Vacuum heat-preserving tube

A technology of vacuum insulation and vacuum chamber, applied in the direction of heat preservation, pipeline protection through heat insulation, pipeline protection, etc., can solve the problems of vacuum insulation pipe damage, linear expansion difference, high operating cost, etc., achieve low cost, reduce consumption, and facilitate transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

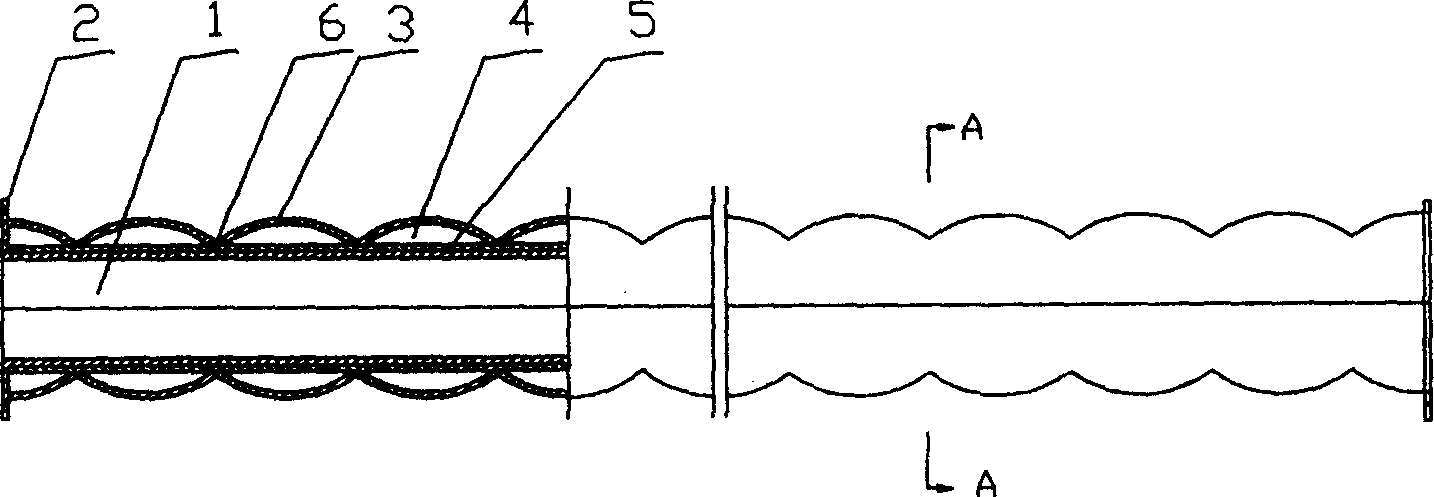

[0022] Embodiment 1: as figure 1 with image 3 As shown, the vacuum insulation pipe includes a pipe body 1 with flanges 2 at both ends of the pipe body 1; it is characterized in that: the outside of the pipe body 1 is covered with a sleeve 3 with a continuous corrugated structure, which is connected with the pipe body 1 and the flange. 2 together form a vacuum chamber 4; the outer wall of the tube body 1 is provided with a number of continuous or discontinuous support ribs or support points 5 along the axial direction of the tube body 1, and each inner edge 6 of the corrugated structure of the casing 3 is supported on the support ribs or support points 5 , the purpose of which is to make the vacuum chambers between the corrugations communicate.

