A kind of bimetallic sulfide composite electrocatalyst and its preparation method and application

An electrocatalyst and sulfide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effect of high hydrophilicity, large specific surface area, and shortened path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

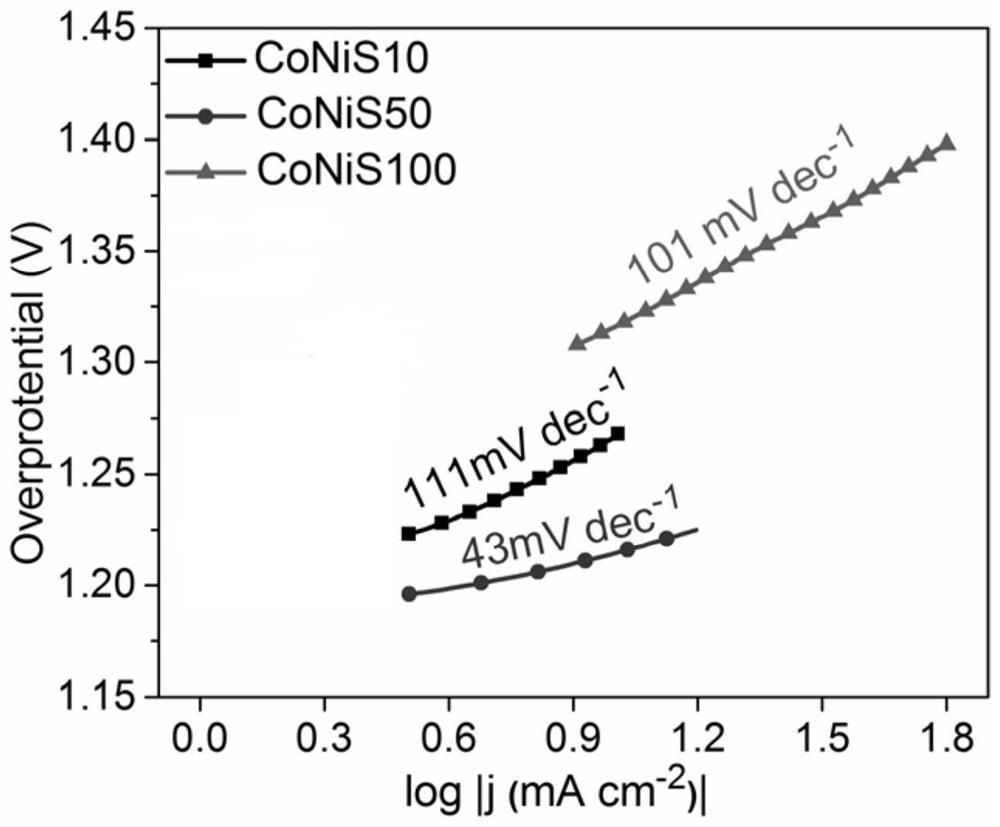

Embodiment 1

[0032]A method for preparing a bimetallic sulfide composite electrocatalyst includes the following steps:

[0033](1) First, set the area to 0.25cm2The nickel foam (NF) is soaked in acetone for 1h to remove impurities, and then treated with a 3mol / L hydrochloric acid aqueous solution for 2h to remove the surface nickel oxide layer. After the treatment, the foam nickel (NF) is washed with deionized water and ethanol, and finally placed It is dried in a vacuum drying oven at a temperature of 313k for 6-12 hours to obtain a pretreated foamed nickel sample.

[0034](2) Using hydrothermal method to combine 10mg thiourea and 383mg Co(NO3)2·6H2O was dissolved in 36mL of deionized water, stirred into a transparent solution and placed in a 50mL hydrothermal kettle together with foamed nickel (NF), reacted at a temperature of 453K for 12h, after the hydrothermal reaction was completed, it was naturally cooled to room temperature, the reactants Rinse it several times with deionized water and absolut...

Embodiment 2

[0036]A preparation method of a bimetallic sulfide composite electrocatalyst includes the following steps:

[0037](1) First set the area to 0.25cm2The nickel foam (NF) is soaked in acetone for 1h to remove impurities, and then treated with a 3mol / L hydrochloric acid aqueous solution for 2h to remove the surface nickel oxide layer. After the treatment, the foam nickel (NF) is washed with deionized water and ethanol, and finally placed It is dried in a vacuum drying oven at a temperature of 313k for 6-12 hours to obtain a pretreated foamed nickel sample.

