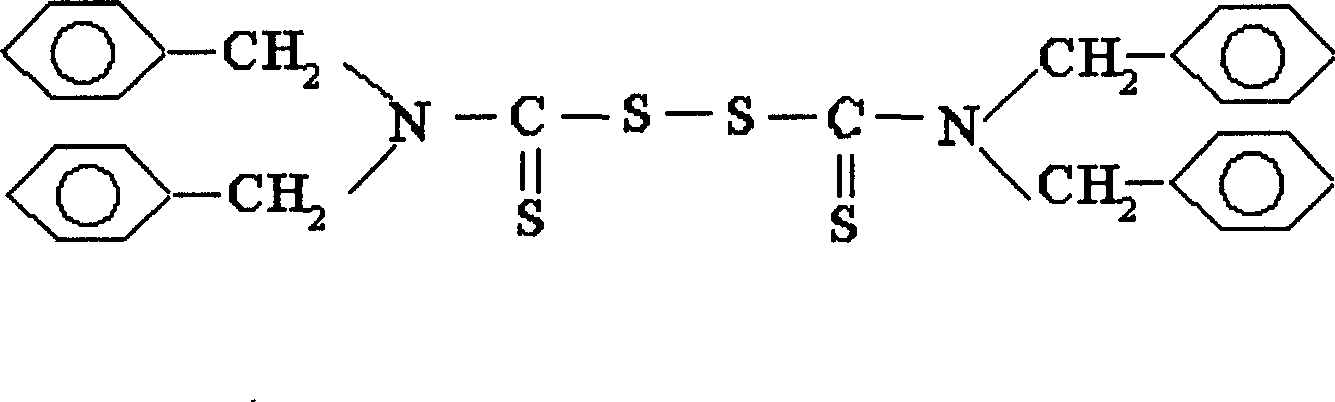

Process for preparing tetra-benzyl thiram disulfide

A technology of tetrabenzylthiuram disulfide and carbon disulfide, applied in the direction of organic chemistry, etc., can solve the problems of unsuitable tetrabenzylthiuram disulfide, high equipment requirements, unfavorable environmental protection, etc., and achieve easy industrial implementation and environmental protection No pollution, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

