Chip welding device and method using same

A chip welding and chip technology, which is applied in welding equipment, water conservancy projects, marine engineering and other directions, can solve the problem of high cost of device manufacturing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

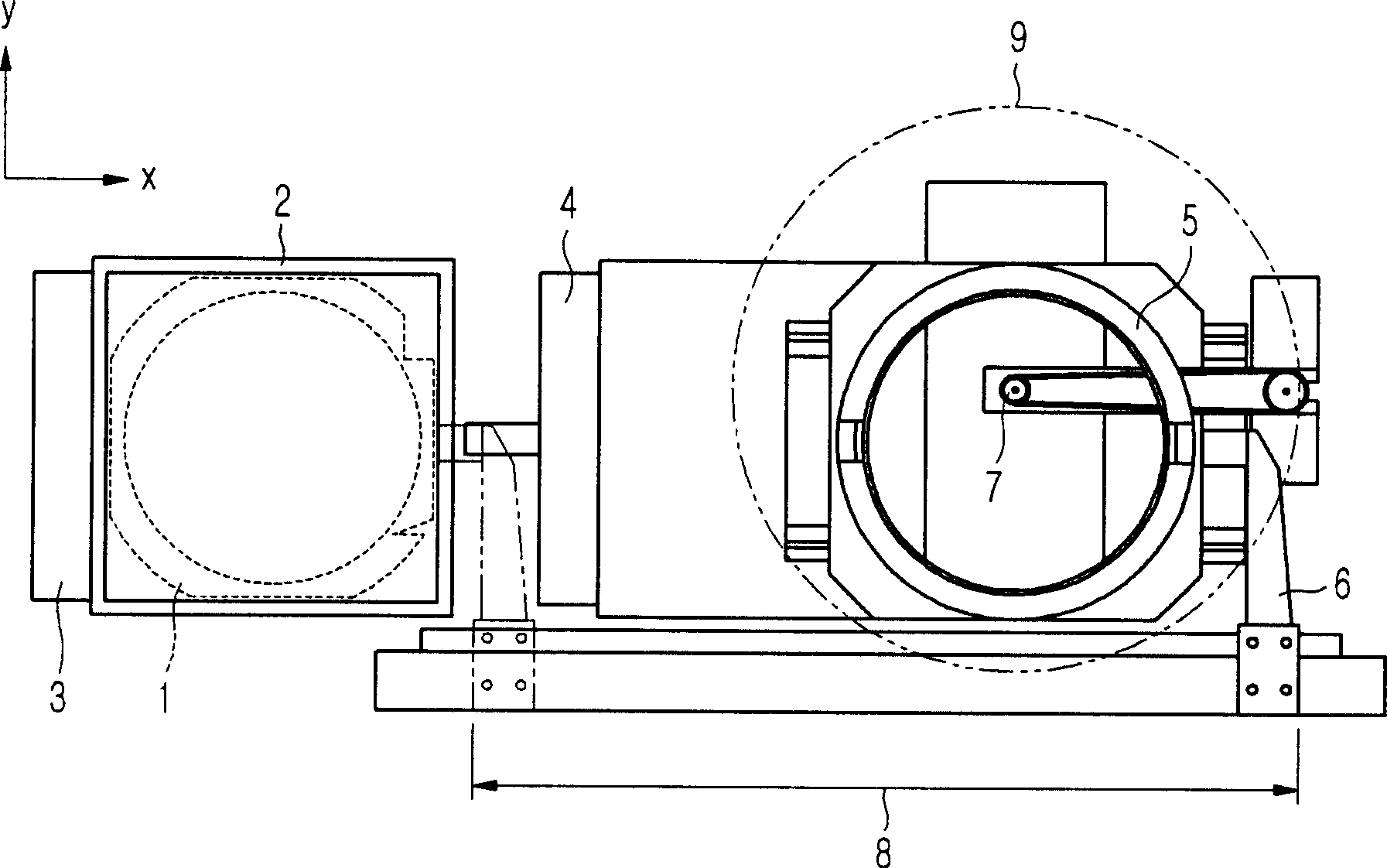

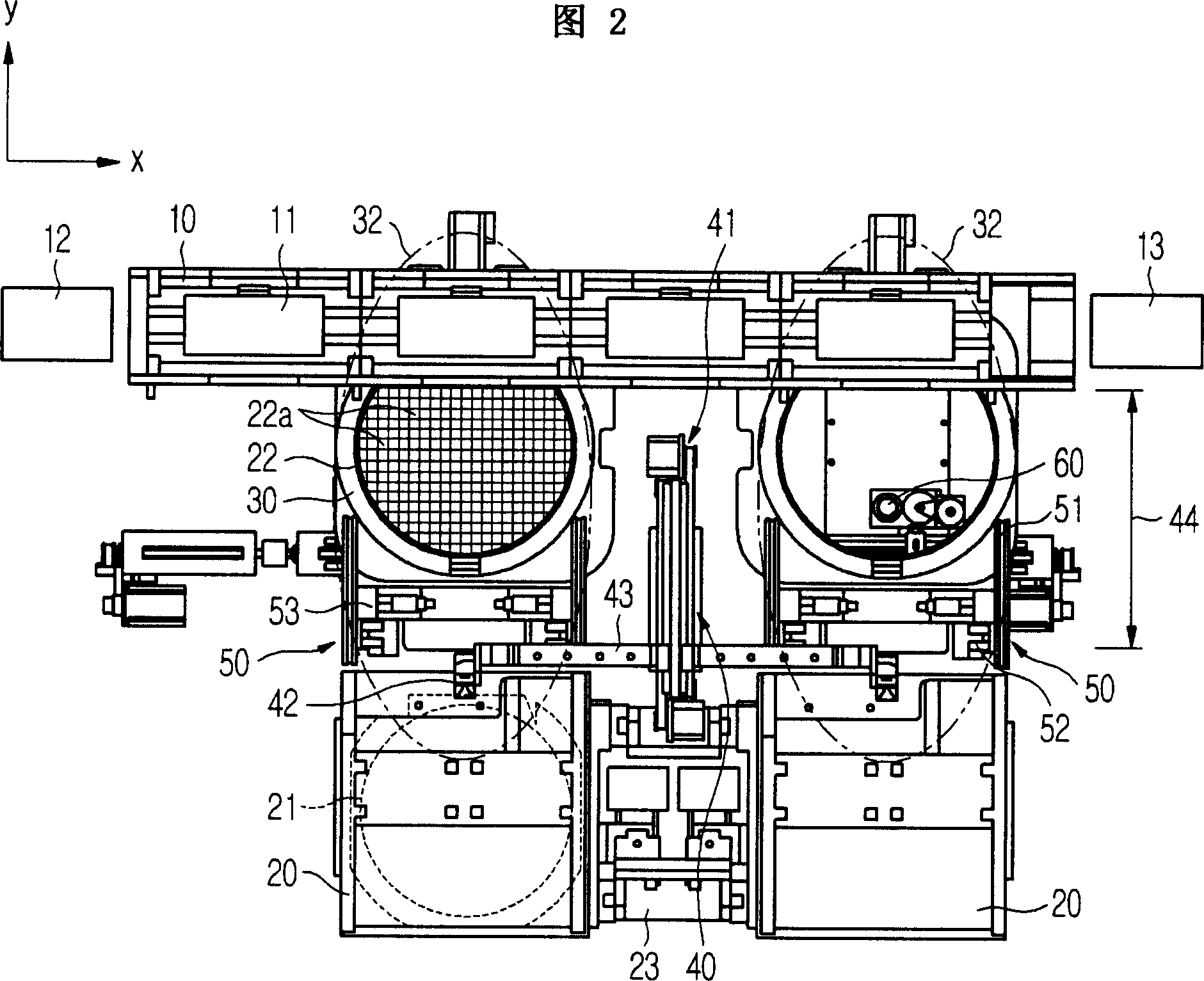

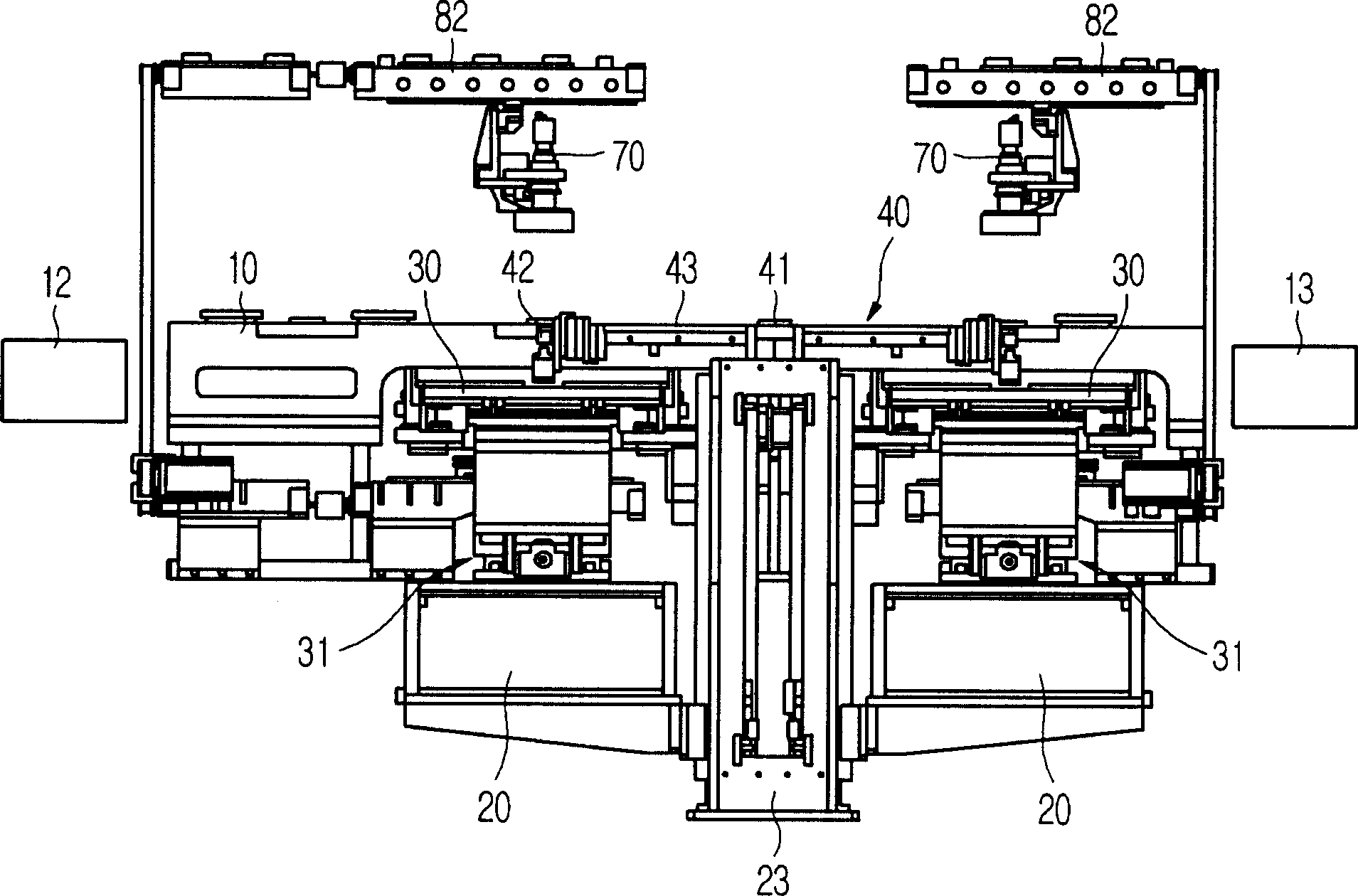

[0027] Hereinafter, embodiments according to the present invention will be described in detail with reference to the accompanying drawings. Fig. 2 is a schematic plan view showing a chip bonding device provided according to the present invention, image 3 It is a schematic front view showing a chip bonding device provided according to the present invention.

[0028] Figure 2 and image 3 As shown, the die bonding apparatus provided according to the present invention includes a lead frame moving part related to lead frame movement, a wafer moving part related to wafer loading and unloading and wafer movement for determining the position of a chip to be picked up, and a wafer moving part related to wafer movement. The chip moving part related to Die Attach that picks up the chip and attaches it to the lead frame.

[0029] The lead frame moving part is located on the rear side of the device, and includes an indicator track 10 for carrying and transferring the lead frame 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com