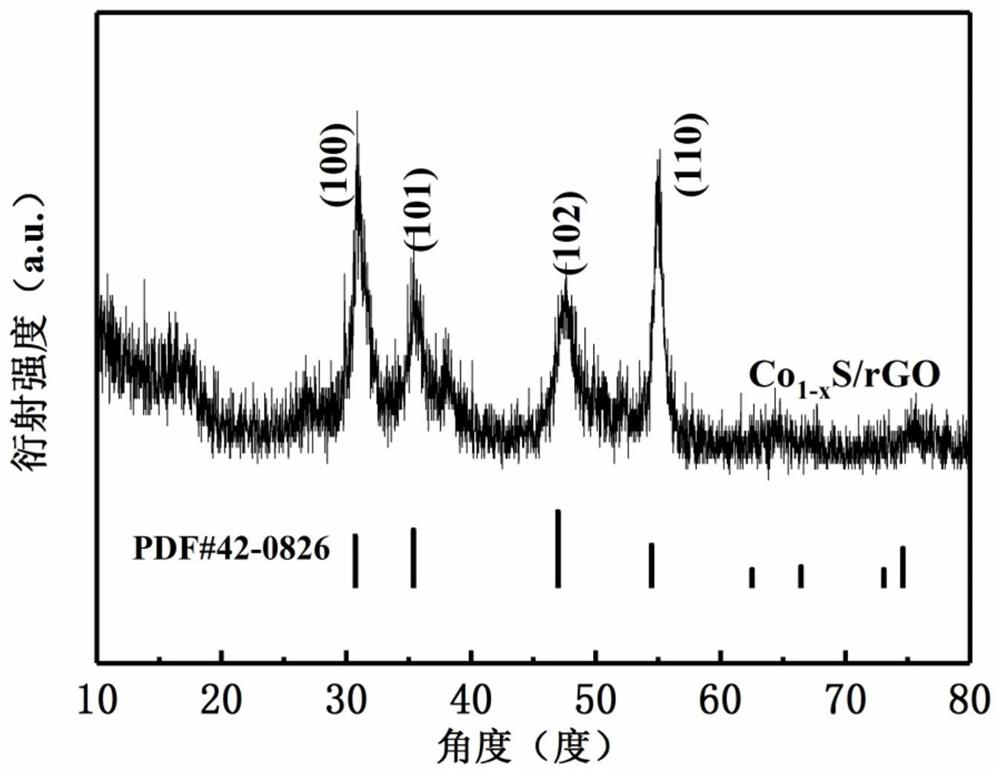

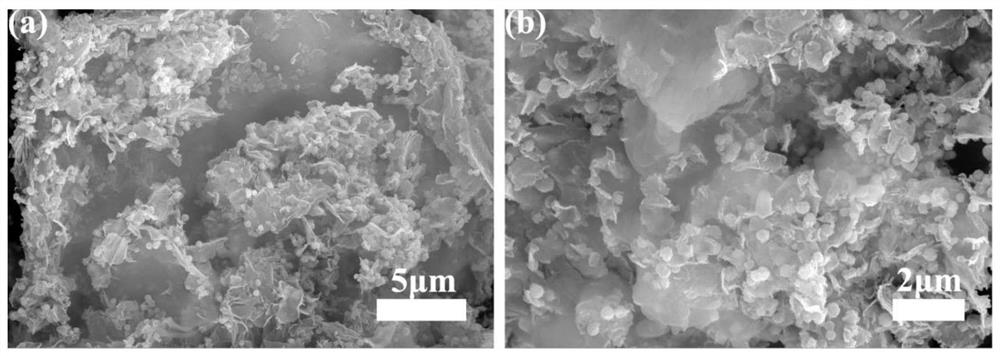

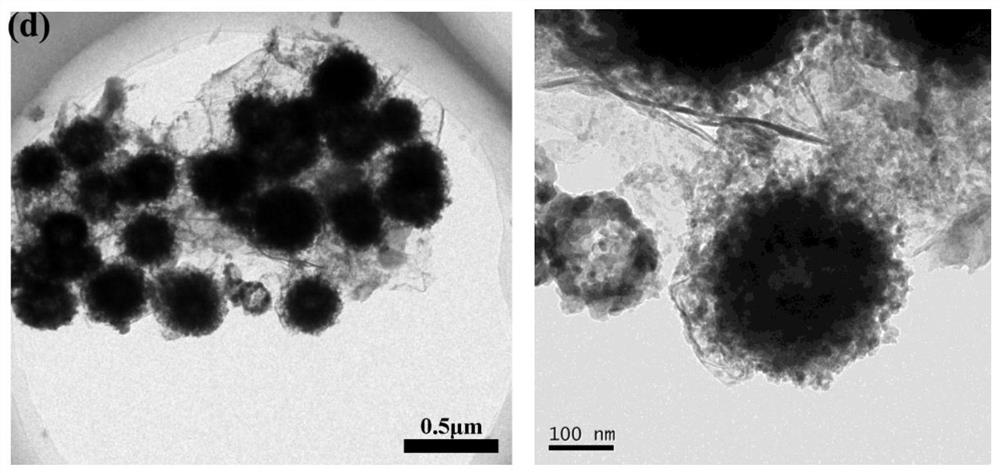

Preparation method and application of a hollow spherical cobalt sulfide/graphene composite material

A composite material and graphene technology, applied in the field of composite materials, can solve the problems of cobalt sulfide easy to agglomerate theoretical specific capacity, serious volume expansion effect, unsuitable for lithium-ion batteries, etc., to reduce material and charge transfer paths, low cost, The effect of increasing and electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Add 0.375mmol (0.1091g) cobalt nitrate hexahydrate and 8mL glycerin to 40mL isopropanol, stir, hydrothermally react at 180°C for 6 hours, centrifuge at 6000rpm / min, and deionize the precipitate with deionized water and absolute ethanol Cross-washed 6 times respectively, and dried at 70°C to obtain the cobalt-glycerol complex;

[0046] (2) Add 2.5mL of 3-aminopropyltrimethoxysilane to 30mL of absolute ethanol solution containing 50mg of cobalt-glycerol complex, stir at 300r / min for 12h, ultrasonicate at 400W for 4h, and centrifuge at 6000rpm / min. Deionized water and absolute ethanol were cross-washed 5 times respectively to obtain 30 mL ethanol solution containing cobalt-glycerol complex;

