Oil smoke-expelling utensil capable of forming spirally- ascending air current

A spiral rising and oil fume exhaust technology, which is applied in the direction of oil fume removal, household appliances, household heating, etc., can solve the problems of large motor noise, high wind pressure, and overflow, and achieve the effect of reducing load, significant effect, and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

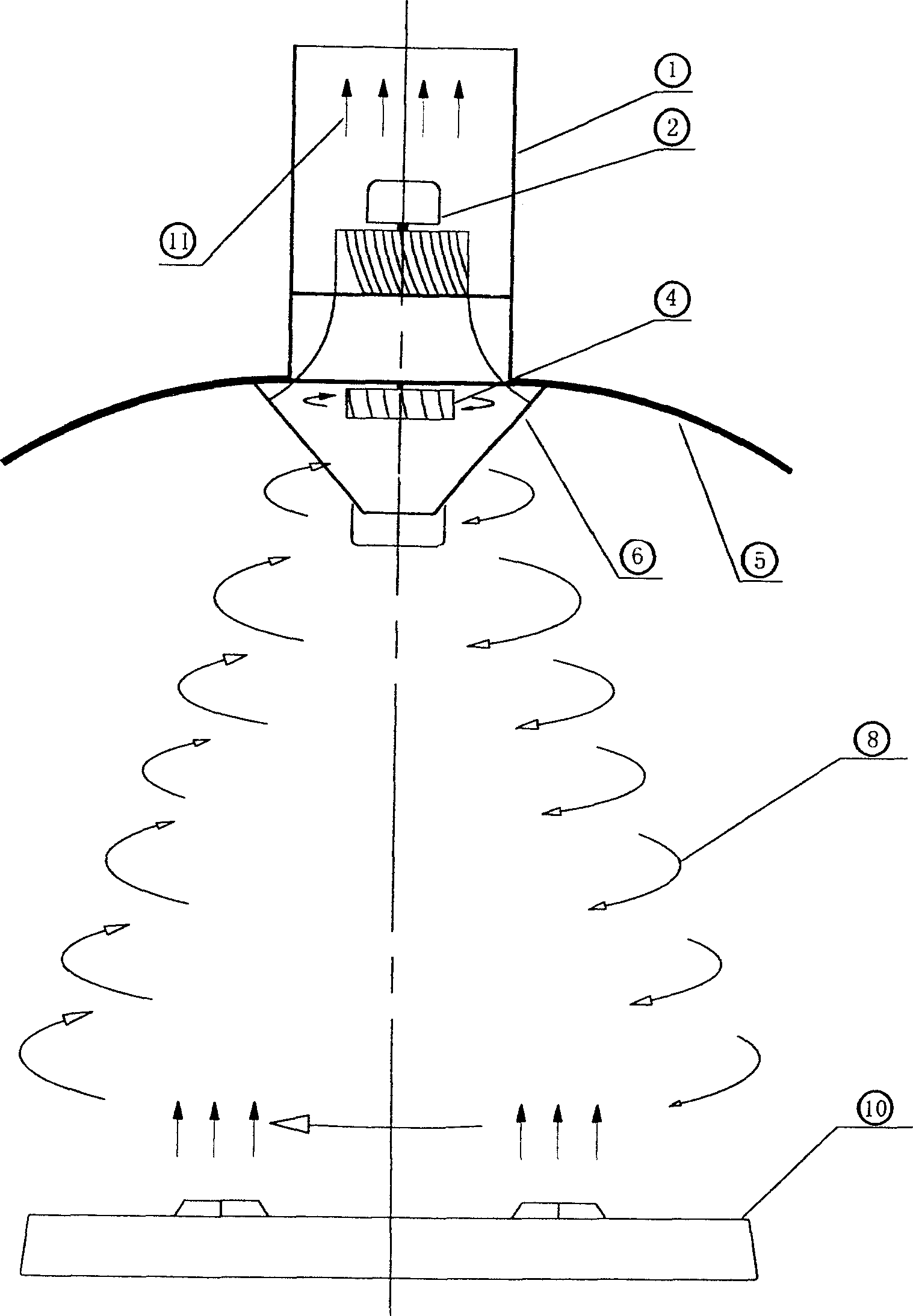

[0016] Example 1: If figure 1 As shown, under the action of the motor 2, the oil fume appliance is at the lower air inlet of the air duct 1 of the oil fume exhaust appliance. A side power vane 4 is installed, and the side power vane 4 starts to rotate through the airflow sucked by the motor 2 to generate the effect of side wind force, thus realizing the purpose of side power. Then because the kitchen stove 10 produces a large amount of water vapor and oil fume 9 when the fuel burns and cooks, it continuously flows upwards. Therefore, there are two conditions for locally forming the tornado effect, and the original uplift force and side power can be added to form a spiral upward airflow that approximates the tornado effect.

