Box girder-moving trolley

A trolley and box girder technology, applied in bridges, bridge parts, bridge construction, etc., to achieve the effect of low investment cost, stable operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments are further described below in conjunction with the accompanying drawings.

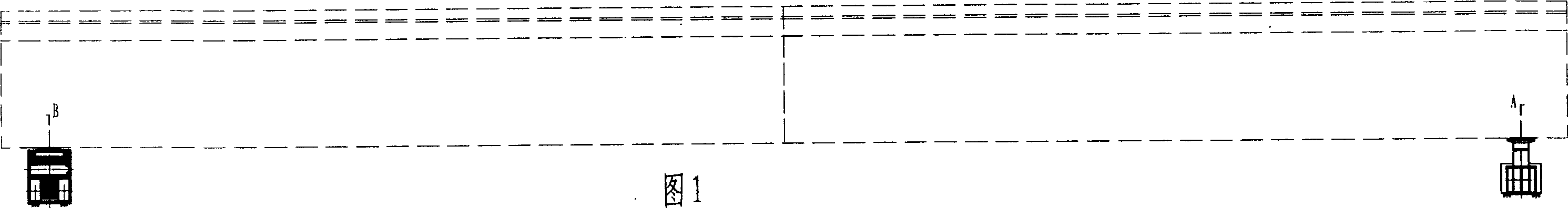

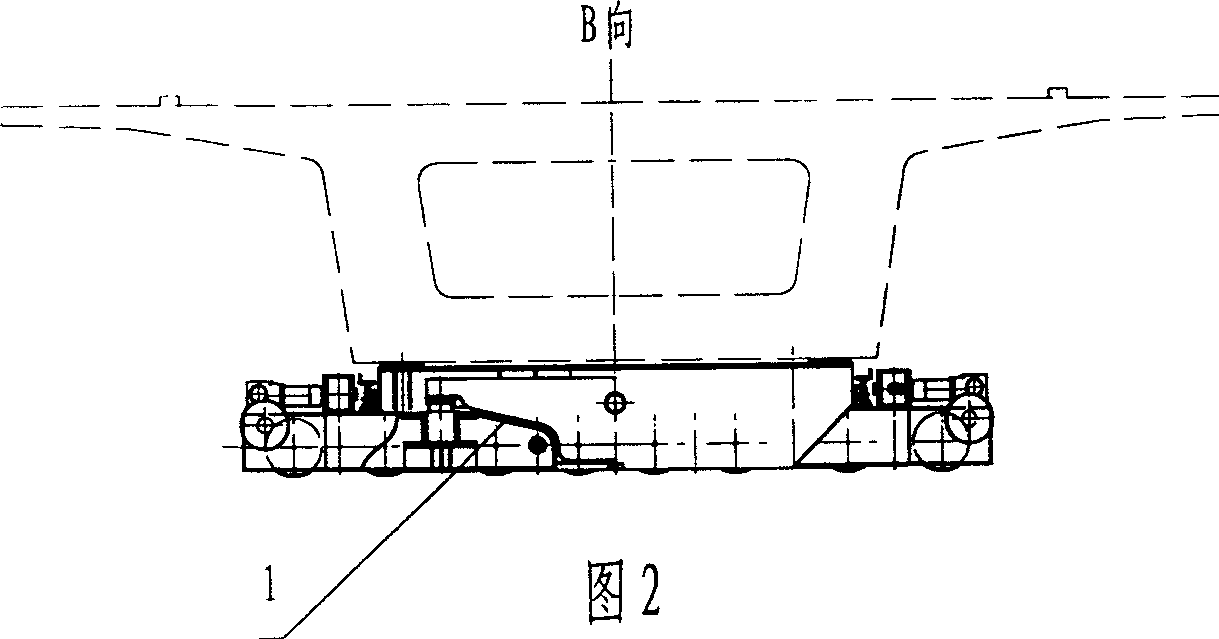

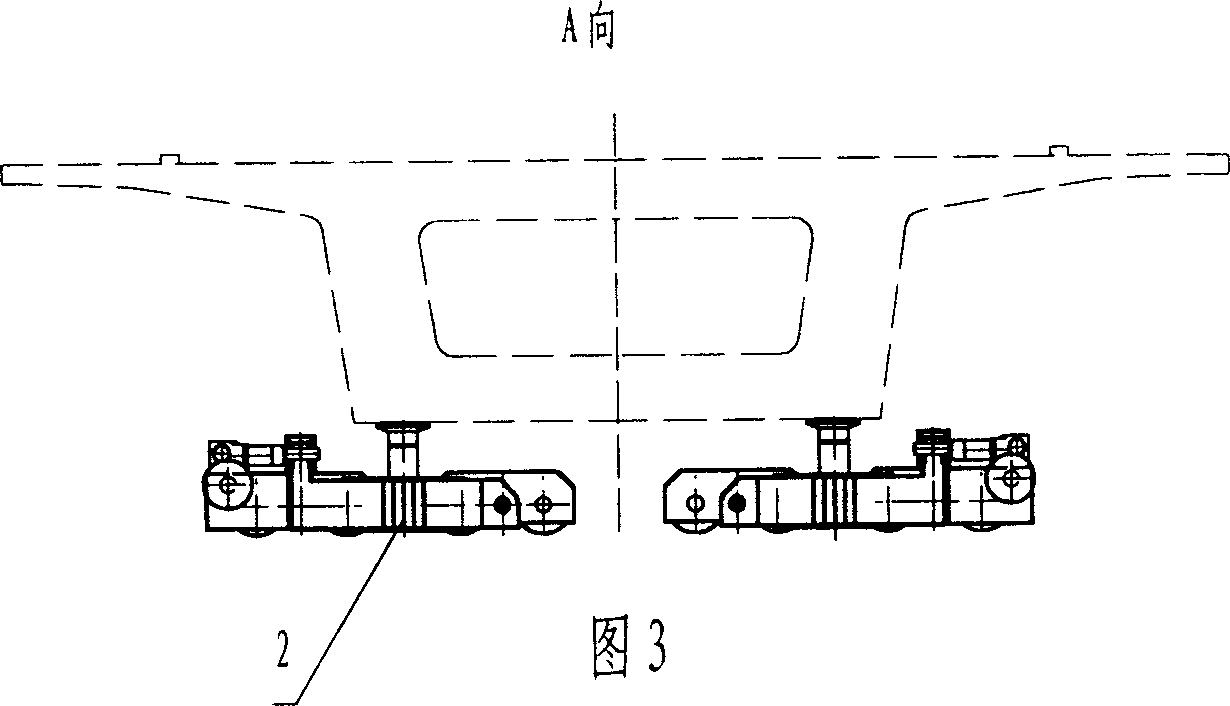

[0025] Referring to Fig. 1, Fig. 2, Fig. 3, 1-flexible support trolley, 2-rigid support trolley. As shown in the figure, there is one flexible support trolley and two rigid support trolleys, which are installed side by side and placed on four rails on both sides of the beam making yard. The dotted line frame in the figure shows the overall shape of the box girder. The main structure of the invention includes two rigidly supported trolleys, one softly supported trolley, a speed measuring device, a force measuring device, an alarm device, a hydraulic control part and an electrical control part. The flexible support trolley is composed of 4 active bicycles and 4 passive bicycles, which are hinged together with small balance beams, solid beams and outer frame beams. The rigid support trolley is composed of 2 active bicycles and 2 passive bicycles hinged together by a balance beam. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com