[0047] (3) Add 15mg of graphene oxide into 20mL of absolute ethanol solution, and disperse with 400W ultrasonic for 2 hours to obtain a uniform and stable graphene oxide dispersion. / min stirring for 5h, 400W ultrasonic treatment for 4h, to obtain a uniform and stable mixed solut...

Embodiment 2

[0056] (1) Add 0.375mmol (0.1091g) cobalt nitrate hexahydrate and 16mL glycerin to 40mL isopropanol, stir, carry out hydrothermal reaction at 180°C for 4 hours, centrifuge at 6000rpm / min, and deionize the precipitate with deionized water and absolute ethanol Cross-washed 6 times respectively, and dried at 70°C to obtain the cobalt-glycerol complex;

[0057] (2) Add 2.5mL of 3-aminopropyltrimethoxysilane to 30mL of absolute ethanol solution containing 30mg of cobalt-glycerol complex, stir at 300r / min for 12h, ultrasonicate at 400W for 4h, and centrifuge at 6000rpm / min. Deionized water and absolute ethanol were cross-washed 5 times respectively to obtain 30 mL ethanol solution containing cobalt-glycerol complex;

[0058] (3) Add 10 mg of graphene oxide into 20 mL of absolute ethanol solution, and disperse with 400W ultrasonic for 2 hours to obtain a uniform and stable graphene oxide dispersion; Min stirring for 5 hours, 400W ultrasonic treatment for 4 hours, to obtain a uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com