example 2

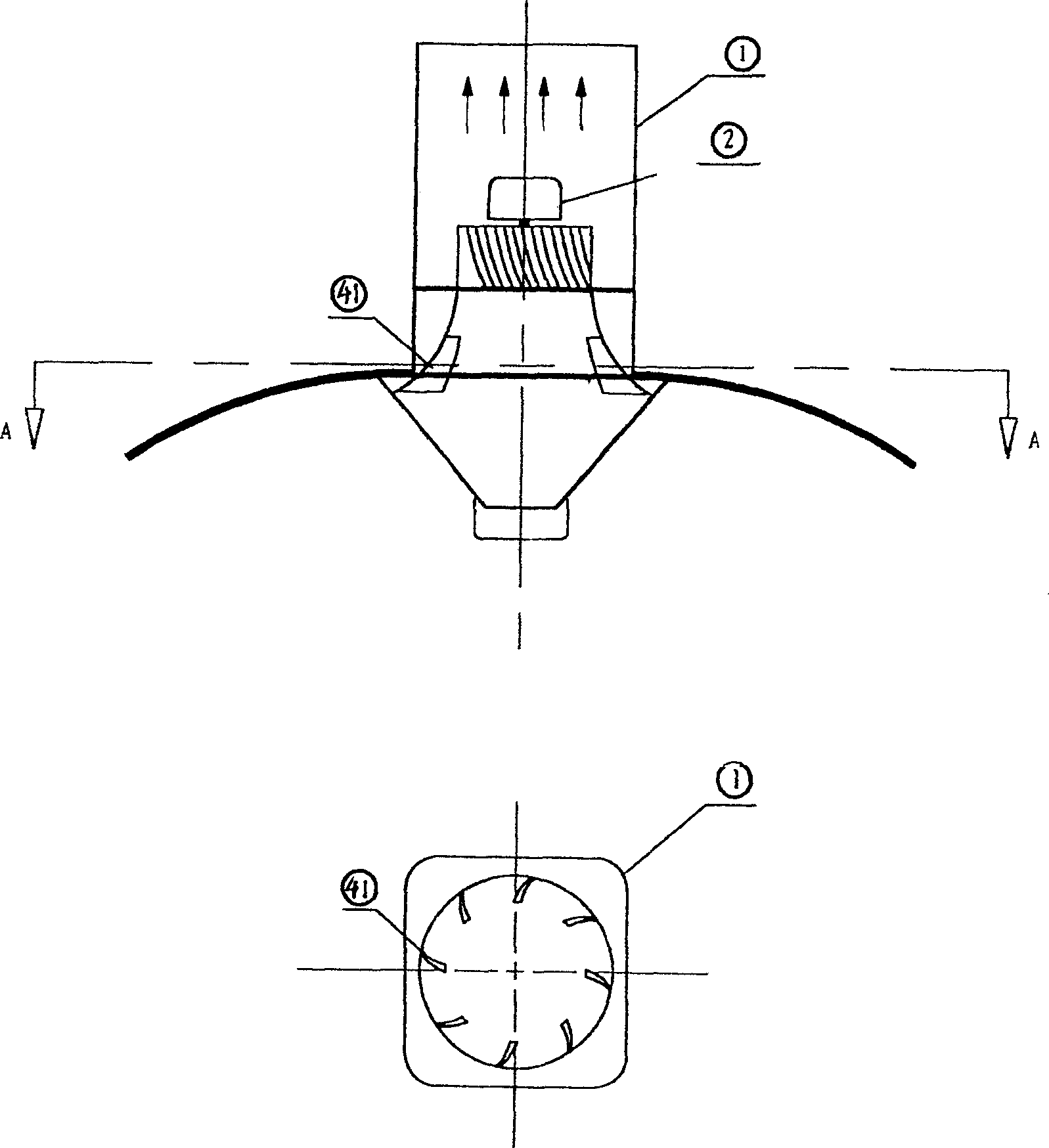

[0017] Example 2: If figure 2 As shown, the top is a schematic diagram of the structure, and the bottom is the A-A diagram. To realize the spiral upward airflow, two necessary conditions must be met, one is the upward force of the traction airflow. The 2nd, side power (biasing force), traction airflow lifting force all possesses at present. Then, by spot-welding the iron sheet 41 similar to the turbine vane on the periphery between the lower air inlet of the air duct 1 of the oil fume exhaust device and the fume collecting hood, the wind force of the inhaled airflow when flowing is decomposed and becomes a lateral force , so the purpose of side power can also be achieved.

