Method for culturing heterotrophic chlorella with high density

A heterotrophic chlorella, high-density culture technology, applied in the field of high-density culture of heterotrophic chlorella, can solve the problem of low glucose utilization rate of heterotrophic chlorella, to alleviate damage, improve efficiency, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

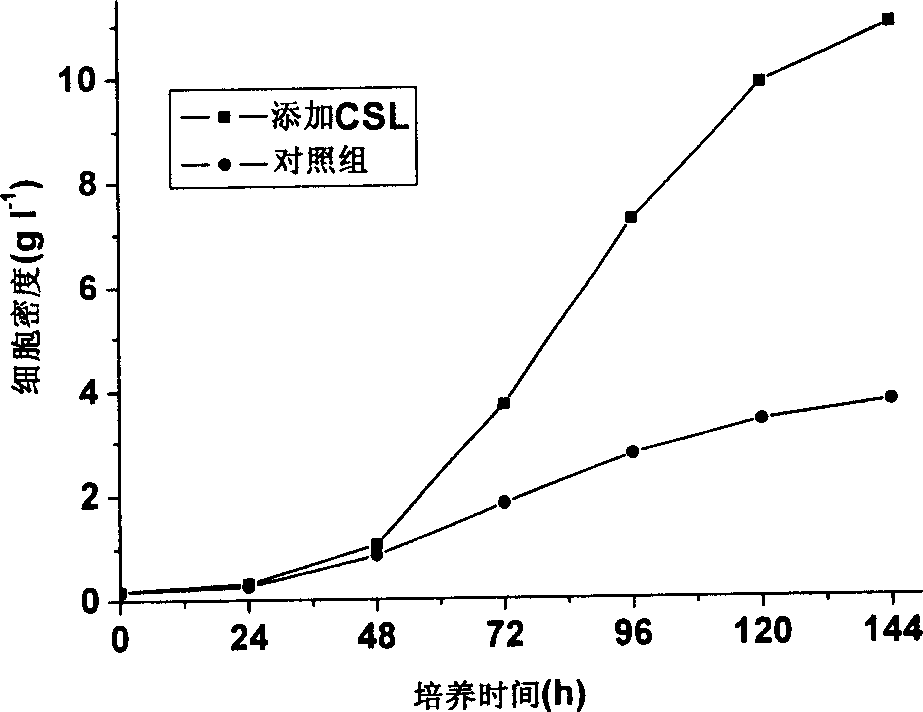

[0023] Under the condition of medium glucose concentration of 10g / l, the effect of adding CSL or not on the growth state of heterotrophic algae cells is shown as follows figure 1 shown.

[0024] A glucose concentration of 10 g / l is widely reported as an optimal condition for the growth of heterotrophic Chlorella. After 144 hours of cultivation, without adding CSL, the algal cell density was 3.74g / l; after adding 1‰ of CSL, the cell density was as high as 10.95g / l, which was 293% of the control group. The residual sugar in the culture solution without CSL was as high as 6.49g / l, and the residual sugar in the culture solution added with CSL was only 0.12g / l, and the utilization rate of glucose increased from 35.1% to 98.8%. It indicated that the addition of CSL greatly promoted the growth of heterotrophic Chlorella and fully utilized glucose.

Embodiment 2

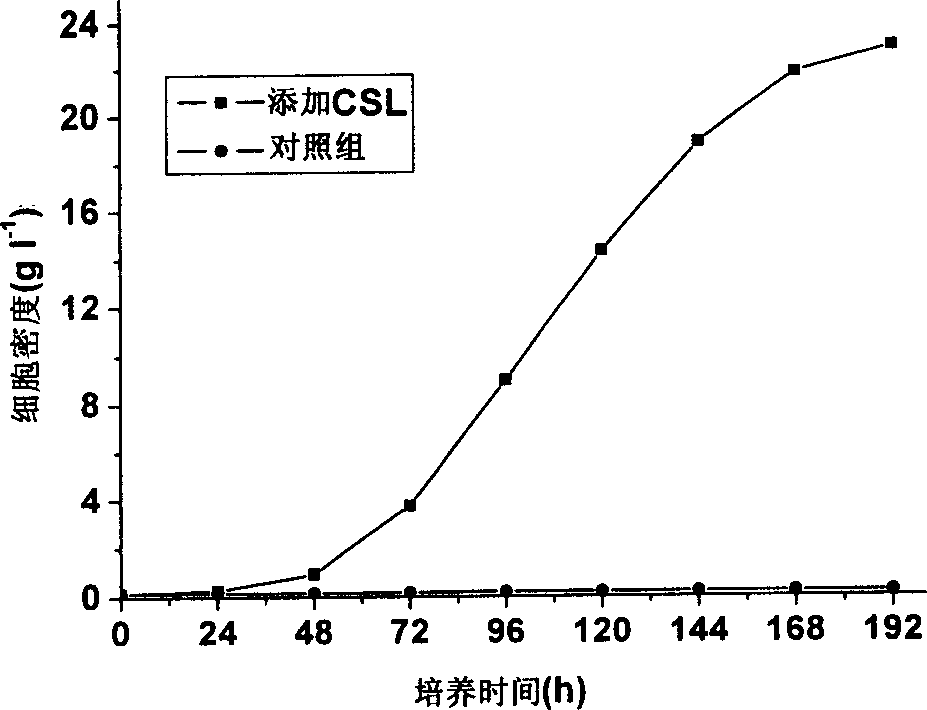

[0026] Under the condition of medium glucose concentration of 30g / l, whether to add CSL or not to the influence of the growth state of heterotrophic algae cells, the results show as follows figure 2 shown.

[0027] After 144 hours of cultivation, without adding CSL, the algal cell density was 0.22g / l, compared with the algal cell concentration of 0.17g / l after inoculation, it can be considered that the high concentration of glucose of 30g / l basically inhibited the growth of algae. After adding 1.5‰ of CSL, the cell density reached 18.01g / l, the residual sugar was 0.13g / l, and the utilization rate of glucose was 99.6%. It indicated that the addition of CSL alleviated the damage of high concentration glucose to Chlorella and stimulated the growth of Chlorella.

Embodiment 3

[0029] Under the condition of medium glucose concentration of 50g / l, the effect of adding CSL or not on the growth state of heterotrophic algae cells is shown as follows image 3 shown.

[0030] After 192 hours of cultivation, the growth of algae was inhibited without adding CSL. After adding 2‰ of CSL, the cell density reached 22.97g / l, the residual sugar was 8.40g / l, and the utilization rate of glucose was 83.2%. It shows that with the increase of glucose concentration, the density of harvested cells increases, but the utilization rate of algal cells to glucose decreases, the growth cycle is prolonged, and the efficiency of converting sugar into biomass decreases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com