Embodiment 2

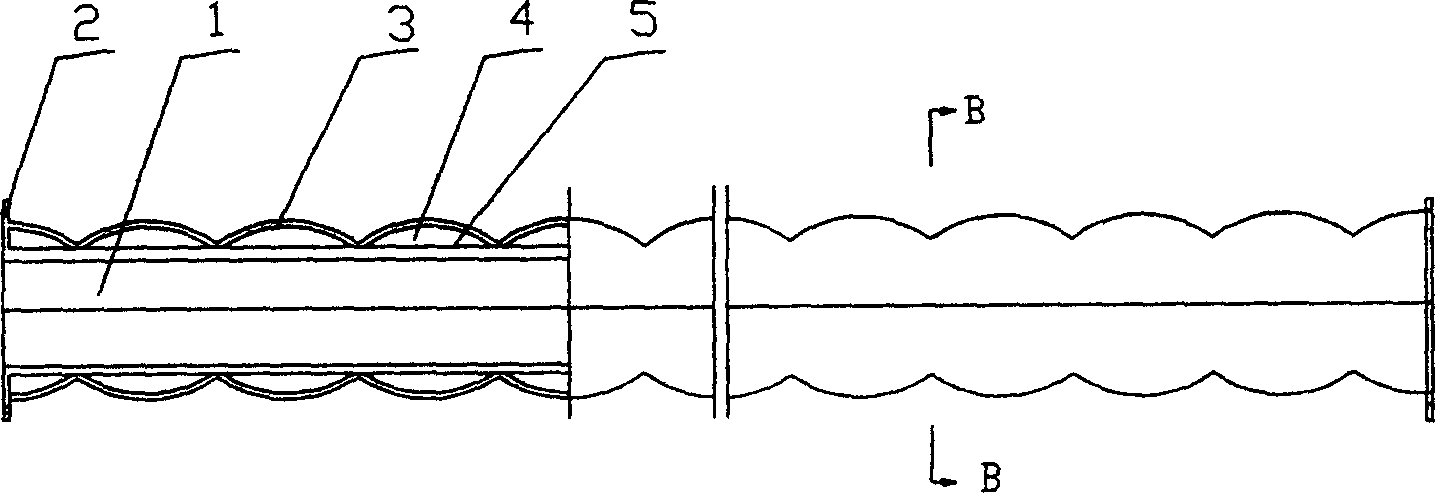

[0023] Embodiment 2: as figure 2 with Figure 4 As shown, the vacuum insulation pipe includes a pipe body 1 with flanges 2 at both ends of the pipe body 1; it is characterized in that: the outside of the pipe body 1 is covered with a sleeve 3 with a continuous corrugated structure, which is connected with the pipe body 1 and the flange. 2 together form a vacuum chamber 4; each inner edge 6 of the corrugated structure of the sleeve 3 has a number of small gaps 7 (the purpose is to make the vacuum chambers between the corrugations communicate), and each inner edge 6 of the corrugated structure of the sleeve 3 supports on body 1.

Embodiment 3

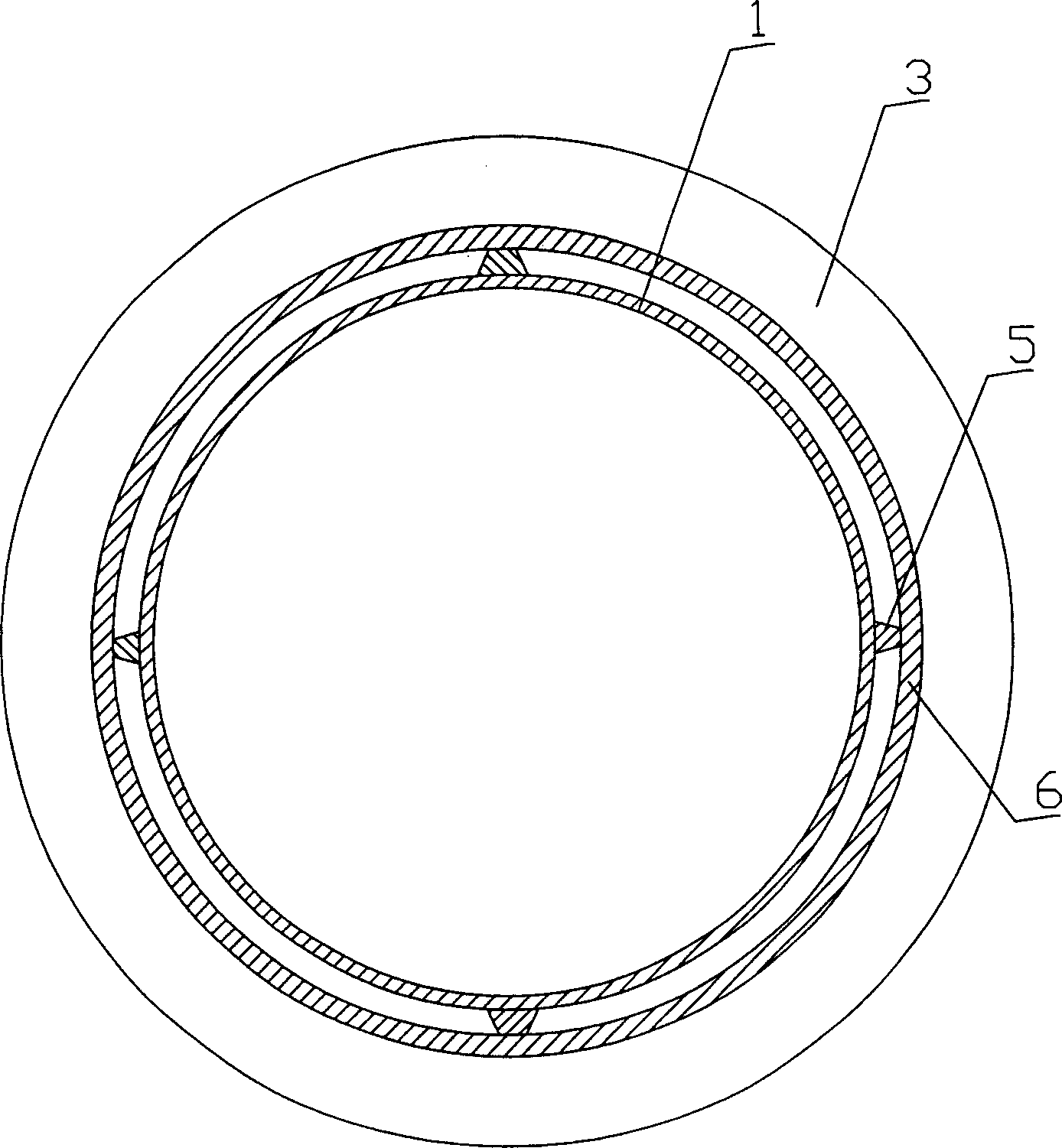

[0024] Embodiment 3: as figure 2 with Figure 5 As shown, the vacuum insulation pipe includes a pipe body 1 with flanges 2 at both ends of the pipe body 1; it is characterized in that: the outside of the pipe body 1 is covered with a sleeve 3 with a continuous corrugated structure, and the sleeve is arranged along its radial direction. It is continuously corrugated, and at the same time, the circumference along its cross section is also

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com