example 3

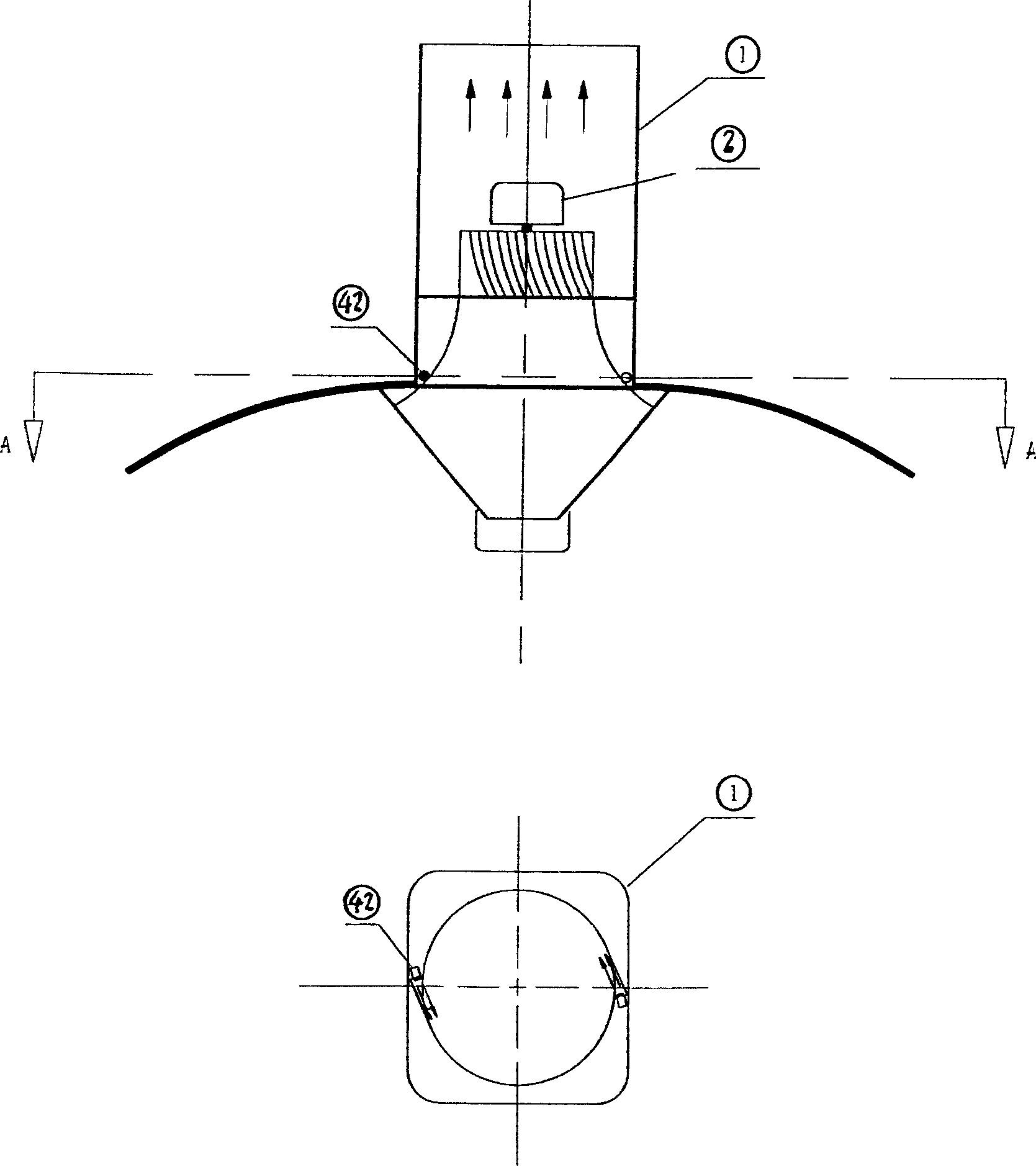

[0018] Example 3: If image 3 As shown, the top is a schematic diagram of the structure, and the bottom is the A-A diagram. To realize the spiral upward airflow, two necessary conditions must be met: the one is the lifting force of the traction airflow, and the other is the side power (biasing force). At present, the lifting force of the traction airflow has been possessed, so then at the lower air inlet of the oil fume exhaust appliance air duct 1, two (or more than two) side air intake motors 42 are symmetrically arranged on the air duct wall, and its air duct is along the main The tangential direction arrangement of the air duct circumference can also realize side power. In addition, other conditions are possessed equally, so the spiral updraft of approximate tornado effect can also be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com