Oil leakage-proof and dust-proof device of sewing machine

A technology for dust-proof device and sewing machine, which is applied to sewing machine components, sewing equipment, safety devices, etc., can solve the problems of easy retention of lubricating oil, damage to the dust-proof function, and deterioration of the effect of scraping oil, so as to improve the scraping ability, The effect of strong sealing performance and stable dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

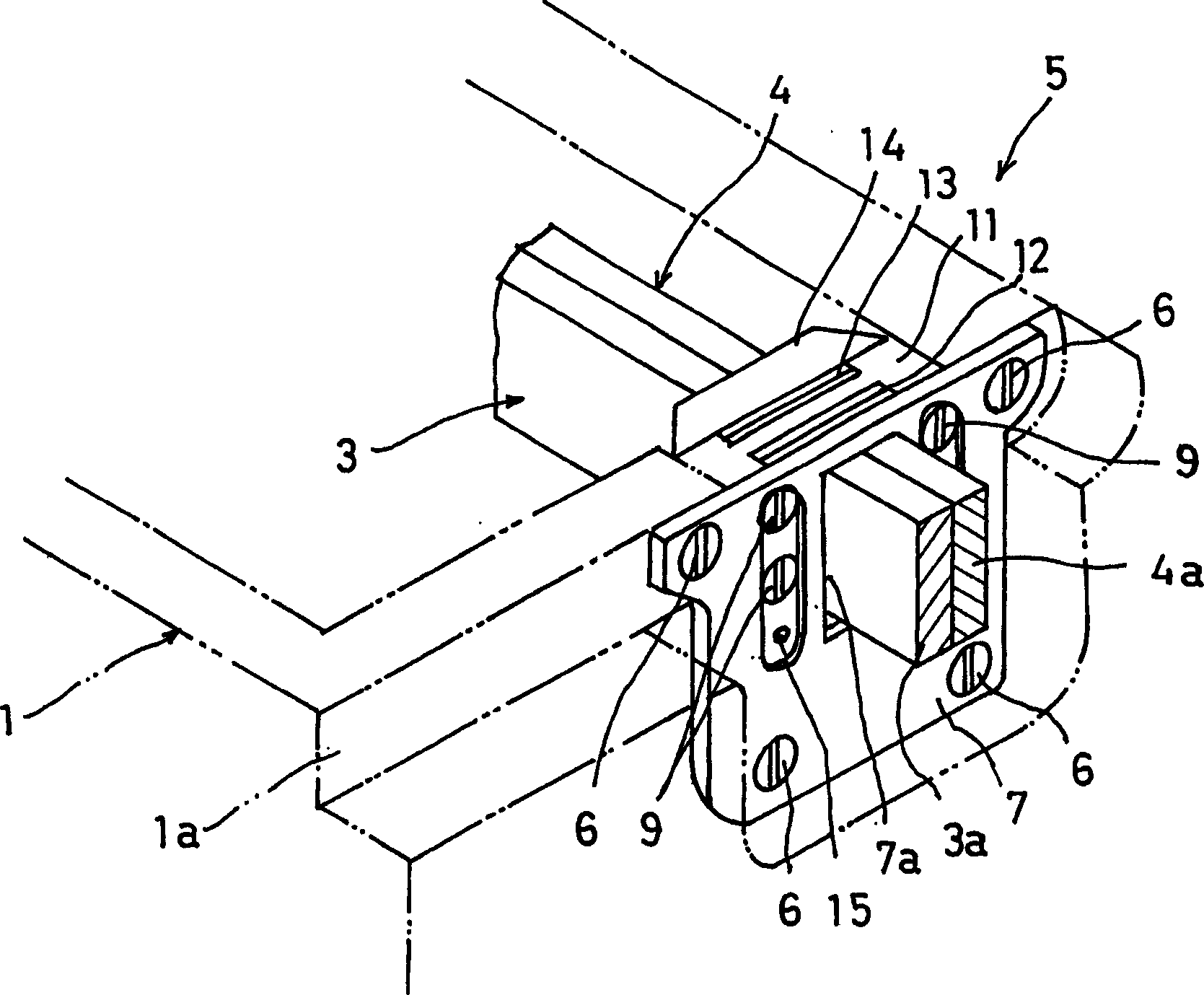

