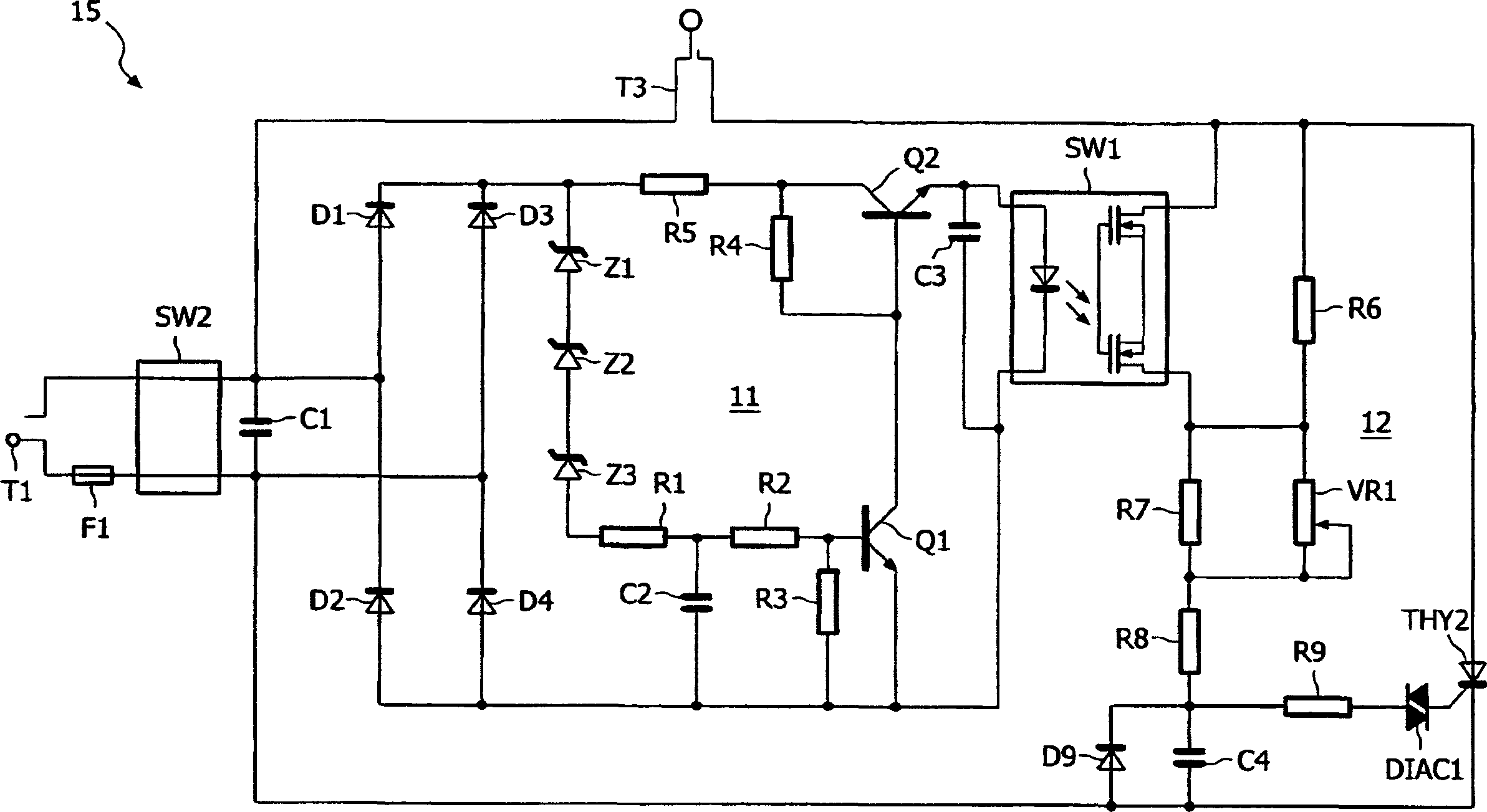

[0017] figure 1 The variable power controller includes an input terminal T1, which is connected to the main circuit through a fuse F1. exist figure 1 , the live terminal of input T1 is shown as the lowest and the highest terminal is the neutral terminal. A power switch SW2 is interposed between the terminals and the power controller circuit, and it is this power switch that is used to operate the circuit.

[0018] Generally, the power controller is configured to provide 110V, 50Hz or 60Hz power to the load connected to the output terminal T3. The power received by the input terminal T1 can be 110V or 240V, 50Hz or 60Hz.

[0019] The power controller 10 can be considered to be reconstituted by two main parts, a controller 11 and a trigger circuit 12, each of which is connected to receive power supplied to the input terminal T1. The first capacitor C1 is connected between output terminals of the power switch SW2. The first capacitor C1 is an X2-level capacitor, which can pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com