Processing method for silk georgette knitted fabric

A processing method and technology for knitted fabrics, which can be applied to knitted fabrics, textiles and papermaking, etc., can solve the problems of large yarn consumption, quality degradation of silk knitted products, and increased end breakage rate, so as to meet design requirements and prevent untwisting phenomenon. , The effect of reducing the difficulty of weaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The main technological process of the silk georgette knitted fabric of the present invention is: raw material, twisting, knitted fabric weaving, pretreatment, dyeing, finishing, inspection, and finished product. The specific operation process is as follows:

[0014] 1. Raw materials

[0015] Choose two pieces of 6A-grade raw silk, the fineness is 20 / 22 (denier), the surface of the silk is clean, the cleanliness is good, and the raw silk monofilament has good elasticity.

[0016] 2. Twisting

[0017] Twisting the above raw silk on a twisting machine or a twisting device, one is a right-twisted yarn with a twist of 2700 twists / m, and the other is a left-twisted yarn with a twist consistent with that of a right-twisted yarn. In the technical solution of the present invention, the twist is required to reach 2700-3000 twists / m. If the twist is lower than 2700 twists / m, the georgette crepe effect and elasticity of the silk georgette knitted fabric are poor.

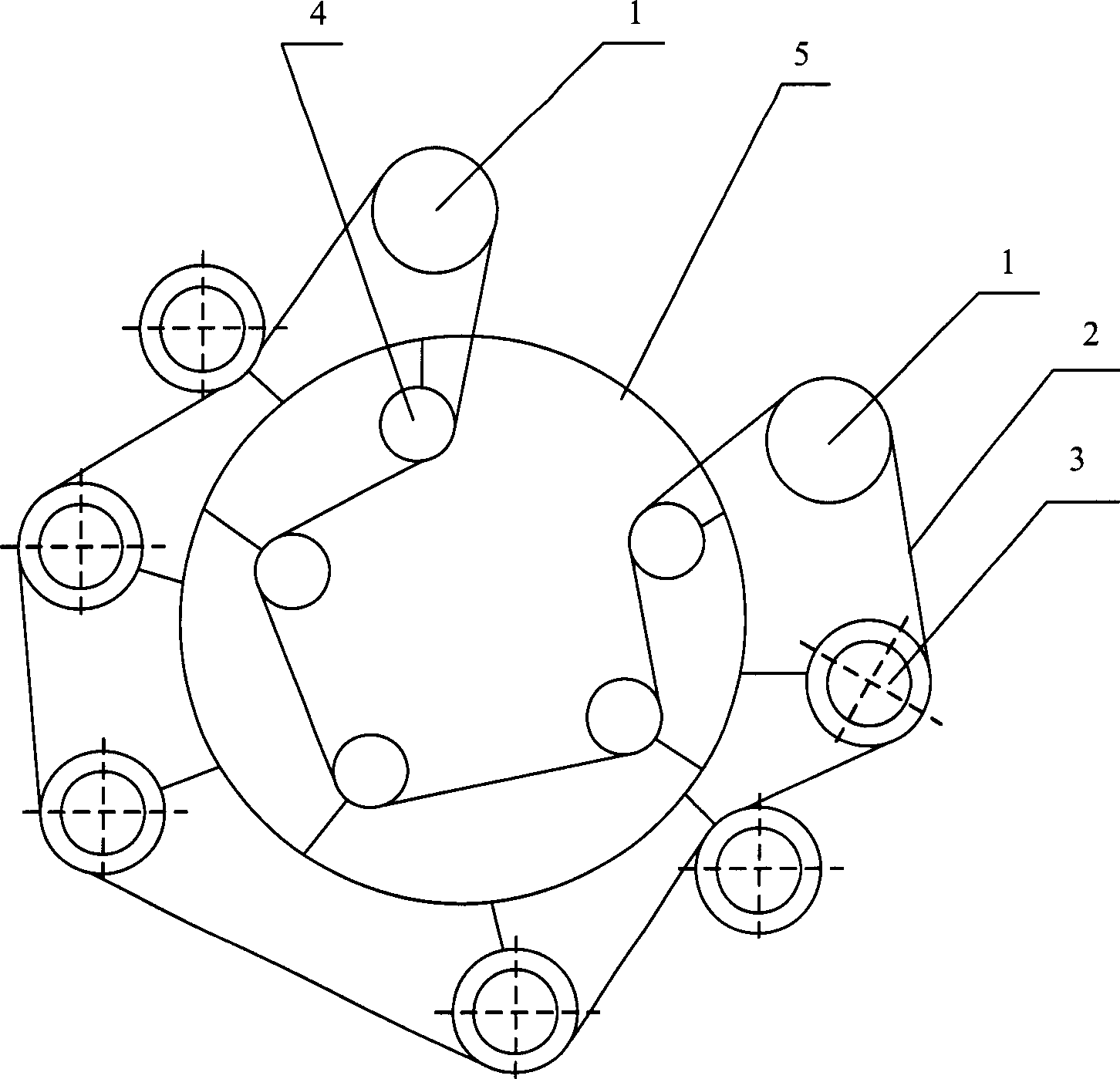

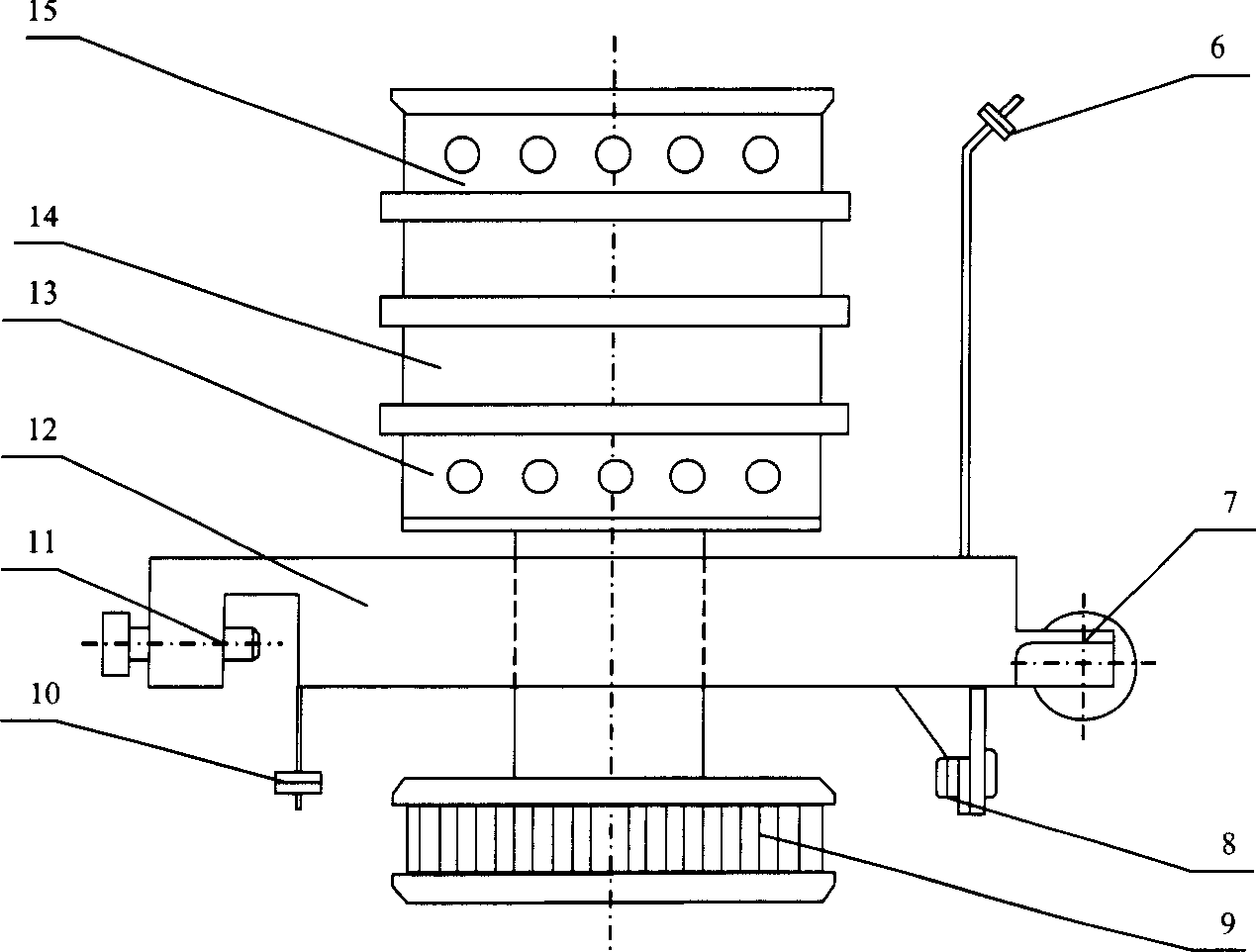

[0018] 3. Wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com