Zinc bath bottom slag cleaning device

A technology for cleaning devices and zinc pots, applied to descaling devices, coatings, furnace components, etc., can solve the problems of low cost, inconvenient operation, complex structure, etc., and achieve the effects of increasing productivity, simple structure, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

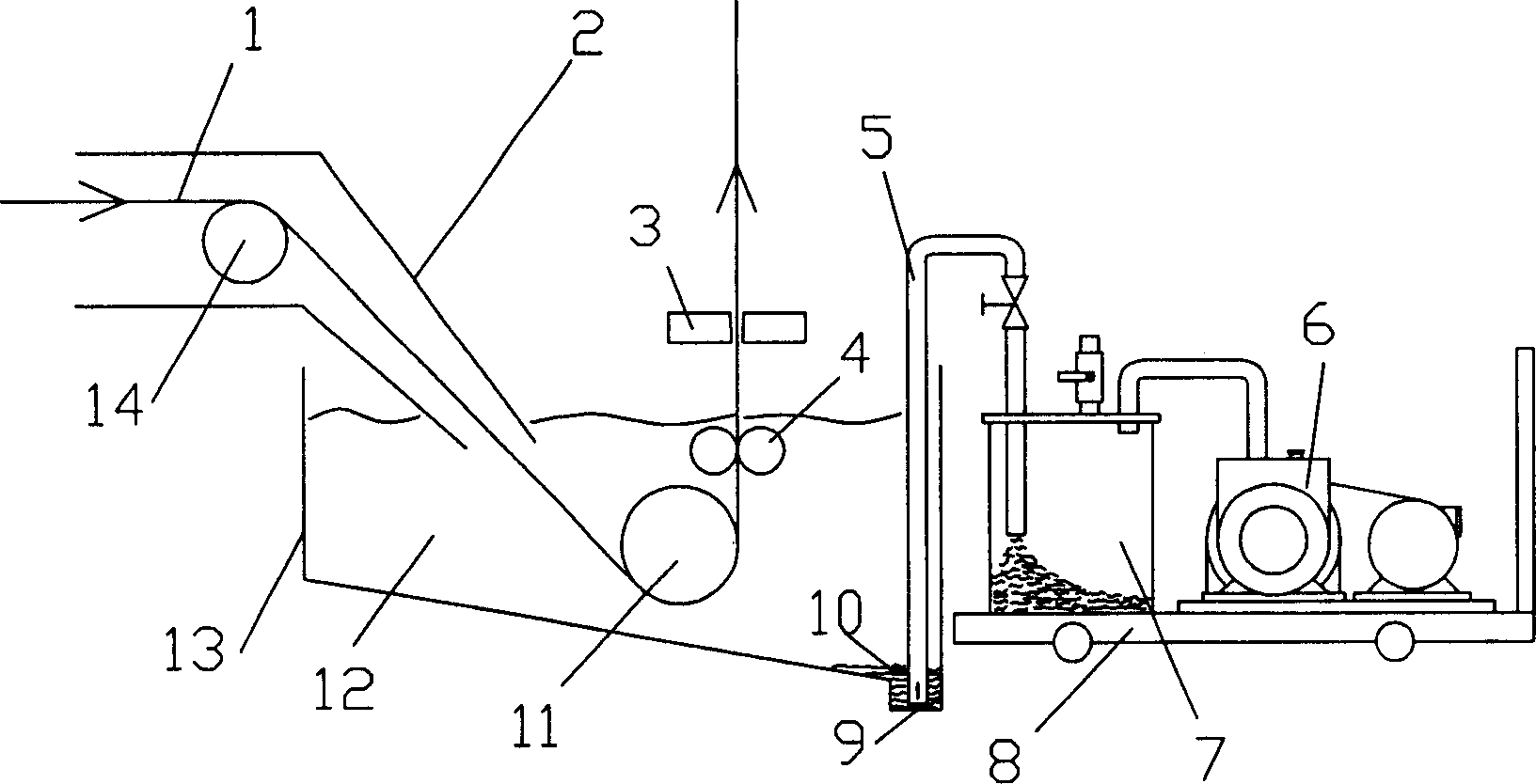

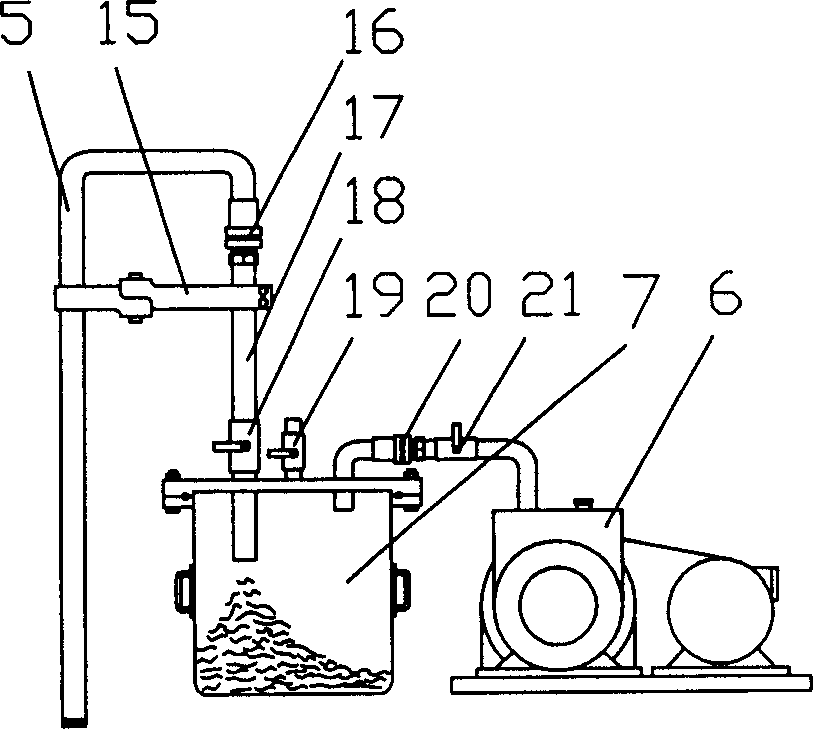

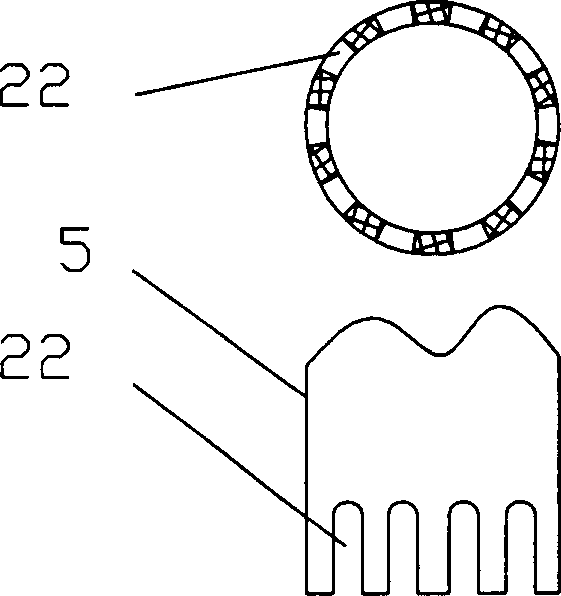

[0019] see figure 1 , figure 2 , a zinc pot bottom slag cleaning device, including slag introducing pipe parts, a vacuum chamber 7 and a vacuum pump 6. The slag introduction pipe components include slag introduction pipe 5, quick joint 16, slag discharge pipe 17 and stop valve 18. The slag discharge pipe 17 is connected to the stop valve 18 and extends into the vacuum chamber 7. The slag pipe 5 and the slag introducing pipe 5 extend into the bottom of the zinc pot 13, and the head of the slag introducing pipe 5 is comb-shaped, which is used as the bottom slag suction port 22, see image 3 . The slag introducing pipe 5 and the slag discharging pipe 17 can be quickly connected and disassembled through the quick connector 16, and the slag introducing pipe 5 is fixed with a pipe clamp 15.

[0020] see Figure 4 , figure 2 , the vacuum chamber 7 is made up of a vacuum chamber body 27, a sealing cover 23, a sealing ring 25, and mounting bolts 24. There are three holes on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com