Roaster feed and its preparation method

A technology for suckling pig feed and raw materials, which is applied in the field of suckling pig feed and its preparation, can solve the problems of insufficient powder feed intake, high water content in the product, easy to become soft and sticky, etc. The effect of good palatability and high nutrient concentration in pigs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The suckling pig feed of the present invention and its production process will be further described below in conjunction with the examples, taking the percentage by weight of the suckling pig feed raw materials as the unit, wherein each component is respectively:

[0025] Expanded Soybean Flour 8%, Soy Protein Isolate 5%,

[0026] Plasma protein powder 3%, fish meal 2%,

[0027] Whey Powder 30%, Puffed Corn 15%,

[0028] Emulsified fat 8%, glucose 10.4%,

[0029] Acidulant 2%, calcium hydrogen phosphate 2.5%,

[0030] trace elements trace, vitamins trace,

[0031] Amino Acid Trace, Moisture 14%,

[0032] The acidulant is citric acid.

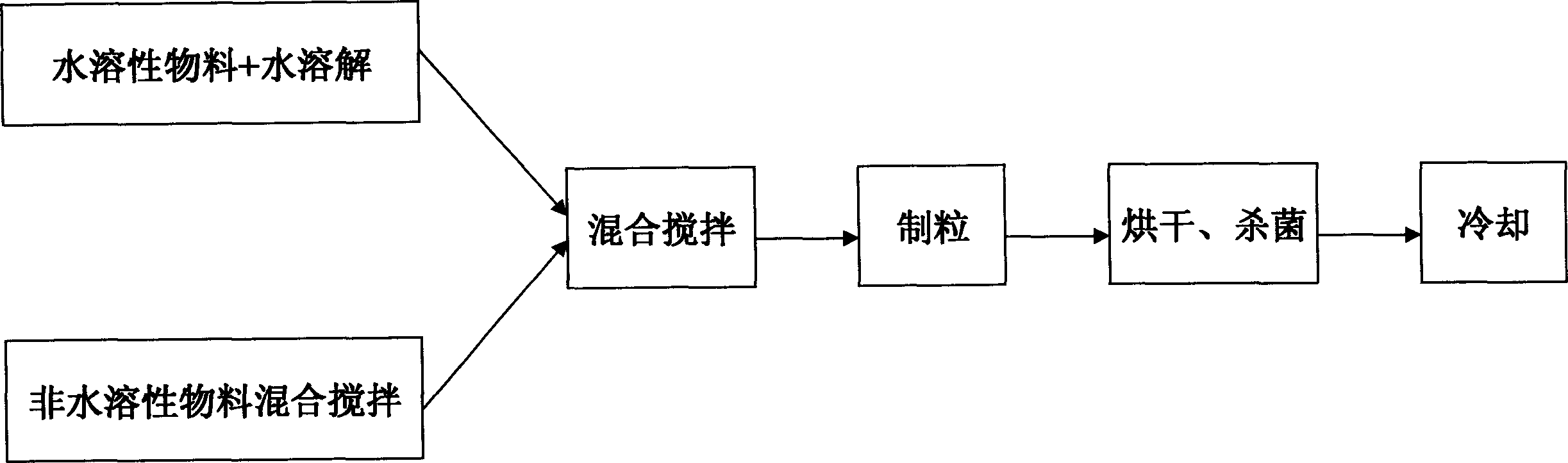

[0033] see figure 1 Shown, a kind of preparation method of suckling pig feed is as follows:

[0034] (1) Weigh 14% water, dissolve the soluble materials plasma protein powder, whey powder, emulsified fat, glucose, citric acid, trace elements, vitamins, amino acids, mix the remaining insoluble materials evenly, and finally mix the t...

Embodiment 2

[0039] The weight percentage of feed raw materials for suckling pigs is taken as the unit, and each component is respectively:

[0040] Expanded Soybean Flour 15%, Soy Protein Isolate 8%,

[0041] Plasma protein powder 5%, fish meal 4%,

[0042] Lactose 8%, Puffed Corn 25.9%,

[0043] Emulsified fat 2%, sucrose 5%,

[0044] Acidifier 0.5%, calcium hydrogen phosphate 1.5%,

[0045] trace elements trace, vitamins trace,

[0046] Amino Acid Trace, Moisture 25%,

[0047] The acidulant is fumaric acid.

[0048] see figure 1 Shown, a kind of preparation method of suckling pig feed is as follows:

[0049] (1) Weigh 25% water, dissolve the soluble materials plasma protein powder, lactose, emulsified fat, sucrose, fumaric acid, trace elements, vitamins, amino acids, mix and stir the rest of the insoluble materials evenly, and finally mix the two into doughy;

[0050] (2) adopt rotary granulator to granulate;

[0051] (3) Use a fluidized bed for drying, the inlet air temperatu...

Embodiment 3

[0054] The weight percentage of feed raw materials for suckling pigs is taken as the unit, and each component is respectively:

[0055] Expanded Soybean Flour 10%, Soy Protein Isolate 6%,

[0056] Plasma Protein Powder 4%, Fish Meal 3%,

[0057] Whey Powder 17%, Puffed Corn 16%,

[0058] Emulsified fat 5%, sucrose 15.4%,

[0059] Acidifier 1.5%, Calcium Hydrogen Phosphate 2%,

[0060] trace elements trace, vitamins trace,

[0061] Amino Acid Trace, Moisture 20%,

[0062] The acidulant is propionic acid.

[0063] see figure 1 Shown, a kind of preparation method of suckling pig feed is as follows:

[0064](1) Weigh 20% water, dissolve the soluble materials plasma protein powder, whey powder, emulsified fat, sucrose, propionic acid, trace elements, vitamins, amino acids, mix the rest of the insoluble materials evenly, and finally mix the two Mix and knead into a dough;

[0065] (2) Use a swing granulator to granulate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com