Tire for two-wheeled vehicle and manufacturing method of the same

A two-wheeled vehicle and tire technology, applied in motorcycle tires, tire parts, tire treads/tread patterns, etc., can solve the problems of time-consuming, large tread rubber thickness, and productivity damage, and prevent wrinkling. , Improve uniformity and ensure the effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the invention will now be described with reference to the illustrated embodiments.

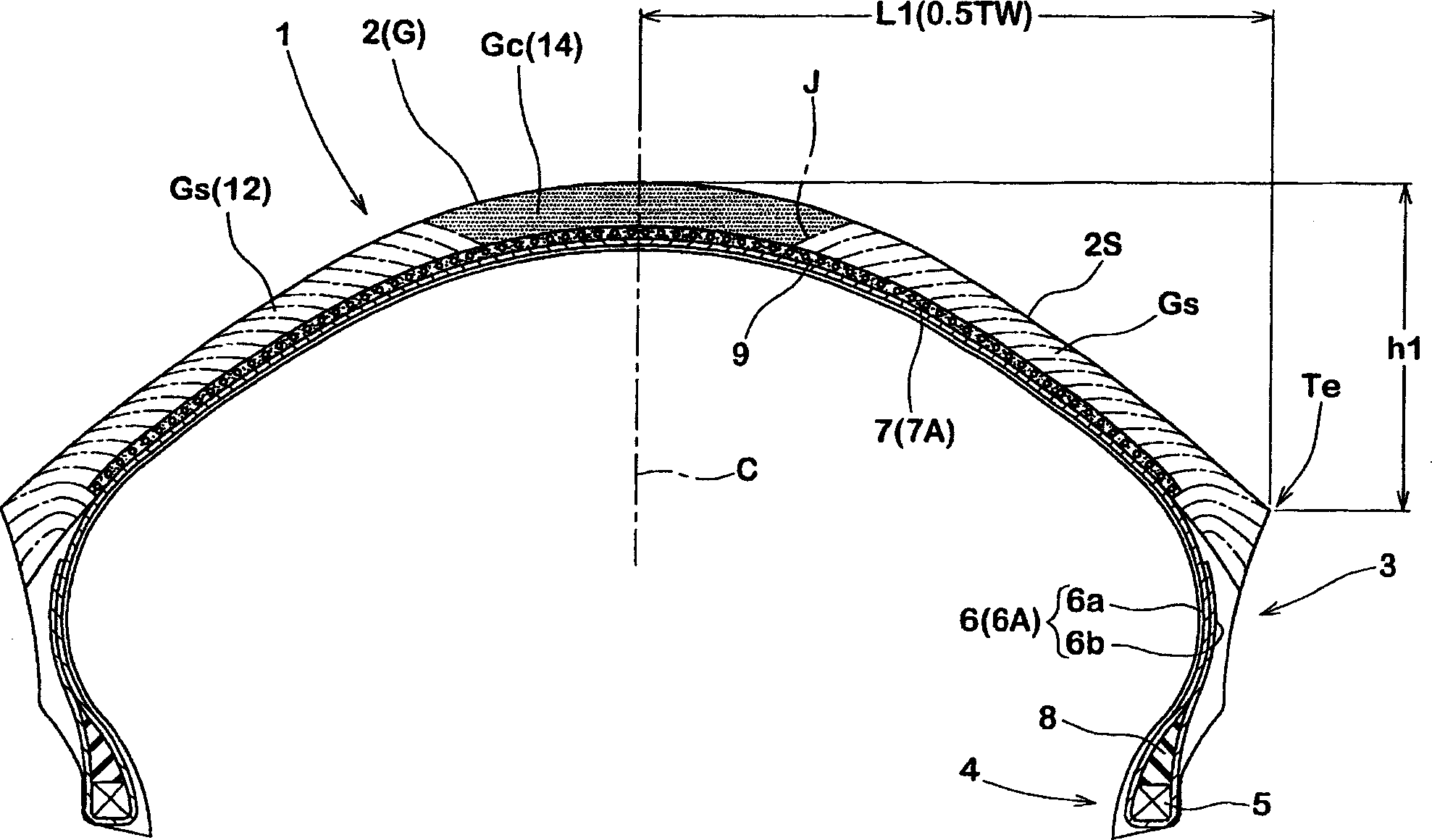

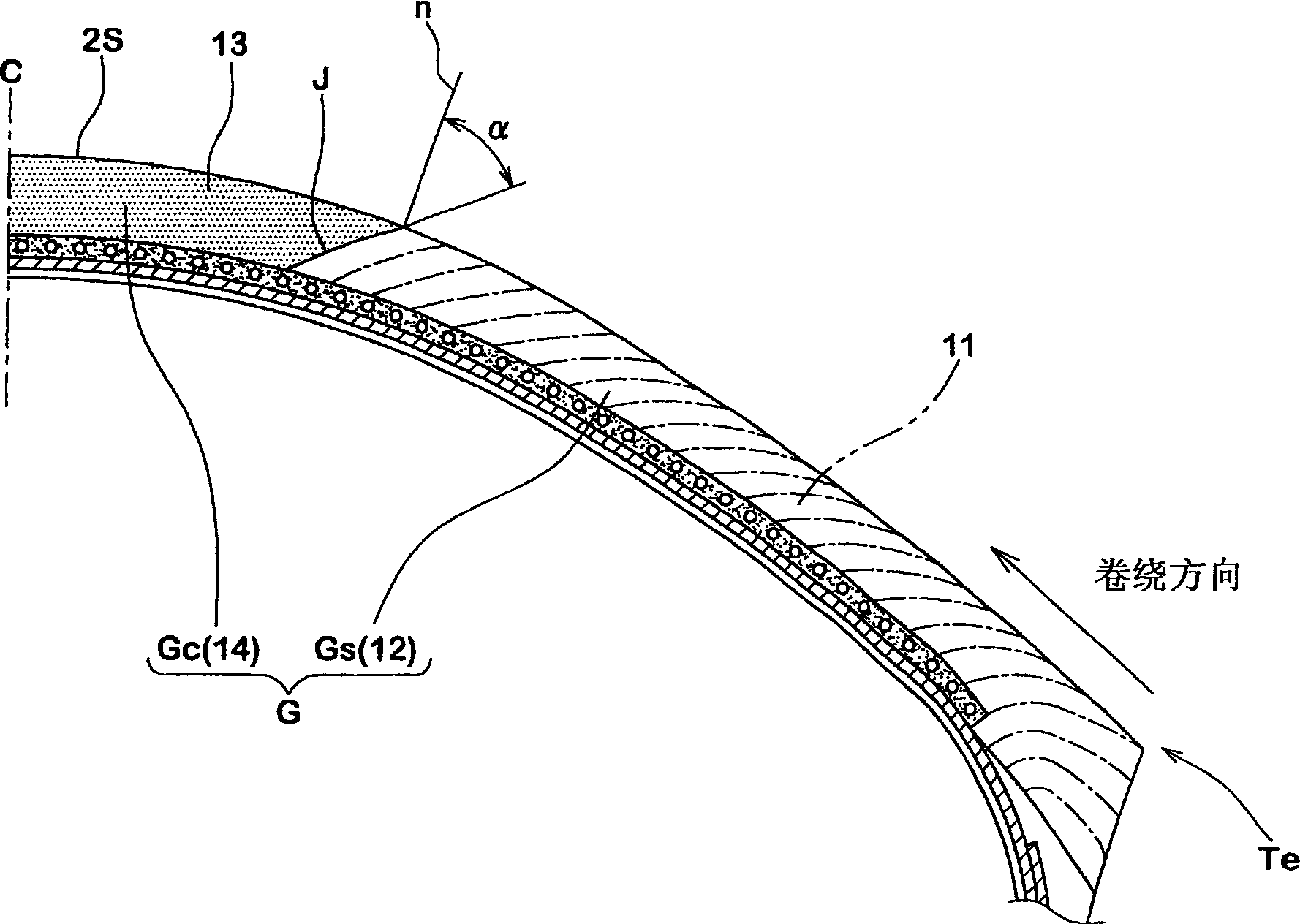

[0028] Such as figure 1 and 2 As shown, a tread surface 2S of a tire 1 for a two-wheeled vehicle includes a tread portion 2 extending from a tire equator line C toward a tread end Te while being curved in a convex arc shape. Since the tread width TW (which corresponds to the tire axial distance between the tread ends Te and Te) contains the maximum tire width, cornering movements can be performed at large lean angles. This embodiment shows a preferred embodiment in which the curvature value h1 / L1 of the tread surface 2S, that is, the tire axial width L1 (=0.5 The ratio h1 / L1 of TW) to the tire radial height h1 is limited to 0.3 to 0.7.

[0029] The tire 1 for a two-wheeled vehicle further includes: a carcass 6 extending from the tread portion 2 through the sidewall portion 3 to the bead core 5 of the bead portion 4; and a belt layer 7 provided on the tread portion 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com