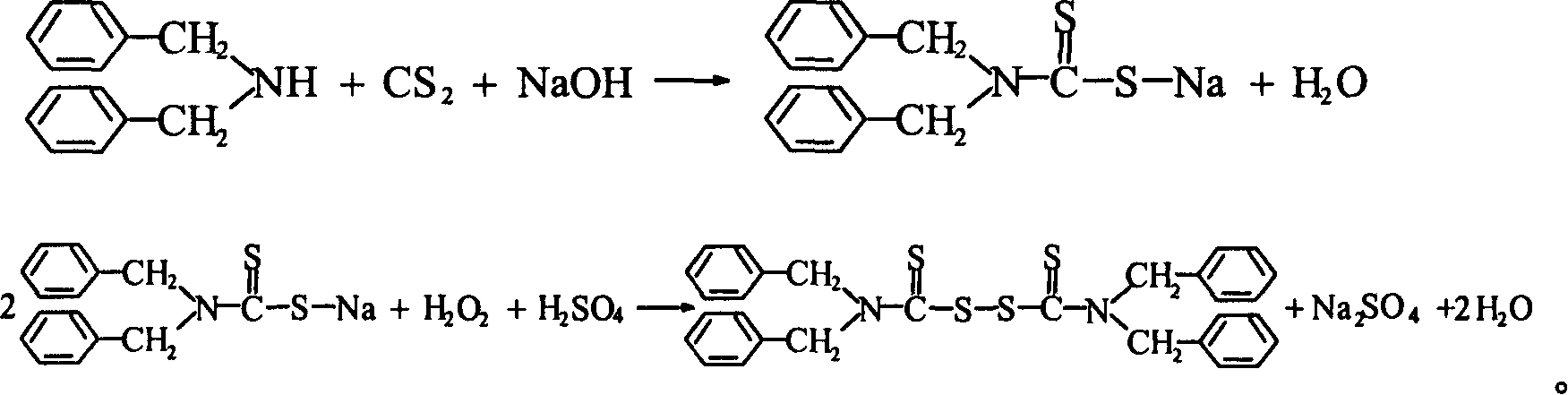

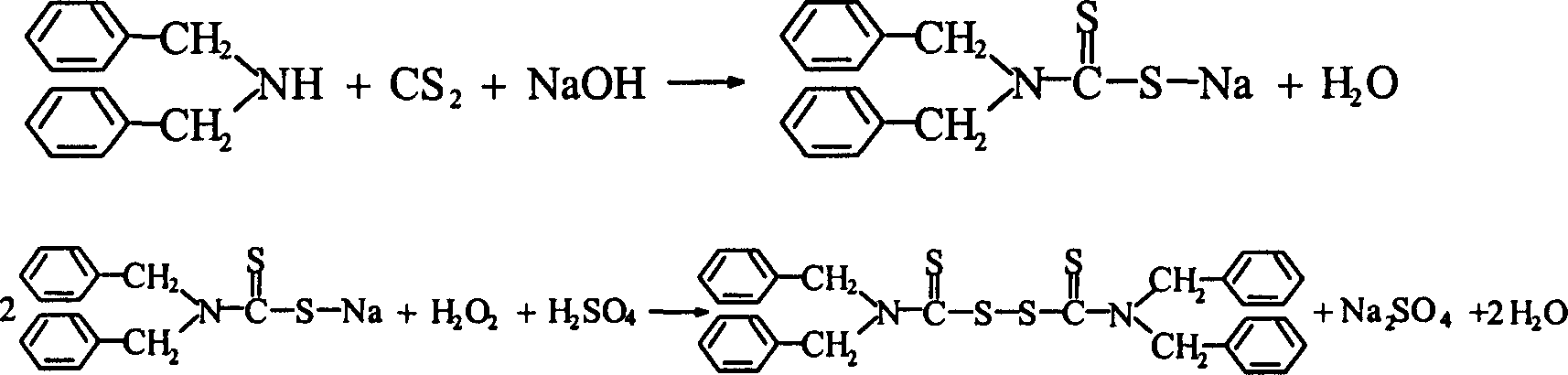

Method used

Image

Examples

Embodiment 1

[0020] Add 10.1g of sodium hydroxide and 300g of water into the reactor and stir to dissolve, then add 49.3g of dibenzylamine, stir evenly, start to add 20g of carbon disulfide dropwise, control the reaction temperature at 40°C, and continue stirring for 4h after the dropwise addition is completed. Dilute 19g of 27.5% hydrogen peroxide to 100g with water, and dilute 16g of 98% sulfuric acid to 200g with water, then add sulfuric acid and hydrogen peroxide dropwise at the same time, and control the temperature at 65°C. The pale yellow precipitate was filtered and dried to obtain 65 g of tetrabenzylthiuram disulfide. The yield is 95%, and the product purity is 97%.

Embodiment 2

[0022] Add 10.1g of sodium hydroxide and 300g of water into the reactor and stir to dissolve, then add 49.3g of dibenzylamine, stir evenly, start to add 20g of carbon disulfide dropwise, control the reaction temperature at 40°C, and continue stirring for 2h after the dropwise addition is completed. 6g of sodium hypochlorite is formulated into a solution with a concentration of 6%, and 16g of sulfuric acid with a concentration of 98% is diluted to 200g with water, then the solution of sulfuric acid and sodium hypochlorite is added dropwise at the same time, and the temperature is controlled at 55°C. After the dropwise addition, the generated The pale yellow precipitate was filtered and dried to obtain 62 g of tetrabenzylthiuram disulfide.

[0023] The yield is 91%, and the product purity is 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com