Nozzle for micro and nano material preparation by interior mixing supercritical fluid

A supercritical fluid, internal mixing technology, applied in the direction of liquid injection devices, injection devices, etc., can solve the problems of limited number of nozzles, easy blockage, large measurement and detection errors, etc., to save costs, not easy to block, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

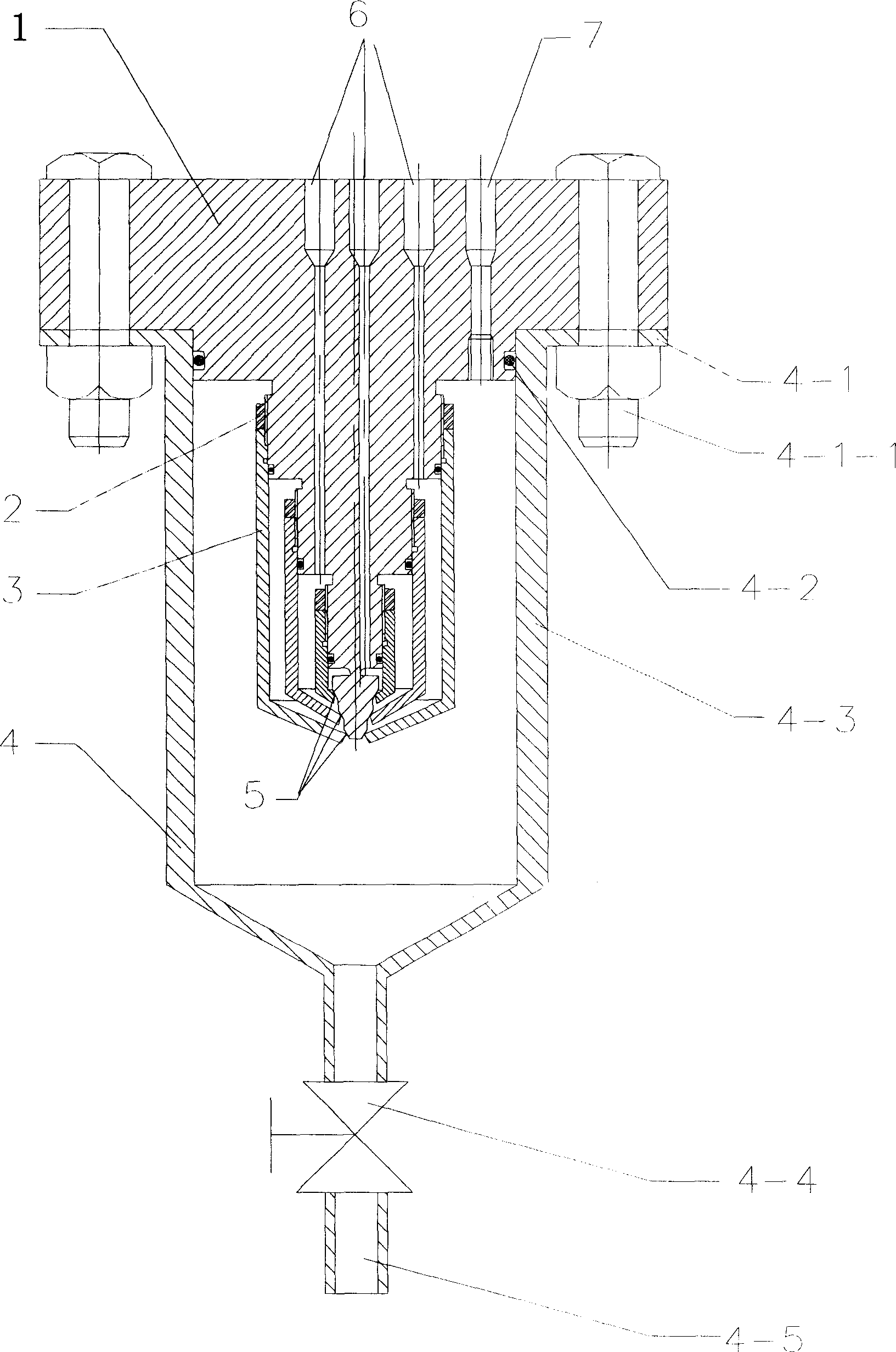

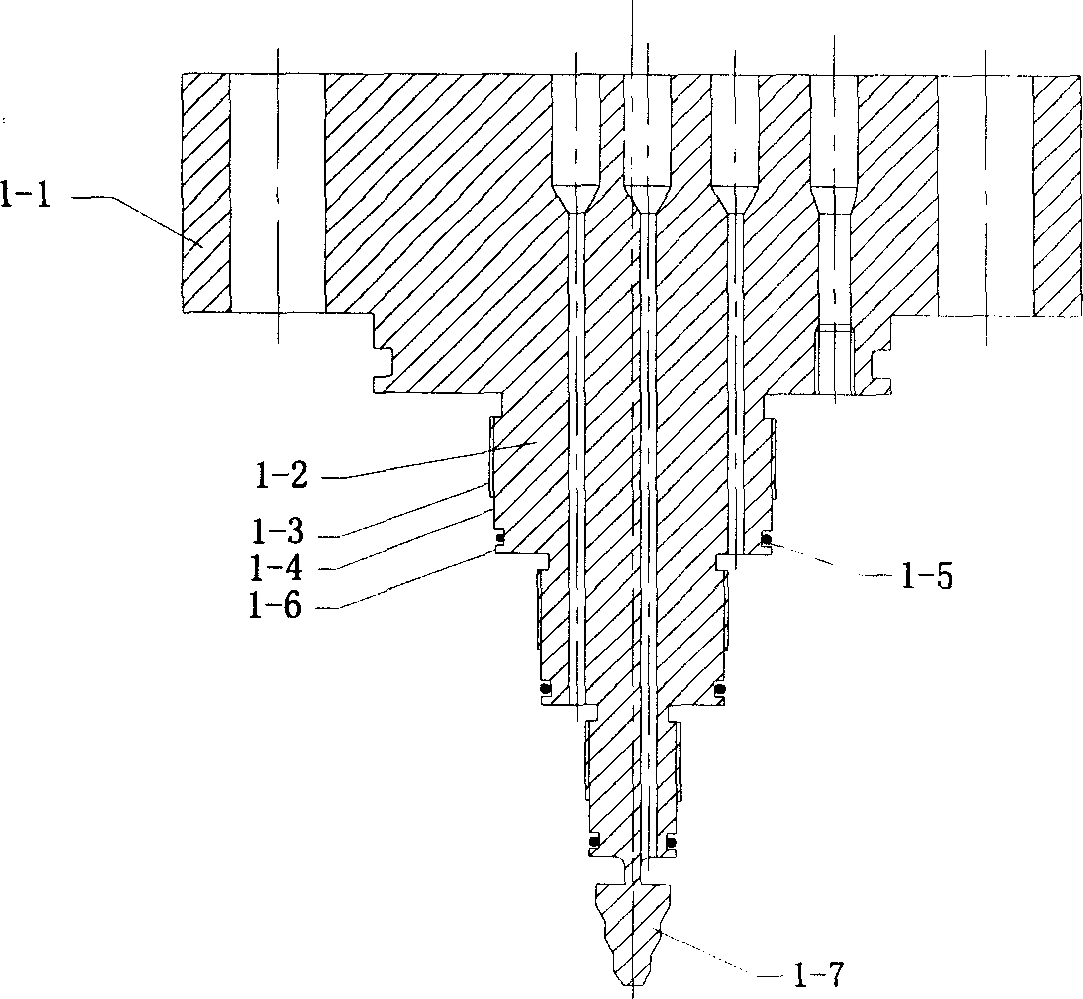

[0018] As shown in Figure 1, it is a nozzle with three layers of tapered end sleeves 3. There are three stepped structures 1-2 on the nozzle body 1, and each stepped structure has threads 1-3, positioning surface 1-4 and sealing surface 1-6. The sealing surface 1-6 is a sealing groove structure to install the seal 1-5, the seal 1-5 adopts an "O"-shaped rubber ring to ensure the sealing of the nozzle body 1 and the cone end sleeve 3; there are three sections of gradually increasing cones on the nozzle core 1-7, which are integrated with the nozzle body 1. ; The nozzle body 1, the sealing structure 1-1, and the collector 4 and the sealing structure 4-1 all adopt the flange flat cover structure, which is connected by bolt fasteners 4-1-1, and the seal 4-2 adopts "O" In order to ensure a good sealing effect, a sealing groove is opened at the position where the sealing element 4-2 is arranged in the sealing structure 1-1; the valve 4-4 at the discharge port of the collector 4 adopts a ...