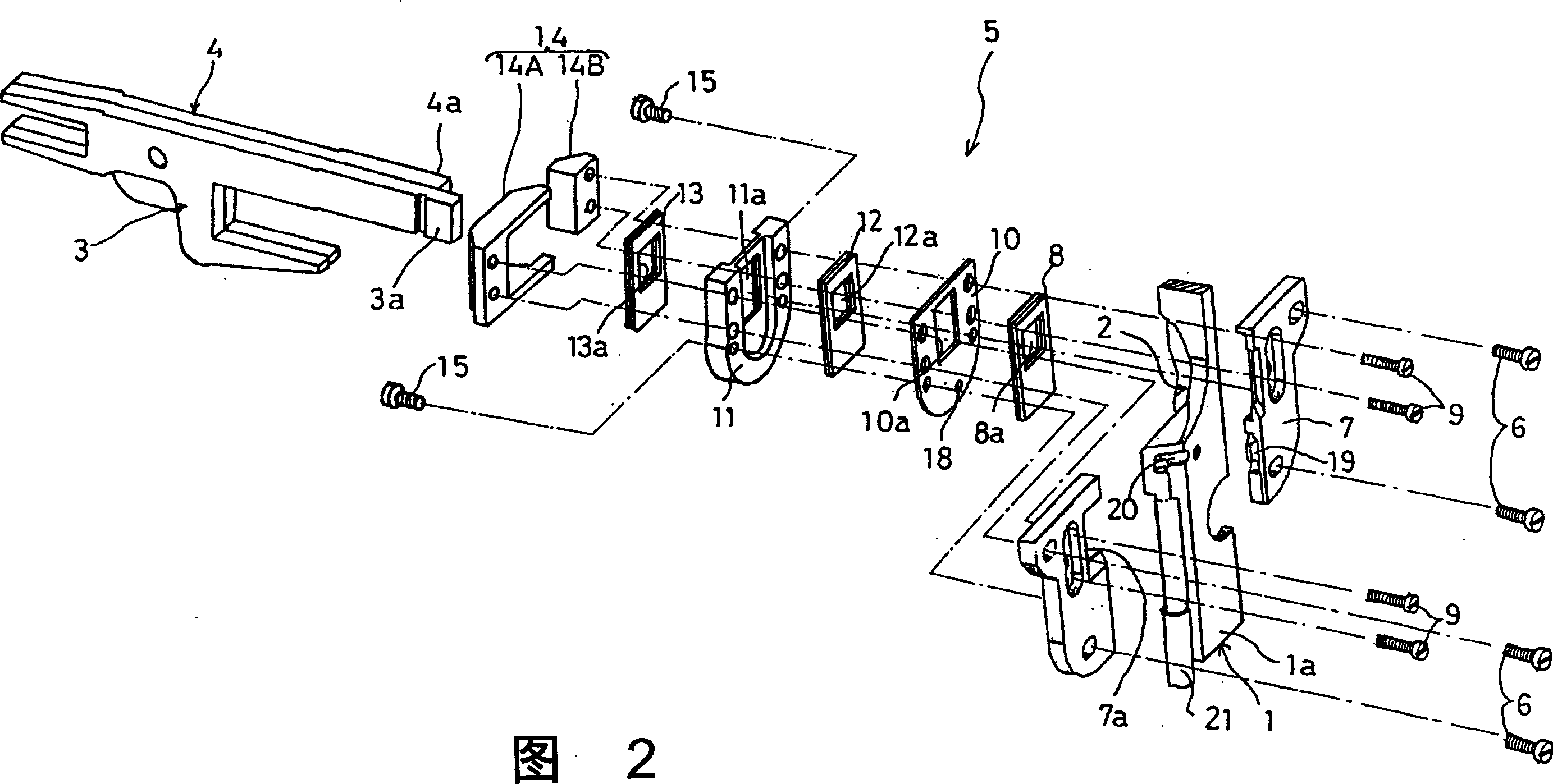

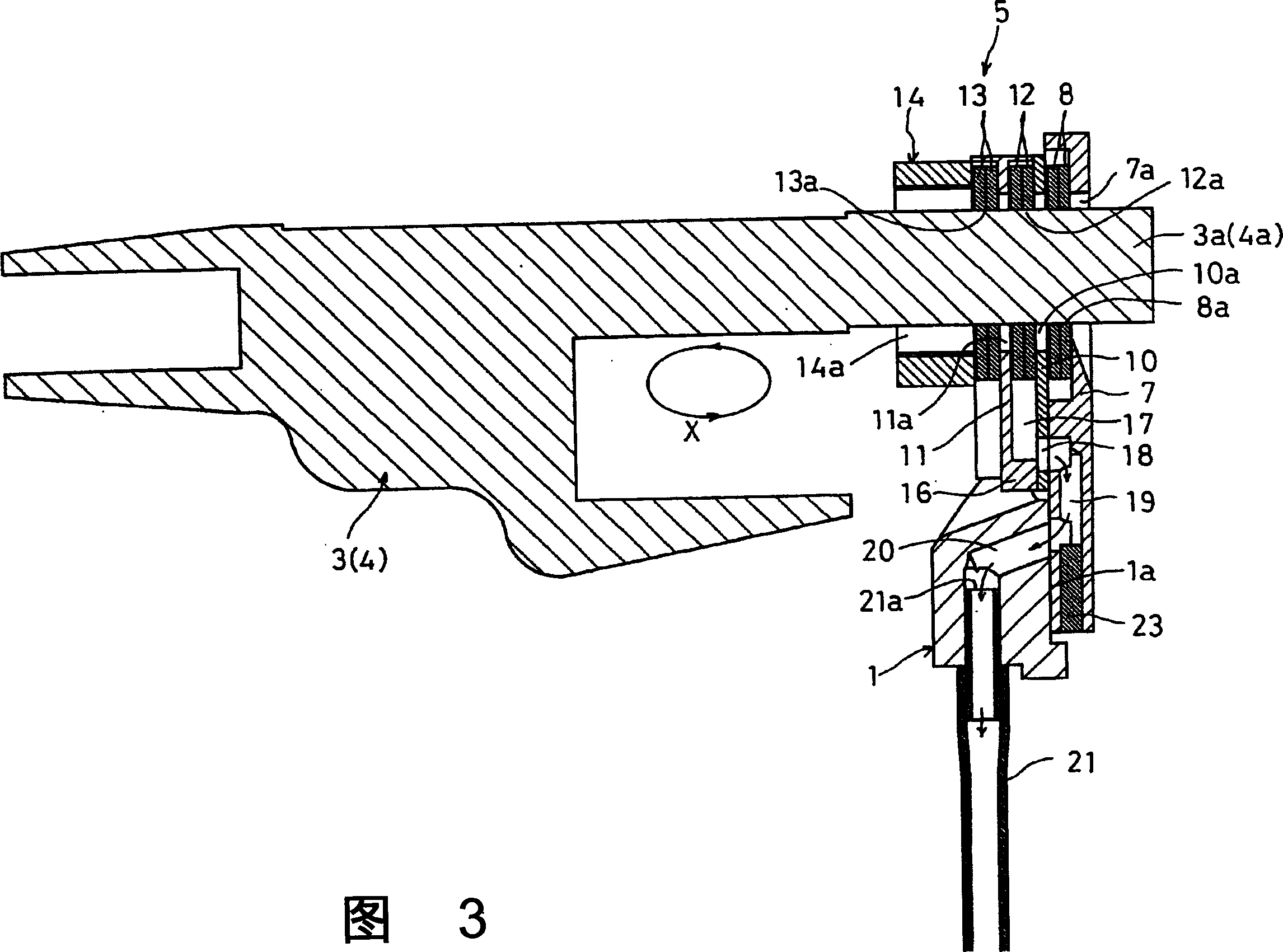

[0020] figure 1It is a schematic perspective view of important parts, which shows the state where the oil leakage prevention and dust prevention device of the present invention is assembled on the table part of the overlock sewing machine. Fig. 2 is an exploded isometric view of important parts. Fig. 3 is an enlarged longitudinal sectional side view of an assembled state.

[0021] In each of the above-mentioned figures, 1 is a sewing machine frame constituting a table portion, and an opening 2 is formed in a front surface portion 1 a of the sewing machine frame 1 . Inside the above-mentioned sewing machine frame 1, a pair of front and rear swing cloth feed tables 3, 4 for the cloth feed device are supported so that they can swing back and forth and up and down, and the front and rear pair of swing cloth feed tables 3, 4 Top end portions 3a, 4a protrude to the outside of the sewing machine frame 1 through the opening 2, and front and rear feed dogs (not shown) are mounted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com