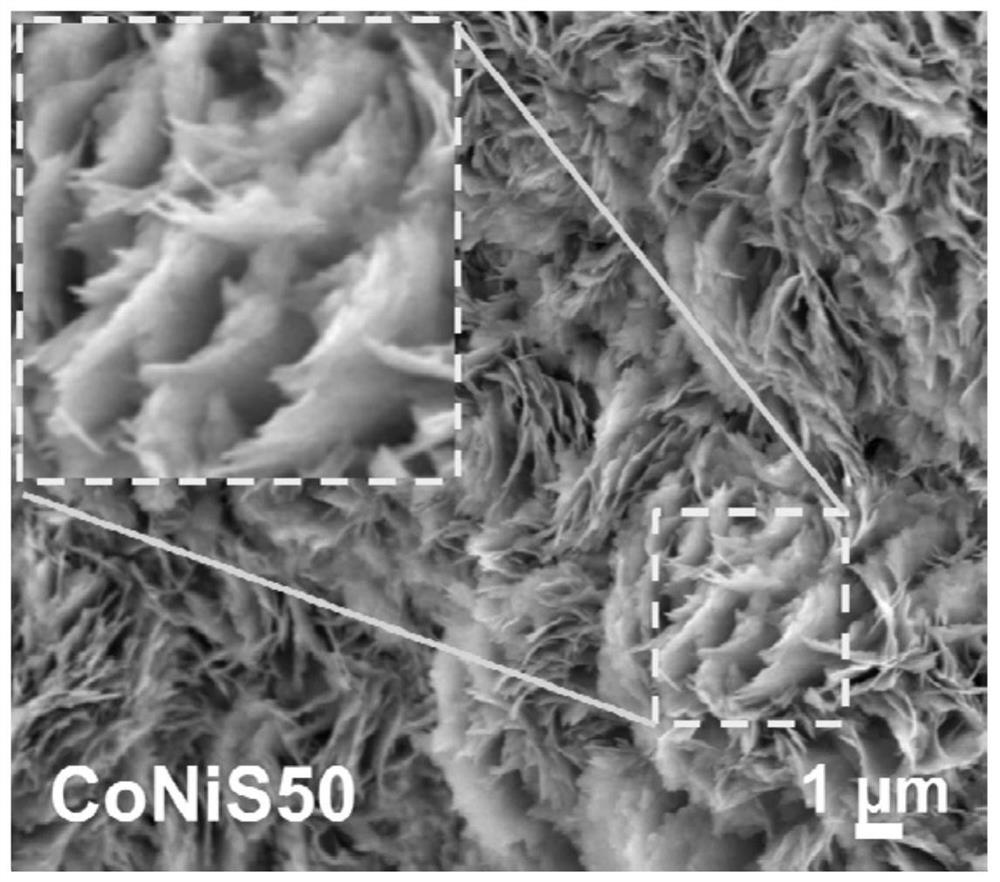

[0038](2) Using hydrothermal method to combine 50mg thiourea and 383mg Co(NO3)2·6H2O was dissolved in 36mL of deionized water, stirred into a transparent solution and placed in a 50mL hydrothermal kettle together with foamed nickel (NF), reacted at a temperature of 453K for 12h, after the hydrothermal reaction was completed, it was naturally cooled to room temperature, the reactants Rinse it several times with deionized water and absolut...

Embodiment 3

[0042]A preparation method of a bimetallic sulfide composite electrocatalyst includes the following steps:

[0043](1) First set the area to 0.25cm2The nickel foam (NF) is soaked in acetone for 1h to remove impurities, and then treated with a 3mol / L hydrochloric acid aqueous solution for 2h to remove the surface nickel oxide layer. After the treatment, the foam nickel (NF) is washed with deionized water and ethanol, and finally placed It is dried in a vacuum drying oven at a temperature of 313k for 6-12 hours to obtain a pretreated foamed nickel sample.

[0044](2) 100mg thiourea and 383mg Co(NO3)2·6H2O was dissolved in 36mL of deionized water, stirred into a transparent solution and placed in a 50mL hydrothermal kettle together with foamed nickel (NF), reacted at a temperature of 453K for 12h, after the hydrothermal reaction was completed, it was naturally cooled to room temperature, the reactants Rinse it several times with deionized water and absolute ethanol. Finally, the reacted prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com