Embodiment 2

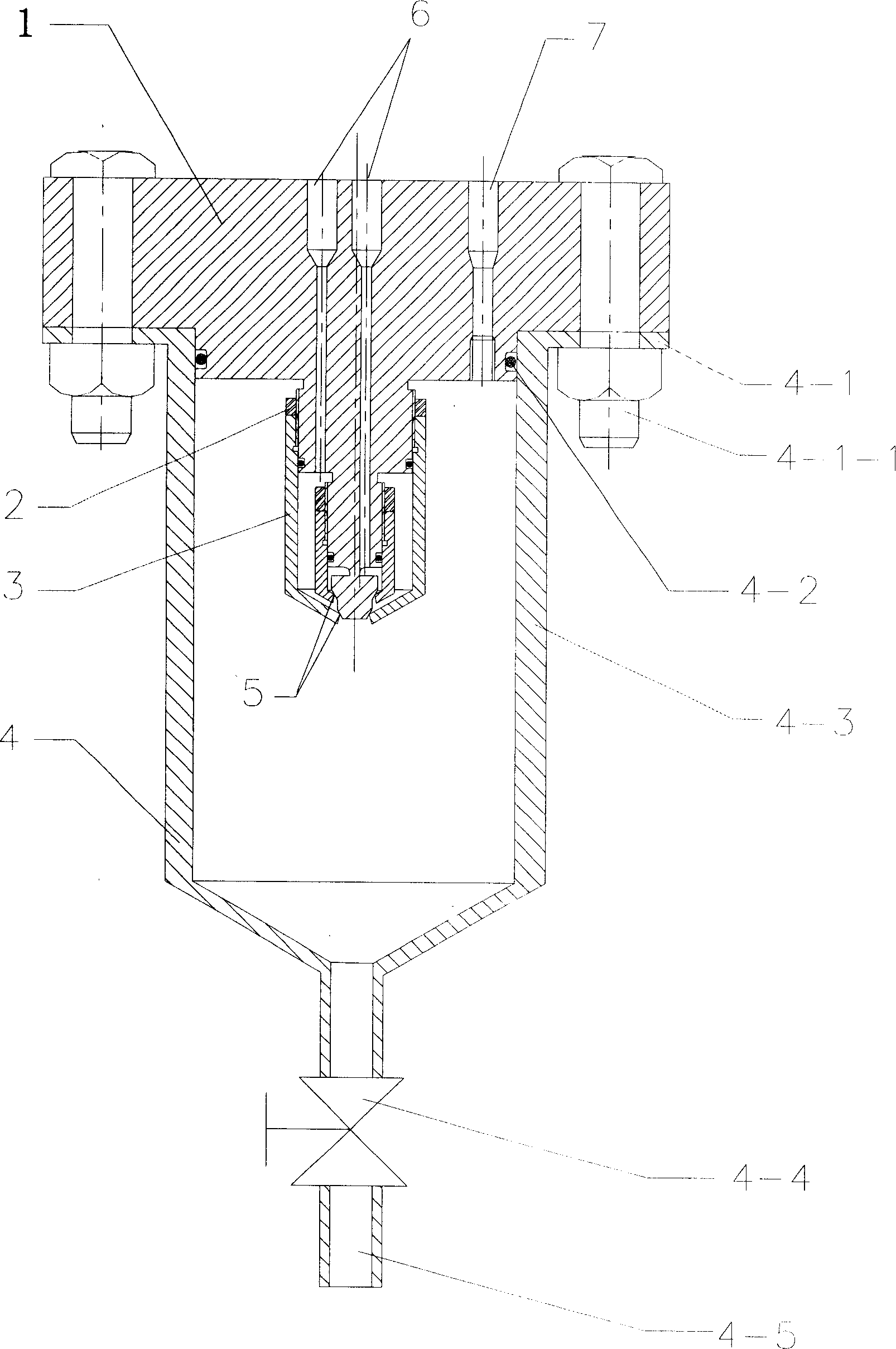

[0022] Such as image 3 Shown is a nozzle with two layers of tapered end sleeves 3, and the others are the same as the first embodiment.

Embodiment 3

[0024] Such as Figure 4 Shown is a nozzle with four layers of tapered end sleeves 3, and the others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com